Kev piav qhia

CovStud thiab Track Roll Forming Tshuab, raws li lub npe hu uaHat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Yob txoj Tshuab, Phab Ntsa Rolls Tshuab, Qab nthab Roll Tshuab Lub Teeb Steel Keel Roll Tshuabthiab lwm yam tuaj yeem tsim cov studs, lem thiab ntau lwm cov duab los ntawm daim duab C.

Lub thickness feem ntau tuaj yeem tsim ntawm 0.25-1.2mm.

Yog tias koj xav tau kev ua haujlwm ntau dua ces peb xav kom koj adpot Flying shear nrog Tsis-stop system .

Qhov Max. tag nrho cov kab ceev tuaj yeem ncav cuag 40m / min.

Yog tias koj xav tsim ntau tshaj ib qho profile hauv ib lub tshuab, peb pom zoo rau koj ob kab sib sau tshuab thiab triple kab sib sau tshuab kom txuag chaw thiab kev lag luam.

Technical Specifications

| Stud, Track thiab Channel Roll Forming Machine | |||

| Tsis muaj. | Yam khoom | Specification | xaiv tau |

| 1 | Cov khoom tsim nyog | Hom: Galvanized Coil, PPGI, Carbon Steel Chev | |

| Thickness (hli): 0.25-1.2 | |||

| Yield zog: 250-550MPa | |||

| Tensil stress (Mpa): G350Mpa-G550Mpa | |||

| 2 | Nominal sib sau ceev (m / min) | 10-40 | Los yog raws li koj xav tau |

| 3 | Tsim chaw nres tsheb | 8–14 | |

| 4 | Decoiler | Phau ntawv decoiler | Hydraulic decoiler los yog ob lub taub hau decoiler |

| 5 | Main tshuab lub cev muaj zog | Sino-German Brand | Siemens |

| 6 | PLC hom | Panasonic | Siemens |

| 7 | Inverter hom | Yaskawa | |

| 8 | Tsav tsheb | Chain tsav | Gearbox tsav |

| 9 | Rollers'khoom | Steel #45 | GCr15 |

| 10 | Chaw nres tsheb qauv | Phab ntsa vaj huam sib luag chaw nres tsheb | Forged Hlau chaw nres tsheb lossis torri sawv ntsug qauv |

| 11 | Punching system | No | Hydraulic punching chaw nres tsheb lossis Punching xovxwm |

| 12 | Txiav qhov system | Tom qab txiav | Pre-txiav |

| 13 | Lub zog xav tau | 380V 60Hz | Los yog raws li koj xav tau |

| 14 | Tshuab xim | Industrial xiav | Los yog raws li koj xav tau |

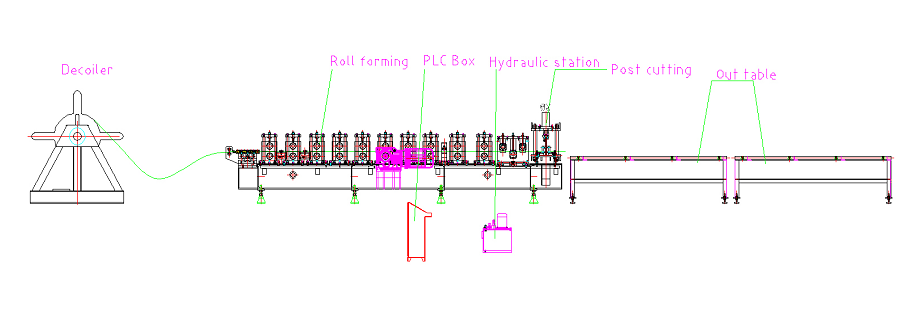

Flow Chart

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj