yees duab

Profile

Cov kab ntau lawm no tuaj yeem tsim ntau qhov sib txawv ntawm C-hom, Z-hom, thiab M-hom purlins nrog rau qib siab ntawm automation. Nws yog kev xaiv kev nqis peev uas raug nqi.

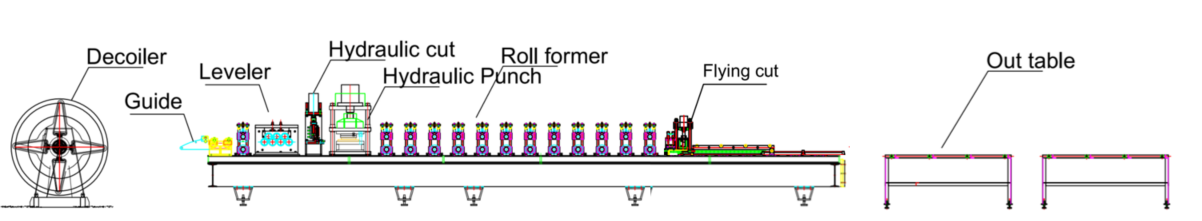

Flow daim ntawv qhia

Decoiler

Peb nruab anias-armntawm lub decoiler tuav cov hlau kauj nyob rau hauv qhov chaw thaum hloov coils, tiv thaiv kev tso tawm sai sai thiab muaj peev xwm tsim kev puas tsuaj rau cov neeg ua haujlwm. Ntxiv thiab,steel tiv thaiv nploojyog ntsia los tiv thaiv coil slippage thaum uncoiling. Qhov kev tsim no tsis tsuas yog tiv thaiv cov hlau kauj thiab lub tshuab, tab sis kujua kom muaj kev nyab xeeb.

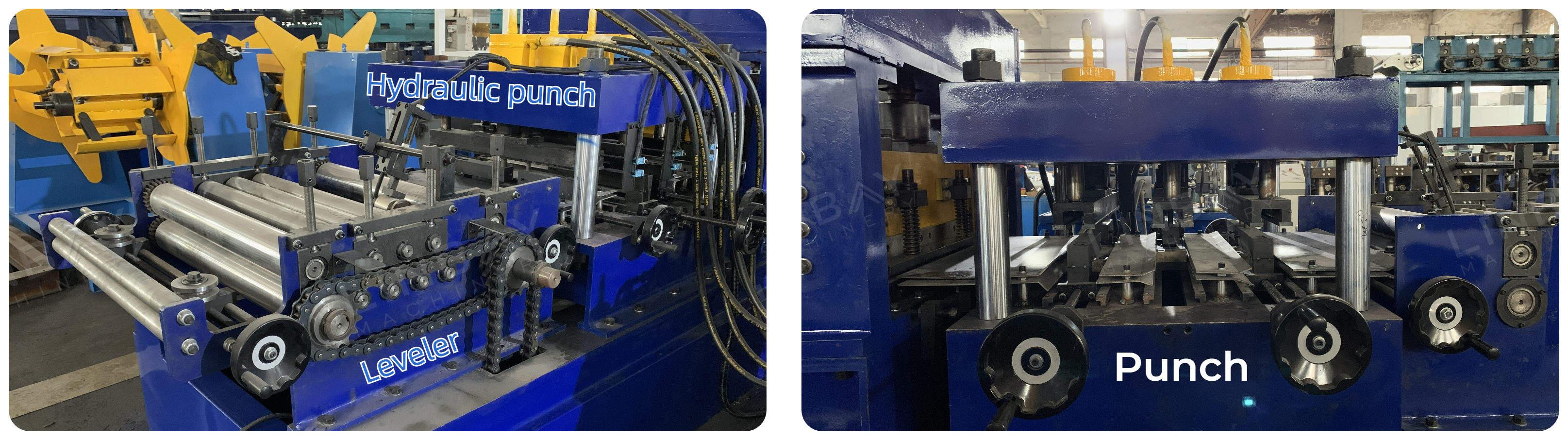

Qhia & Qib

Kev taw qhia chais kom cov hlau kauj thiab cov cav tov ntawm tib qhov chaw-kab mus rautiv thaiv distortionntawm cov tsim profiles. Ntau cov kev taw qhia rollers tau muab tso rau hauv cov kab ntau lawm. Thiab tom qab ntawd, cov hlau kauj nkag mus rau qib qib, uastshem tawm tej irregularities, txhim khu lub flatness thiab parallelismntawm steel coil. Qhov no, nyob rau hauv lem,txhim kho qhov zoontawm ob lub kauj thiab cov khoom kawg purlin.

Hydraulic punch

Lub tshuab xuas nrig ntaus hydraulic tuaj nrogpeb teev tuagthiab coj cov roj thooj voos kheej kheej. Cov tuag no tuaj yeem ua tausai thiab yooj yimkho kom tau raws li cov neeg siv khoom specifications, muabzoo heev yooj. Cov txheej txheem tuag hloov pauv tau zoo thiab feem ntau ua tiav hauv5 feeb.

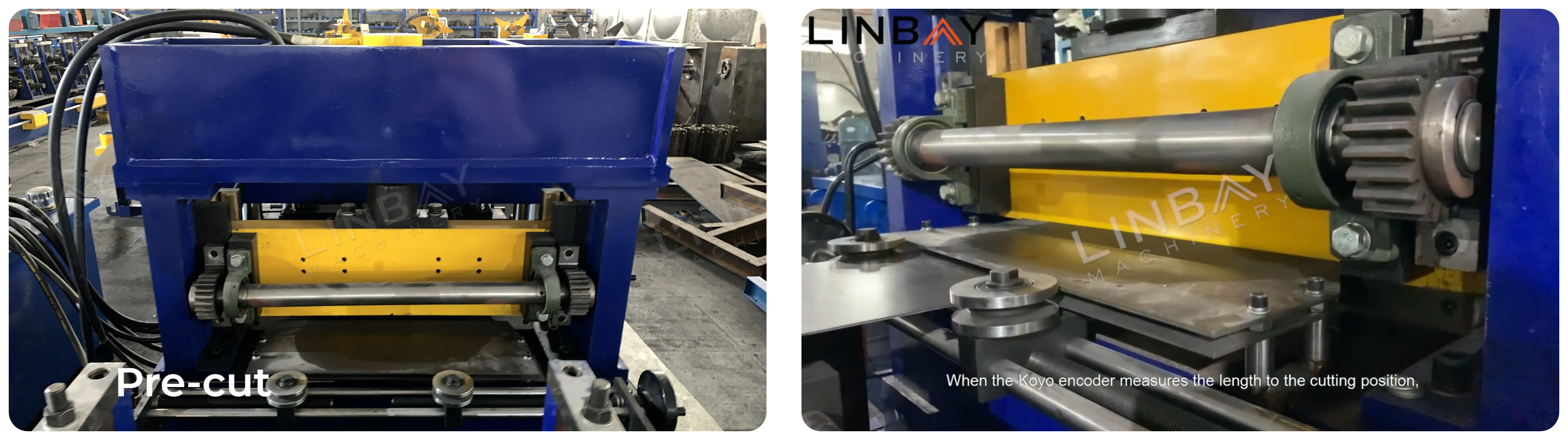

Pre txiav

Txhawm rau kom yooj yim hloov pauv ntawm qhov sib txawv coil dav rau kev tsim ntau qhov ntau thiab tsawg thiab txuag cov khoom siv raw, cov cuab yeej ua ntej txiav yog tsim los rau kev ua haujlwm zoo,txo cov khoom pov tseg.

Leveler, xuas nrig ntaus tshuab thiab txiav tshuab yog ua ke nrog yob txoj kev tshuab, uas yog heevtus nqi tsim nyog.

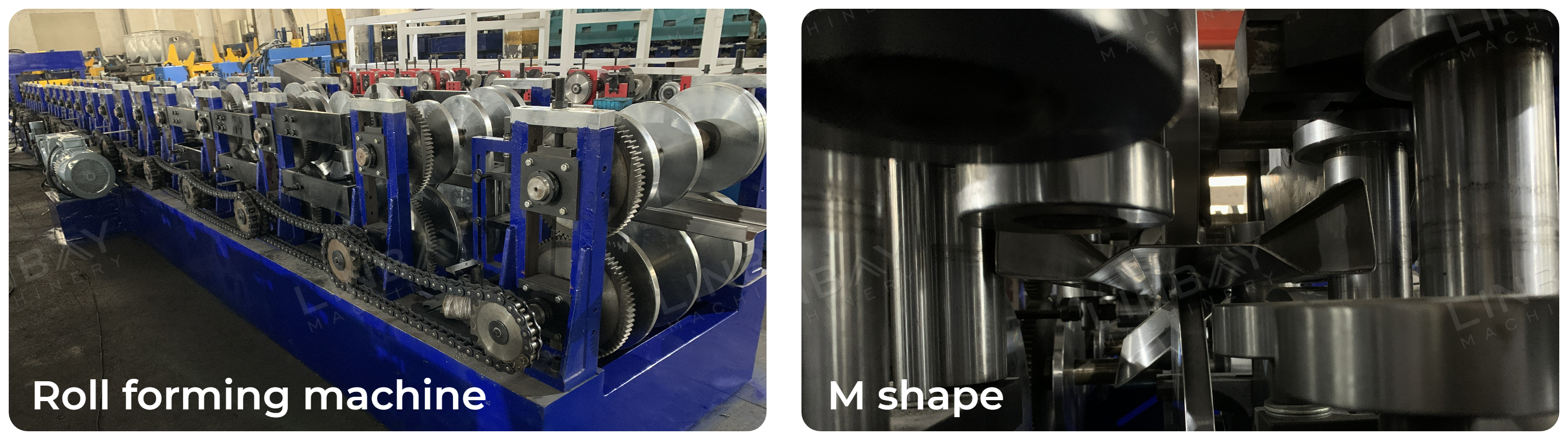

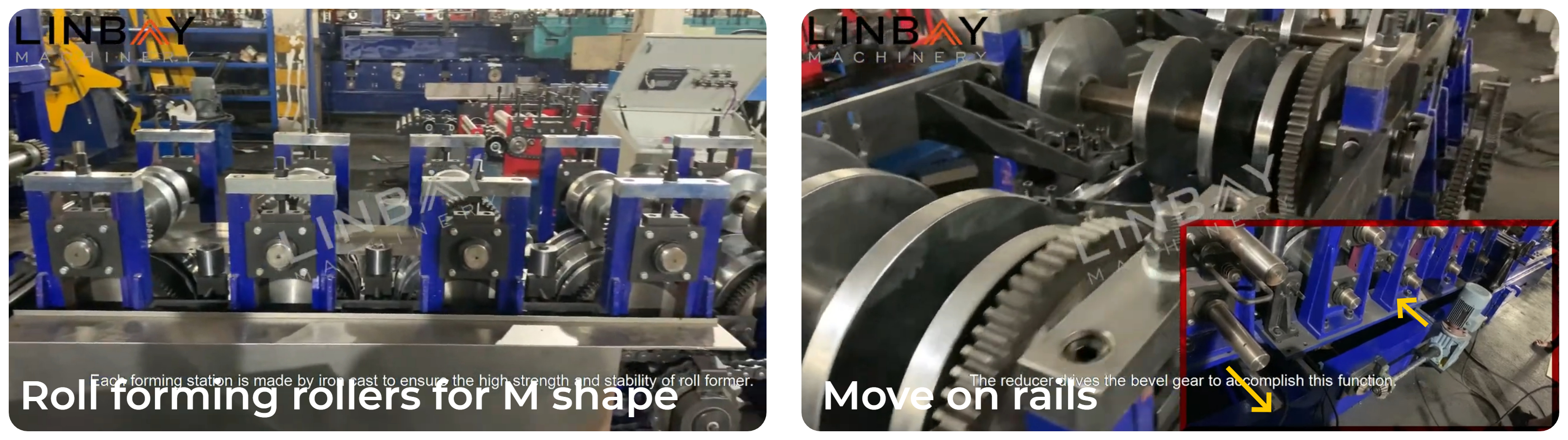

Roll qub

Roll forming tshuab nta acam khwb cia-hlau qauvthiabchain tsav system. Cov qauv cam khwb cia hlau yogib daim hlau, ua kom ruaj khov thiab ruaj khov. Lub tshuab no muaj peev xwm ua tauC, Z, thiab Sigma purlins. Thawj plaub lub rollers yog siv rau cov duab Sigma, thiab lawv tau tsa thaum tsim C lossis Z duab. Tsis tas li ntawd, manually tig2-3 qhov chaw tsim khoom los ntawm 180 °, koj tuaj yeem hloov ntawm kev tsim C thiab Z purlins. Cov chaw tsim khoom ntawm ib sab ntawm lub tshuab txav ntawm cov ntsia hlau los tsim cov purlins ntawmtxawv qhov dav. Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias, raws li kev thov, peb tuaj yeem tsim cov tshuab purlin uas sib txawvob qhov siab thiab hauv qab davib txhij.

Chaw nres tsheb Hydraulic

Peb qhov chaw nres tsheb hydraulic yog nruab nrog lub kiv cua txias uas pab tswj kev ua haujlwm kom zoo, ua kom ntseeg taunce efficiencythaum ua haujlwm tas mus li.

Encoder & PLC

Cov neeg ua haujlwm tuaj yeem tswj lub tshuab los ntawm PLC npo, kho cov khoom tsim tawm speed, teeb tsa qhov ntev, thiab txiav qhov ntev, thiab lwm yam. Ib qho encoder yog kev koom ua ke rau hauv cov kab ntau lawm, hloov qhov ntev ntawm steel coil mus rau hauv cov teeb liab hluav taws xob relayed rau PLC tswj vaj huam sib luag. Qhov no tso cai rau peb lub tshuab ua haujlwmtxiav precision hauv 1 hli, guaranteeing cov khoom zoo thiabtxo cov khoom pov tsegvim txiav yuam kev.

Peb muab cov kev pabcuam customization, suav nrog tab sis tsis txwv rau cov qauv tsav, hom, hom khoom siv hluav taws xob, thiab PLC tswj vaj huam sib luag lus.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj