muuqaal

Profile

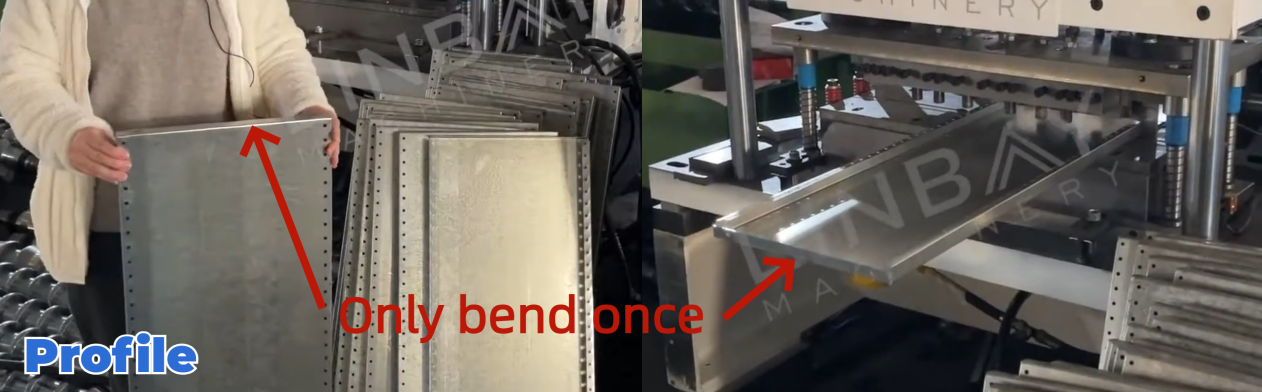

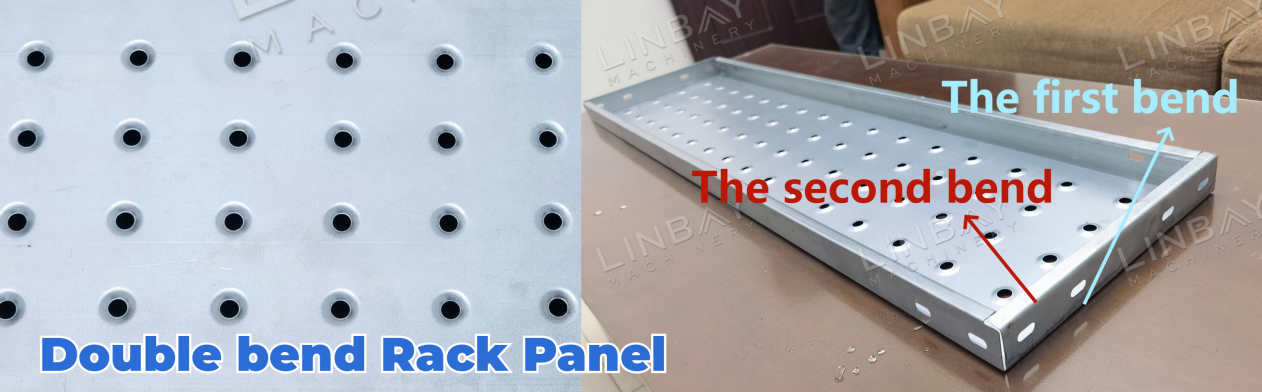

Qalabka shelf waa qayb muhiim ah oo ka mid ah nidaamka rarista, oo loogu talagalay in lagu hayo alaabta. Guud ahaan waxa laga sameeyaa bir galvanized ah oo dhumucdeedu u dhaxayso 1 ilaa 2 millimitir. Gudidan waxa laga heli karaa ballac iyo dherer kala duwan, halka jooggiisuna uu yahay mid joogto ah. Waxa kale oo ay ka kooban tahay hal laabasho oo dhinaca ballaadhan ah.

Kiis-dhabta dhabta ah-Habeelayaasha Farsamo ee ugu muhiimsan

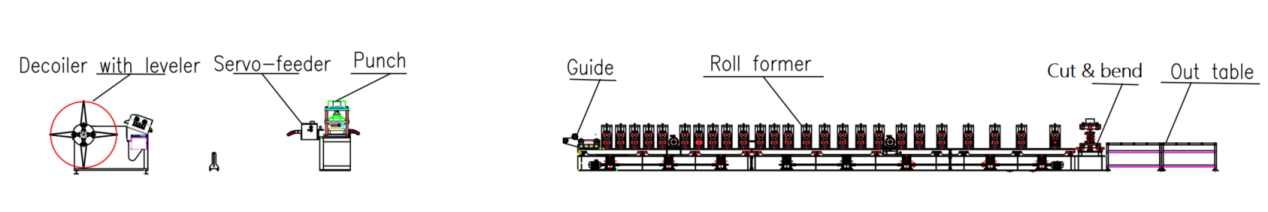

Jaantuska socodka

Decoiler Hydraulic oo leh heerkulbeeye--Fadiyaha Servo--Foodhka Haydarooliga--Hagaha--Mashiinka samaynta-- Goynta iyo Mashiinka foorarsiga--Miiska bannaanka

Halbeegyada Farsamo ee ugu muhiimsan

1. Xawaaraha khadka: La hagaajin karo inta u dhaxaysa 4-5 m/min

2. Profiles: Balac iyo dherer kala duwan, oo leh joog joogto ah

3. Dhumucda alaabta: 0.6-1.2mm (codsigan)

4. Qalabka ku habboon: birta kulul ee kulul, birta qabow ee duuban

5. Mashiinka samaynta duub:Cantilevered qaab-dhismeedka guddi labajibbaaran oo leh nidaamka wadista silsiladda

6. Habka goynta iyo foorarsiga: Goynta iyo foorarsiga isku mar ah, oo duubitaanku hore u joogsanayo inta hawsha lagu jiro

7. Hagaajinta cabbirka: Si toos ah

8. PLC cabinet: Siemens system

Sharaxaada kiis-dhabta ah

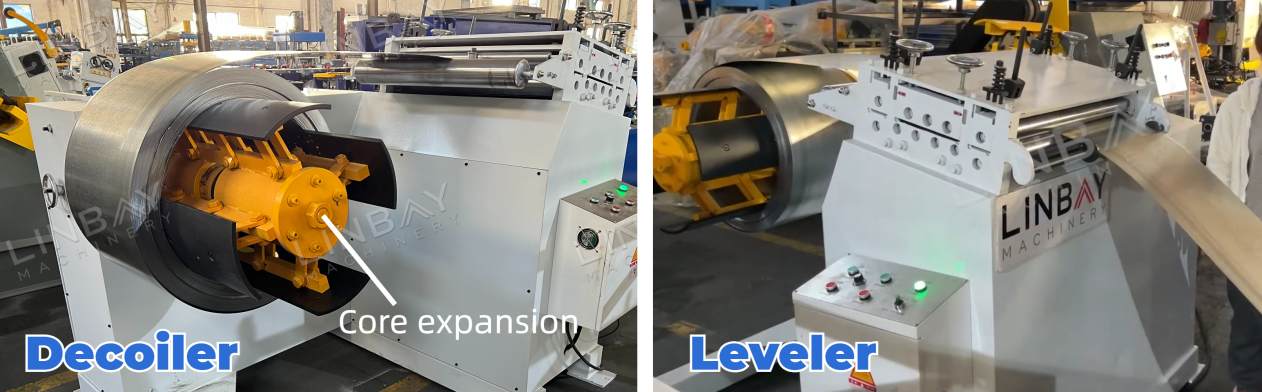

Decoiler Hydraulic oo leh Leveler

Mashiinkaani wuxuu isku daraa qalabka wax lagu nadiifiyo iyo heerka cabbiraha, isagoo wanaajinaya booska sagxada warshadda iyo dhimista kharashka dhulka. Habka ballaarinta xudunta u ah waxay la qabsan kartaa si ay ugu habboonaato gariiradaha birta ee dhexroorka gudaha u dhexeeya 460mm iyo 520mm. Inta lagu guda jiro gariiradda, hayeyaasha gariiradda dibadda waxay xaqiijiyaan in gariiradda birta ahi ay si ammaan ah u jirto, taasoo kor u qaadaysa badbaadada shaqaalaha.

Heeriyuhu waxa uu fidiyaa gariiradda birta ah, isaga oo yaraynaya walbahaarka gudaha oo awood u siinaya feedh iyo duub wax ku ool ah samaynta.

Servo Feeder & Hydraulic Punch

Feer hydraulic wuxuu u shaqeeyaa si madaxbannaan, oo ka duwan saldhigga mashiinka samaynta. Naqshadeyntani waxay u oggolaaneysaa mashiinka samaynta duubista inuu sii wado shaqeynta inta feerku socdo, kor u qaadista waxtarka guud ee khadka wax soo saarka. Matoorka servo wuxuu yareeyaa dib u dhaca bilowga-joojinta, isaga oo siinaya kontorool sax ah dhererka hore ee gariiradda birta ee feedhka saxda ah.

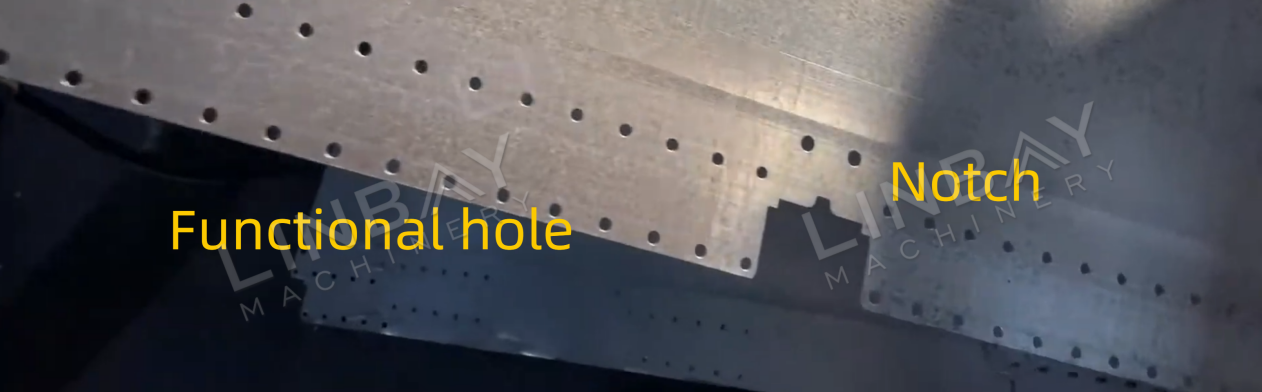

Inta lagu jiro marxaladda feerka, darajo ayaa la abuuraa marka lagu daro godadka shaqeynta ee rakibidda furaha. Mar haddii gariiradda birta fidsan loo qaabayn doono guddi saddex-geesood ah, darajooyinkan si sax ah ayaa loo xisaabiyaa si looga hortago is dulfuulan ama daldaloolo waaweyn oo ka dhaca afarta gees ee guddiga shelf.

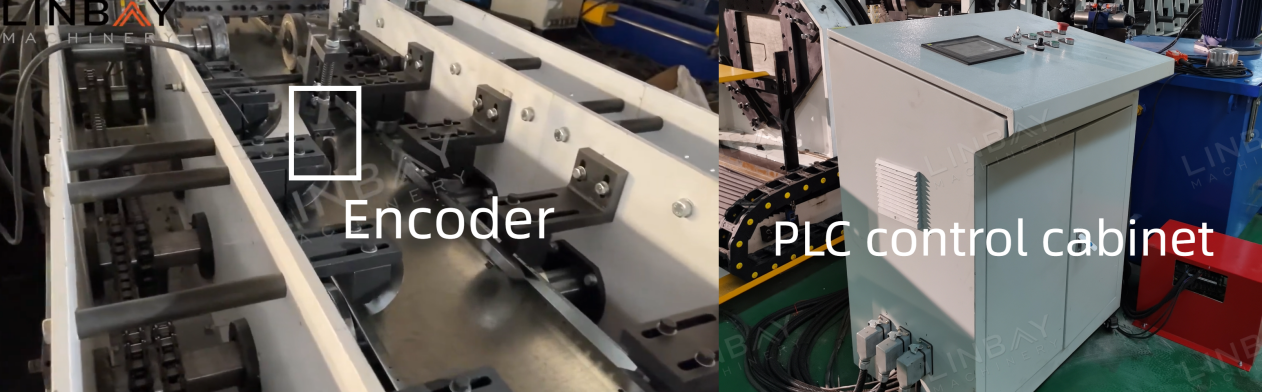

Encoder & PLC

Codeeyuhu wuxuu u beddelaa dhererka la ogaaday ee gariiradda birta oo u beddela calaamad koronto, ka dibna loo gudbiyo golaha kontoroolka PLC. Gudaha golaha xakamaynta, xuduudaha sida xawaaraha wax soo saarka, tirada wax soo saarka, dhererka goynta, iwm, ayaa si sax ah loo maareyn karaa. Waad ku mahadsan tahay cabbirka saxda ah iyo jawaab celinta uu bixiyay codeerku, gooyaha haydarooliga wuxuu ilaalin karaa saxnaanta goynta gudaha±1mm, yaraynta khaladaadka

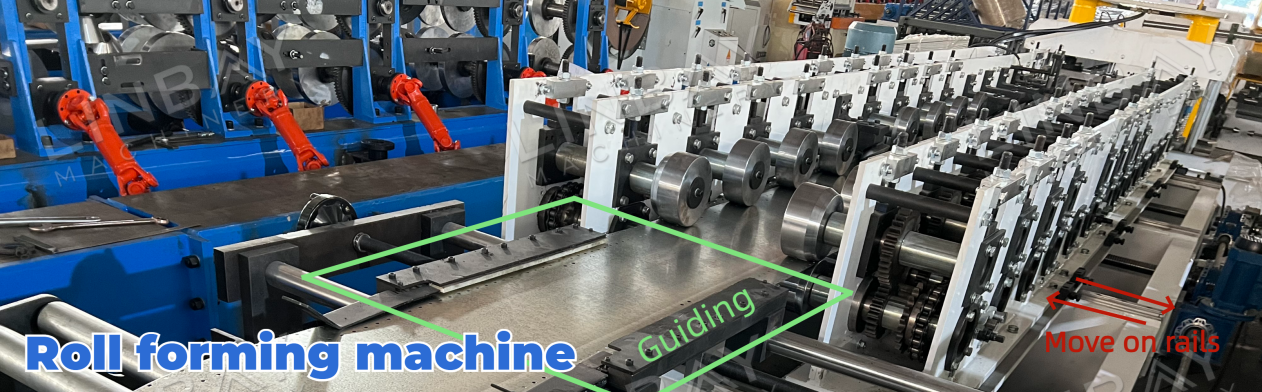

Mashiinka Samaynta Roll

Kahor inta aan la galin mashiinka samaynta, gariiradda birta ah waxaa lagu hagayaa baararka si loo ilaaliyo toosinta dhexda. Marka la eego qaabka shafka, kaliya dhinacyada gariiradda birta ayaa u baahan samaynta. Sidaa darteed, waxaanu shaqaaleysiinaa qaab-dhismeedka gidaarka laba-jibbaaran si loo dhimo isticmaalka alaabta, si loo badbaadiyo kharashyada alaabta rullaluistuyada. Rollers-ka-wadida silsilada waxay cadaadis saarayaan gariiradda birta si ay u fududeeyaan horumarkeeda iyo samayntiisa.

Mashiinka samaynta ayaa awood u leh inuu soo saaro muraayadaha shelf ee ballacyada kala duwan. Marka la geliyo cabbirada la doonayo gudaha guddiga kontoroolka PLC, saldhigga samaynta ayaa si toos ah u hagaajiya booskeeda tareenada marka la helo calaamadaha. Marka saldhigga samaynta iyo rullaluistu dhaqaaqaan, dhibcaha samaynta ee gariiradda birta ayaa isbeddelaya si habboon. Habkani waxa uu awood u siinayaa mishiinka samaynta duudduuban in uu si hufan u soo saaro muraayadaha shelf ee cabbirrada kala duwan.

Codeeye ayaa la rakibay si loo ogaado dhaqdhaqaaqa goobta sameynta, iyadoo la hubinayo hagaajinta cabbirka saxda ah. Intaa waxaa dheer, laba dareemayaal booska-dareemayaasha dibadda iyo gudaha-Waxaa loo shaqeeyaa si looga hortago dhaqdhaqaaqa xad-dhaafka ah ee xadiidka, si looga hortago simbiriirixashada ama isku dhaca rollers-ka.

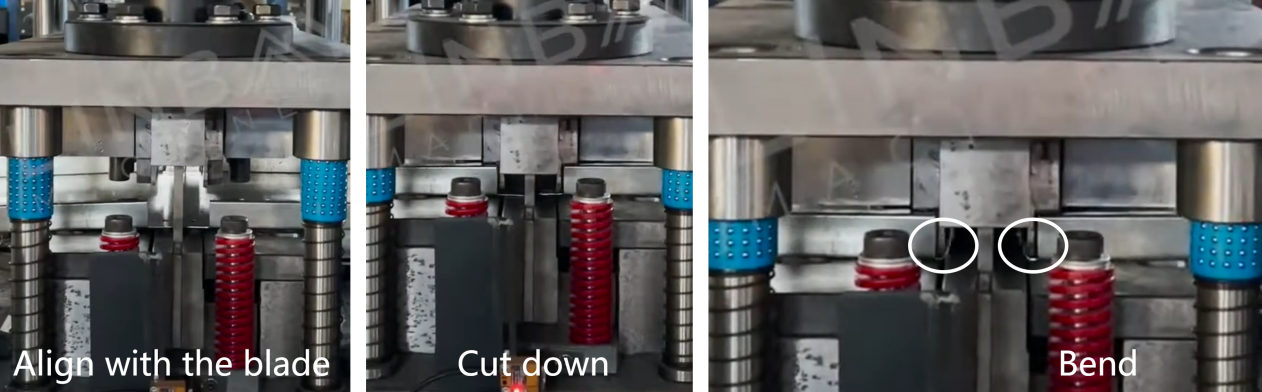

Mashiinka Goynta iyo Laacida

Xaaladdan, halka guddiga shelf uu u baahan yahay hal laabasho oo dhinaca ballaaran ah, waxaan farsameynay mashiinka goynta si uu u fuliyo goynta iyo foorarsiga isku mar ah.

Daabku wuxuu u soo daadaa si uu u sameeyo goynta, ka dib markaa caaryada foorarsigu waxay u socotaa kor u kaca, si wax ku ool ah u dhamaystiraya leexinta dabada guddida koowaad iyo madaxa guddiga labaad si hufan.

Nooca Kale

Haddii aad xiiseyso safafyada shafka ah oo ay ka muuqdaan laba laab oo dhinaca ballaadhan ah, si fudud u dhufo sawirka si aad u qoto dheer ugu sii gasho habka wax soo saarka ee faahfaahsan oo aad daawato fiidyaha la socda.

Farqiga muhiimka ah:

Nooca laba-laaban ayaa bixiya adkeysiga la xoojiyey marka la barbar dhigo nooca hal-laab, hubinta isticmaalka dheeraadka ah. Si kastaba ha ahaatee, nooca hal-laaban ayaa si ku filan u buuxiya shuruudaha kaydinta. Intaa waxaa dheer, cidhifyada nooca laba-laabantu maaha kuwo fiiqan, kor u qaadaya badbaadada inta lagu jiro isticmaalka, halka nooca hal-laaban uu yeelan karo geeso fiiqan.

1. Decoiler

2. Quudinta

3. Feer

4. Gawaarida samaynta duubka

5. Habka wadista baabuurta

6. Habka goynta

Kuwo kale

Miiska bannaanka