Kev piav qhia

Linbay Machinery yog tus kws tshaj lij ntawmctau tais yob txoj kev tshuabthiabcable ladder yob txoj kev tshuabtsim tawm. Peb tau tsim ntau yam sib txawvcable tais thiab cable ladder yob txoj kev tshuab. Ntawm no koj yuav paub cov ntsiab lus ntawm cable ladder yob txoj kev tshuab.

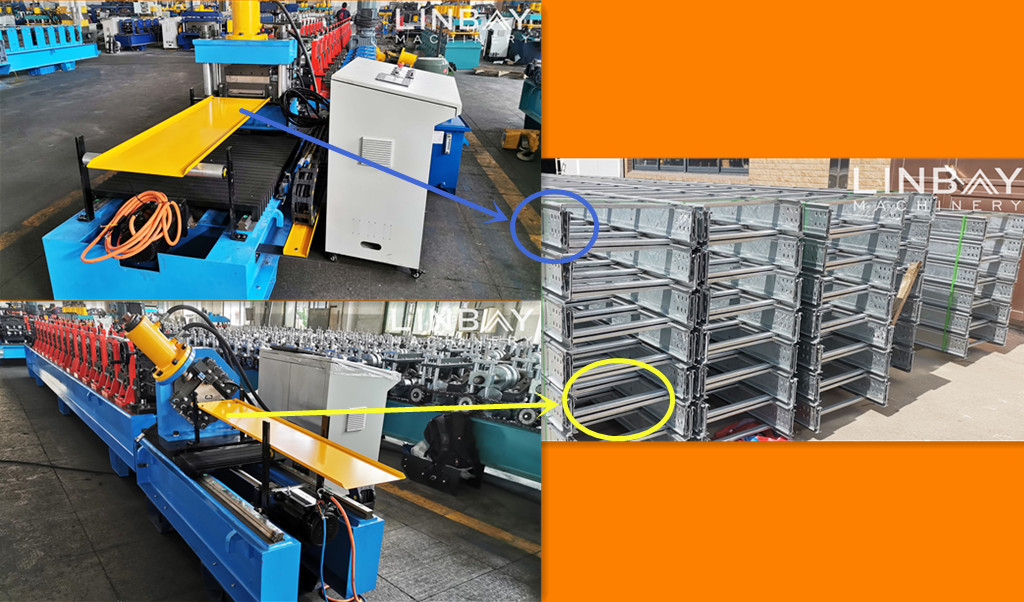

Ib txwm cable ntaiv muaj ob ntu: sab phab ntsa thiab ntaiv rung, thaum koj muaj ob qhov no ua los ntawm yob txoj kev tshuab, koj xav tau lub tshuab vuam los ua kom lawv ua ke. Qhov dav ntawm tus ntaiv cable yog qhov ntev ntawm qhov ntev thiab qhov ntev ntawm tus ntaiv yog qhov ntev ntawm sab phab ntsa. Yog li cable ntaiv tsis xav tau ntau ntawm kev nqis peev, tsuas yog ob lub yob txoj kev tshuab, ib qho rau cable ladder thiab ib qho rau tus ntaiv rung, ces ib tug tsis siv neeg los yog phau ntawv welder. Nws yog ntau pheej yig dua cable tais yob txoj kev tshuab. Thiab dhau li ntawd, peb kuj tau ua ob chav kab tshuab, uas ib kab los tsim cov ntaiv rung thiab sab phab ntsa ob profiles, tab sis ib zaug tsuas yog tsim ib qho profile, tab sis tshuab nqi qis dua ob lub yob txoj kev tshuab. Tab sis koj tuaj yeem pom, nws xav tau ntau ntawm phau ntawv txheej txheem thaum lub sijhawm tsim khoom, nws muaj peev xwm tsim tau tsawg.

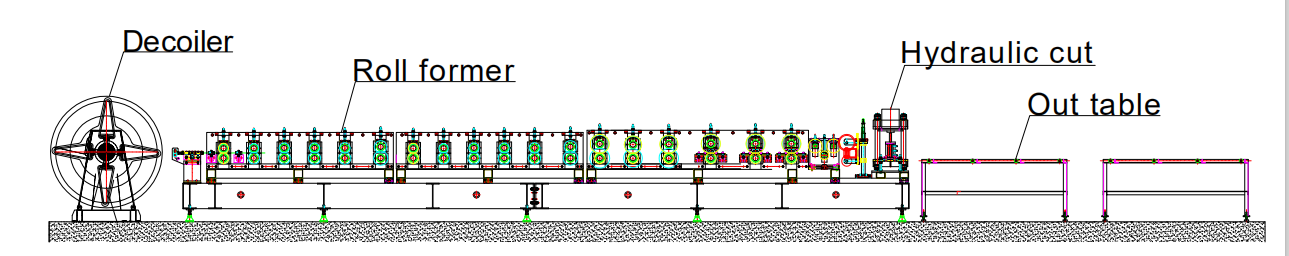

Flow daim ntawv qhia:

Decoiler--Yav dhau los--Flyting txiav--Out rooj

Txhawm rau daws qhov teeb meem no, Linbay Machinery tau ua haujlwm nrog peb cov neeg siv khoom suav los tsim ib qhotshiab hom cable ntaiv yob txoj kev tshuab. Cov profile muaj lub peev xwm thauj khoom zoo, cov duab zoo nkauj thiab tib lub sijhawm nws tso cai rau tsim cov kab ntau lawm thiab tsis muaj kev cuam tshuam. Lub thickness ntawm hom tshiab no yog 1.8mm. Nws tuaj yeem tiv taus av qeeg 8-chav kawm thiab tsim nyog rau thaj tsam av qeeg hauv lub tebchaws thiab cov phiaj xwm nuclear, cov qauv tau lees paub los ntawm lub chaw kuaj kev tshaj lij. Linbay yog thawj thiab tshwj xeeb chaw tsim tshuaj paus ntawm no cable ladder yob txoj kev tshuab. Hom tshiab cable ladder tsim los ntawm LINBAY tsuas yog yuav tsum tau yuav ib lub yob txoj kev tshuab kom paub txog cov khoom siv tsis siv neeg. Lub perforation ntawm no cable ladder yog ntau nyuaj, lub rung kuj nrog kab rov tav embossment yog li txhua qhov dav qhov ntev yuav tsum tau cais cov pwm pwm, yog li tus nqi ntawm cov pwm yog qhov siab. Yog hais tias nws yog tsim los ntawm ib tug punching xovxwm, peb yuav tsum tau siv ib tug gantry-hom 500-tuj punch xovxwm. Xav txog tus nqi, peb siv hydraulic xuas nrig ntaus cov chaw nres tsheb, uas yog kev lag luam ntau dua, tab sis qhov ntau lawm yuav qeeb qeeb. Qhov ceev ntawm kab no yog nyob ib ncig ntawm 3-4 meters ib feeb. Yog tias peb siv gantry-hom 500-tuj punch xovxwm, nws xuas nrig ntaus 30 zaug hauv ib feeb nrog ib kauj ruam deb ntawm 300mm, thiab qhov ceev ceev tuaj yeem ncav cuag 9 meters ib feeb.

Daim duab profile no yog qhov nyuaj dua, thiab nws xav tau 25 txheej txheem tsim tom qab xuas nrig ntaus. Vim tias daim ntawv yog thicker, peb siv cam khwb cia hlau sawv nrog tsis siv neeg kab rov tav txav. Cov kab ntau lawm no siv tom qab txiav thiab tsis muaj khib nyiab guillotine kom txuag tau cov ntaub ntawv raw. Txhua qhov loj muaj nws cov hniav. Qhov zoo ntawm kev txiav tom qab txiav yog qhov zoo nkauj dua. Tam sim no, hom tshiab cable ntaiv no kuj tsis tshua muaj nyob hauv khw, thiab muaj tus nqi kom zoo dua. Ua tau dhau los ntawm cov ntaiv cable, cov kab ntau lawm no kuj tuaj yeem tsim cov tais cable nrog tib qhov profile los ntawm kev hloov cov pwm pwm, nws yog cov kab ntau lawm thiab yog qhov kev xaiv zoo peev.

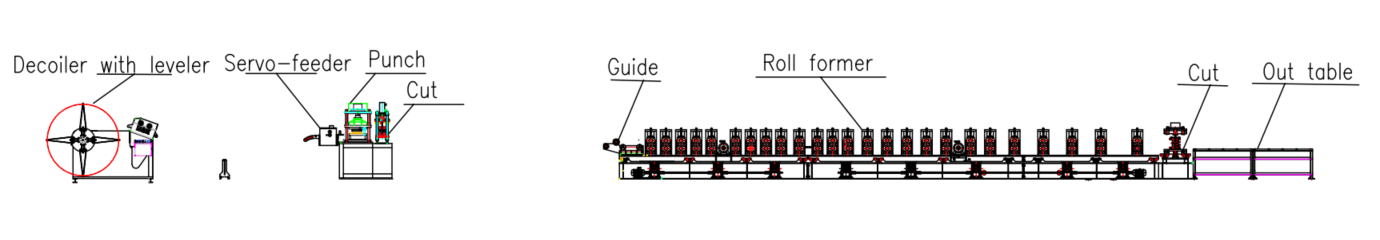

Flow daim ntawv qhia:

Decoiler nrog qib--Servo feeder--Hydraulic punch--Hydraulic ua ntej-txiav--Yob qub--Hydraulic txiav-- Tawm rooj

Tag nrho cov txheej txheem ntawm Cable Ladder Roll Forming Tshuab

Technical Specifications

| Tsis Siv Neeg Cable Tais Yob txoj Tshuab | ||

| Machinable Khoom: | A) Galvanized hlau | Thickness (MM): 0.6-1.2, 1-2 |

| B) PIB | ||

| C) carbon steel | ||

| Yield zog: | 250-550 Mpa | |

| Tensil stress: | G250 Mpa-G550 Mpa | |

| Decoiler: | Phau ntawv decoiler | * Hydraulic decoiler (yeem) |

| Punching system: | Hydraulic punching chaw nres tsheb | * Punching xovxwm (yeem) |

| Tsim chaw nres tsheb: | Raws li koj qhov profile drawings | |

| Main tshuab lub cev muaj zog hom: | Shanghai Dedong (Sino-Germany Hom) | * Siemens (yeem) |

| Tsav system: | Chain tsav | * Gearbox tsav (Yeem) |

| Tshuab qauv: | Hom Cantilever | * Forged Hlau chaw nres tsheb (Yeem) |

| Kev sib sau ceev: | 10-20 (M / min) | * Los yog raws li koj cov duab kos duab |

| Rollers cov khoom siv: | GCr 15 | * SKD-11 (Yeem) |

| Txiav qhov system: | Tom qab txiav | * Pre-txiav (yeem) |

| Frequency changer hom: | Yaskawa | * Siemens (yeem) |

| PLC hom: | Panasonic | * Siemens (yeem) |

| Fais fab mov: | 380V 50Hz 3 ph | * Los yog raws li koj xav tau |

| Tshuab xim: | Industrial xiav | * Los yog raws li koj xav tau |

LINBAY MACHINERY ua haujlwm li cas thaum COVID-19?

Lub installation ntawm yob txoj kev tshuab thaum lub sij hawm COVID-19 yog dawb!

Ntawm no LINBAY yuav piav qhia yuav ua li cas peb ua lub installation ntawm peb yob txoj kev tshuab.

Ua ntej, peb kho lub tshuab hauv peb cov nroj tsuag, peb yuav nug seb qhov luaj li cas koj yuav tsim ua ntej, peb muab lub tshuab rau hauv qhov loj nws yuav tsim thiab kho tag nrho cov tsis raug ua ntej xa zaub mov, yog li koj tsis tas yuav hloov dab tsi thaum koj tau txais lub tshuab no.

Thib ob thaum peb disassemble lub tshuab rau debug, peb muab cov yeeb yaj duab kom koj paub yuav ua li cas txuas lawv. Txhua lub tshuab muaj nws cov yeeb yaj kiab. Hauv daim vis dis aus, nws yuav qhia yuav ua li cas txuas cov cables thiab cov raj, muab cov roj, muab tso ua ke ntawm lub cev thiab lwm yam ...

Ntawm no yog ib qho piv txwv ntawm qhov video: https://youtu.be/p4EdBkqgPVo

Thib peb, thaum koj tau txais cov khoom siv, koj yuav muaj ib pab pawg wahtsapp lossis wechat, peb tus engineer (Nws hais lus Askiv thiab Lavxias) thiab kuv (Kuv hais lus Askiv thiab lus Mev) yuav nyob hauv pab pawg los txhawb koj yam tsis ntseeg.

Plaub, peb xa koj phau ntawv qhia ua lus Askiv lossis lus Mev kom koj nkag siab txhua lub ntsiab lus ntawm cov nyees khawm thiab yuav pib lub tshuab li cas.

Peb muaj ib rooj plaub uas kuv cov neeg tuaj ntawm Nyab Laj tau txais nws lub tshuab thaum lub Kaum Ib Hlis 25, thiab muab tso rau hauv hom thaum hmo ntuj, thiab pib tsim tawm rau lub Kaum Ib Hlis 26. Thiab ntxiv rau qhov no, peb tau ua tiav ntau qhov kev ua tiav hauv kev txhim kho cov tshuab nyuaj. Tsis muaj teeb meem nrog lub installation ntawm koj lub tshuab. LINBAY muab qhov zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws rau peb cov neeg siv khoom, tshwj xeeb hauv qhov xwm txheej no. Koj tsis tas yuav tos kom txog thaum COVID hla. Koj tuaj yeem tsim cov profiles tam sim ntawd nrog peb cov tshuab.

Q&A

1. Q: Koj muaj kev paub dab tsi hauv kev tsim khoomcable ladder yob txoj kev tshuab?

A: Peb tau xa tawm cable tais ntau lawm kab rau Russia, Australia, Argentina, Malaysia, Indonesia. Peb tau tsimperforated cable tais, CT cable tais, ntaiv cable taisthiab lwm yam Peb ntseeg siab los daws koj cov teeb meem cable tais.

2. Q: Kuv puas tuaj yeem siv ib kab los tsimladder cable tais thiab tais npog?

A: Yog, koj twv yuav raug hu siv ib txoj kab los tsim cov tais cable thiab lub tais npog. Kev hloov pauv yog yooj yim, koj tuaj yeem ua tiav hauv ib nrab teev. Ua li no, qhov no yuav txo koj cov nqi thiab sijhawm zoo heev.

3. Q: Lub sijhawm khoom xa tuaj yog dab tsintaiv cable tais tshuab?

A: 120 hnub rau 150 hnub nyob ntawm koj daim duab.

4. Q: Koj lub tshuab ceev yog dab tsi?

A: Lub tshuab ua haujlwm ceev nyob ntawm kev kos duab tshwj xeeb xuas nrig ntaus. Nquag sib sau ceev yog nyob ib ncig ntawm 20m / min. Thov xa koj daim duab rau peb thiab qhia rau peb paub koj qhov kev xav tau ceev, peb yuav kho nws rau koj.

5. Q: Koj tuaj yeem tswj koj lub tshuab precision thiab zoo li cas?

A: Peb tsis pub leejtwg paub los ua qhov tseeb yog tias peb lub Hoobkas muaj nws tus kheej cov kab ntau lawm, los ntawm kev xuas nrig ntaus pwm mus rau kev ua cov menyuam, txhua qhov khoom siv ua tiav ntawm nws tus kheej los ntawm peb lub Hoobkas tus kheej. Peb nruj me ntsis tswj qhov raug ntawm txhua kauj ruam los ntawm kev tsim, ua, sib dhos rau kev tswj kom zoo, peb tsis kam txiav cov fab.

6. Q: Koj qhov kev pab cuam tom qab muag yog dab tsi?

A: Peb tsis txhob yig muab lub sijhawm lav rau koj ob xyoos rau tag nrho cov kab, tsib xyoos rau lub cev muaj zog: Yog tias yuav muaj teeb meem zoo los ntawm cov khoom tsis yog tib neeg, peb yuav daws nws tam sim ntawd rau koj thiab peb yuav npaj rau koj 7X24H. Ib qho kev yuav khoom, kev saib xyuas lub neej rau koj.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj