Kev piav qhia

Roll forming tshuabmuaj ntau daim ntawv thov, Linbay Machinery tau uayob txoj kev tshuab rau hlau laj kab ncej. Linbayyob txoj kev tshuabtuaj yeem uahlau mesh laj kab ncej,hlau laj kab ncej rau ntoo laj kab.Hlau mesh laj kab ncejnquag sivpeach yam profile, thickness yog 1-1.2mm, txias dov los yog kub dov hlau, galvanized steel,Peach ncej nkhaus laj kabyog dav siv nyob rau hauv txoj kev loj, railway, tshav dav hlau, lub nroog txoj kev, grand square thiab paj thiab nyom laj kab thiab lwm yam. Nws tsis tsuas yog tiv thaiv kev nyab xeeb ntawm tsheb thiab neeg taug kev, tab sis kuj beautifies qhov chaw ib puag ncig. Covhlau ncejrauntoo laj kab systemtuaj yeem nyob rau ntau xyoo uas tso cai rau kev zoo nkauj ntawm cov ntoo kom tseem ceeb, thaum muab lub zog zoo ntawm cov hlau. Nrov thickness yog 3 hli.

LINBAYyob txoj kev tshuabtuaj yeem ua ntau tus ncej profile,guardrail ncej,Hnub ci photovoltaic stents,vineyard postlwm.

Daim ntawv thov

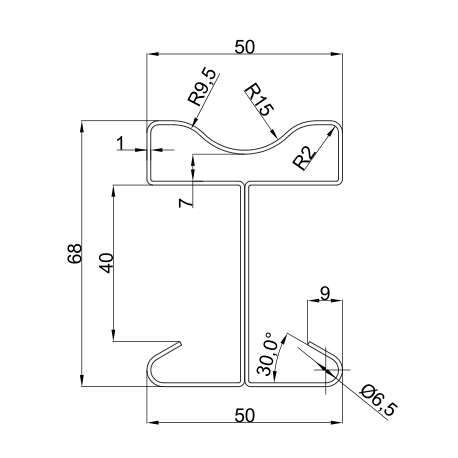

3D-Drawing

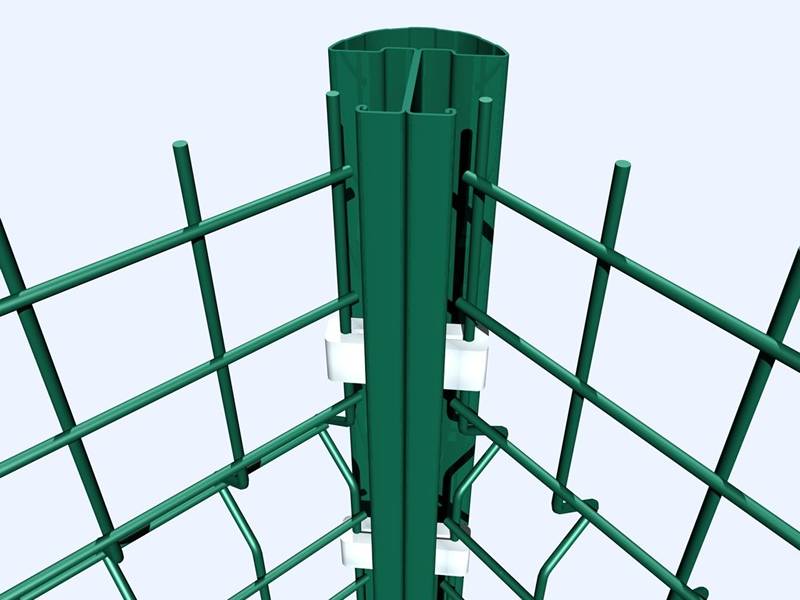

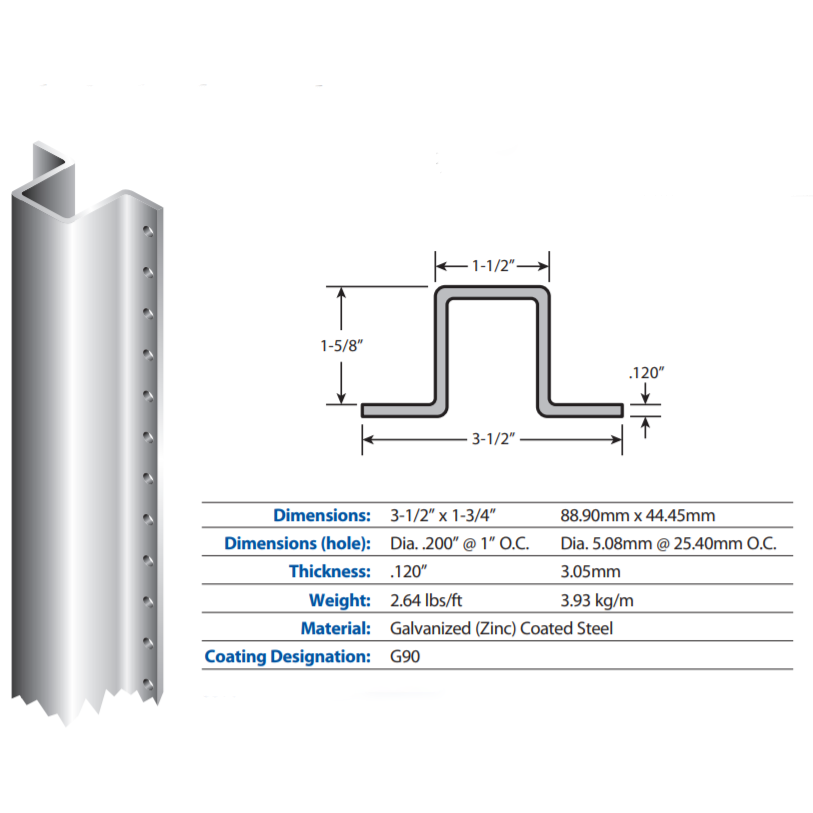

Hlau Mesh Fence Post

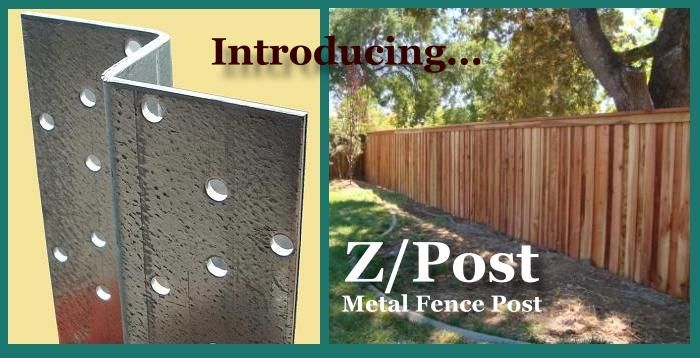

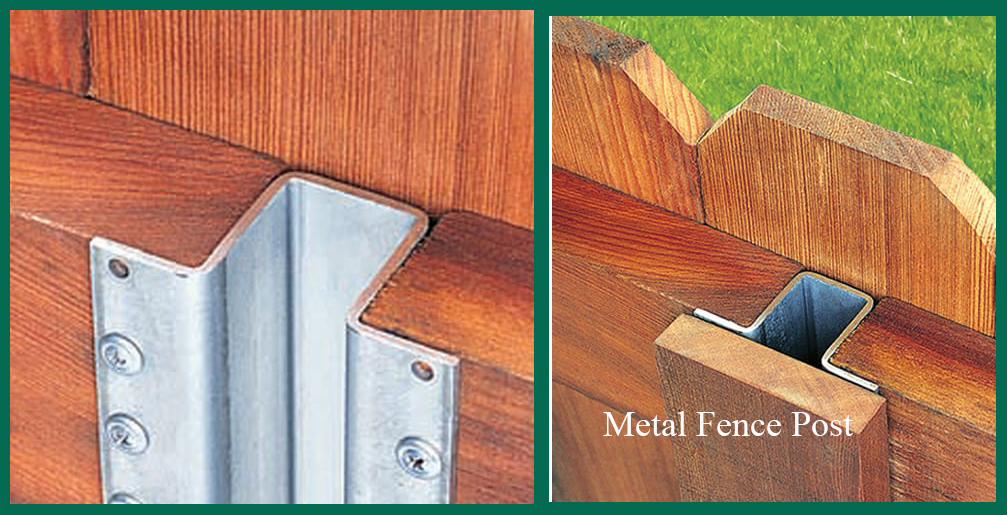

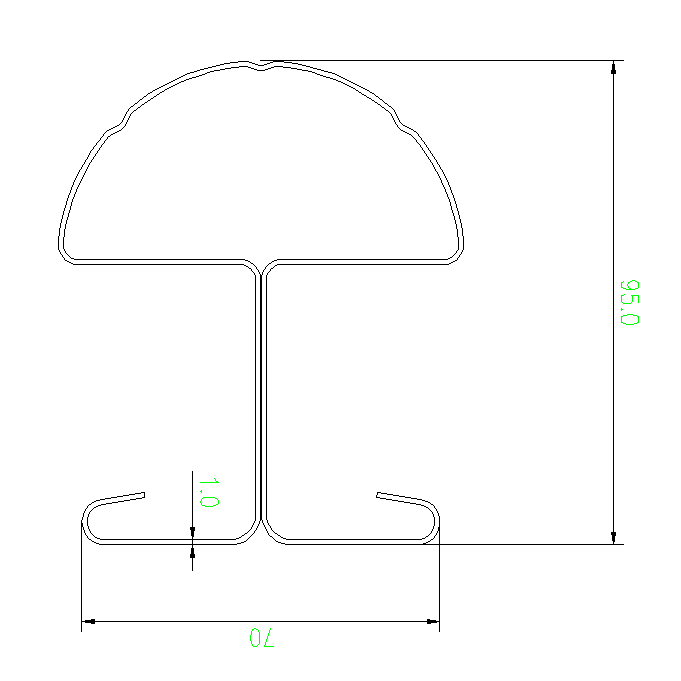

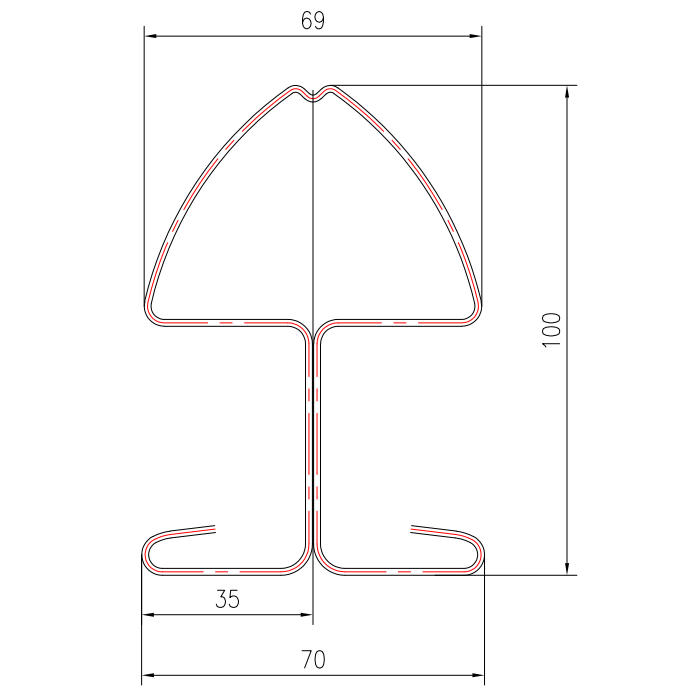

Z Post / Hlau laj kab ncej rau ntoo fencing system

Hlau laj kab ncej rau ntoo fencing system

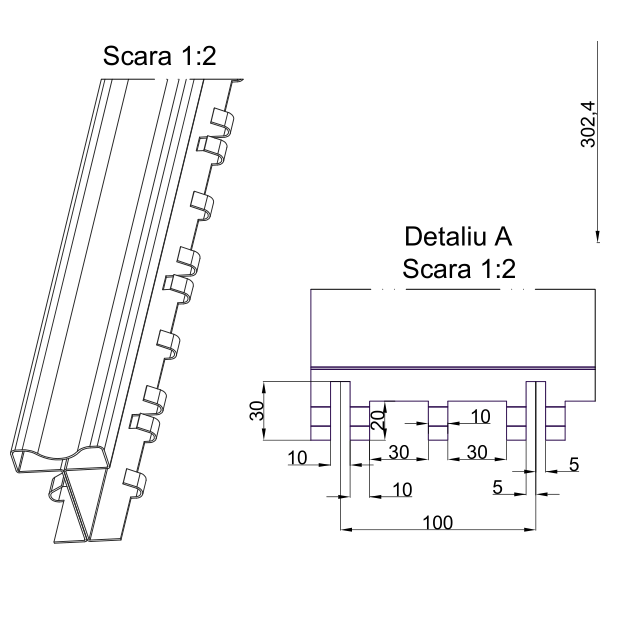

CAD daim duab

Hlau Mesh laj kab Post-India

Hlau Mesh laj kab Post-Algeria

Hlau Mesh laj kab Post-Russia

Hlau laj kab Post

Z Post / Hlau laj kab ncej

Case tiag A

Taw qhia A:

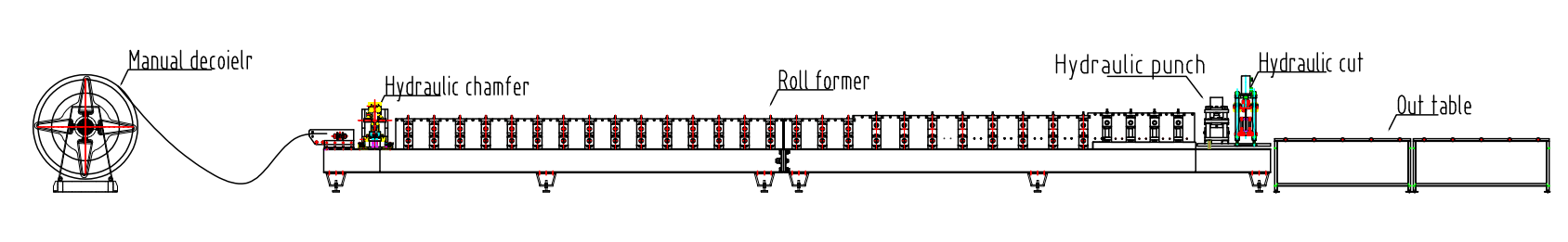

Qhov nohlau mesh laj kab ncej yob txoj kev tshuabmuaj ib tug yooj yim configuration:phau ntawv decoiler-hydraulic chamfer-yob qub-hydraulic punch-hydraulic ncej txiav-tawm rooj. Ntawm qhov pub mis ntawm lubyob txoj kev tshuab, peb ua cov cuab yeej chamfer, qhov no yog ib qho yooj yim rau kev txiav tom qab. Lub punch system nruab rau ntawm lubyob qub, nws tuaj yeem txo tus nqi ntawm lub tshuab nws yog kev xaiv nyiaj txiag, tab sis kev ua haujlwm ceev yuav qis, nyob ib ncig ntawm 4m / min. Cov neeg siv khoom tuaj yeem xaiv Case B lub tshuab teeb tsa yog tias koj xav tau ceev ceev yob txoj kev tshuab.

Case tiag B

Taw qhia B:

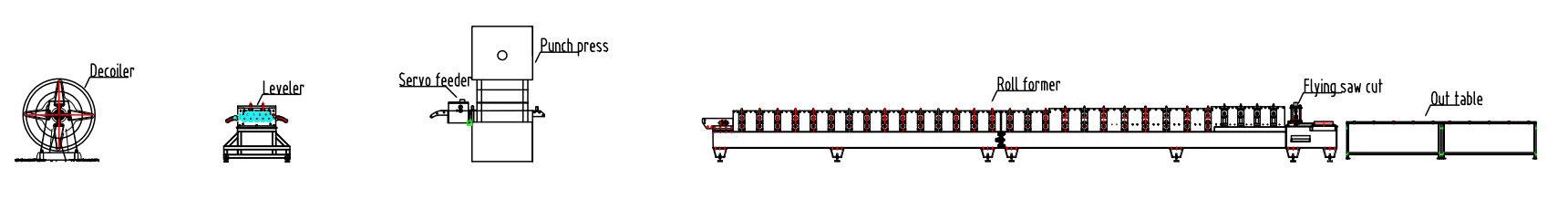

Qhov nohlau mesh laj kab ncej yob txoj kev tshuabmuaj kev kub ceev thiab precision configuration:phau ntawv decoiler- qib-servo feeder-xuas nrig ntaus- yob qub-ya saw txiav-tawm rooj. Lub servo feeder system siv Yaskawa servo lub cev muaj zog los tswj lub sijhawm pub mis rau lub punch xovxwm, ces koj yuav muaj qhov siab-precision ntawm qhov punch qhov. Lub 80Tons xovxwm tuaj yeem muab qhov nrawm nrawm piv rau hydraulic punch system, nws tuaj yeem ua ob npaug rau kev tsim khoom, mus txog 8m / min. Feem ntau peb xav kom peb cov neeg muas zaub yuav Yangli hom xovxwm JH21-80. Cov yob yav dhau los peb siv 26 qhov chaw tsim khoom los xyuas kom meej qhov profile prefect thiab 2 riveting rollers los ua profile ua ke. Nrog rau qhov ceev ceev no, peb muab lub flying saw cut device, uas yuav tsis nres lub yob qub thaum txiav. Lub saw txiav muaj me me burr thiab khib nyiab (nyob ib ncig ntawm 3 hli). Qhov no yog qhov zoo tshaj plaws yob txoj kev tshuab kev daws teeb meem peb xav kom xaim mesh laj kab ncej.

Linbay ua cov kev daws teeb meem sib txawv raws li cov neeg siv khoom kos duab, siab ntev thiab peev nyiaj, muab cov kev pabcuam ib-rau-ib, hloov tau rau koj txhua qhov kev xav tau. Txawm li cas los xijkoj xaiv, qhov zoo ntawm Linbay Machinery yuav xyuas kom koj tau txais kev ua haujlwm zoo kawg nkaus.

Tag nrho cov kab ntau lawm ntawm Hlau Mesh laj kab ncej Yob txoj kev tshuab

Technical Specifications

| Hlau laj kab ncej yob txoj kev tshuab | ||

| Machinable Khoom: | A) Galvanized hlau | Thickness (MM): 0.7-1.3 hli |

| B) Cov hlau dub | ||

| C) carbon steel | ||

| Yield zog: | ≤ 350 Mpa | |

| Tensil stress: | ≤ 350 Mpa | |

| Decoiler: | Phau ntawv decoiler | * Hydraulic decoiler (yeem) |

| Punching system: | Hydraulic punching chaw nres tsheb | * Punching xovxwm 80Tons (yeem) |

| Tsim chaw nres tsheb: | 26 | |

| Mian tshuab lub cev muaj zog: | 2 * 11 kWm | |

| Main tshuab lub cev muaj zog hom: | Shanghai Dedong (Sino-Germany Hom) | * Siemens Beide (yeem) |

| Tsav system: | Chain tsav | |

| Tshuab qauv: | Phab ntsa vaj huam sib luag hom | * Forged Hlau chaw nres tsheb (Yeem) |

| Ua haujlwm ceev: | 4 (M / min) | * 6-8m / min (Yeem) |

| Rollers cov khoom siv: | 45 steel | * GCr15 (yeem) |

| Txiav qhov system: | Post hydraulic txiav | * Flying saw txiav (yeem) |

| Frequency changer hom: | Yaskawa | * Siemens (yeem) |

| PLC hom: | Panasonic | * Siemens (yeem) |

| Fais fab mov: | 380V 50Hz 3ph | * Los yog raws li koj xav tau |

| Tshuab xim: | Industrial xiav | * Los yog raws li koj xav tau |

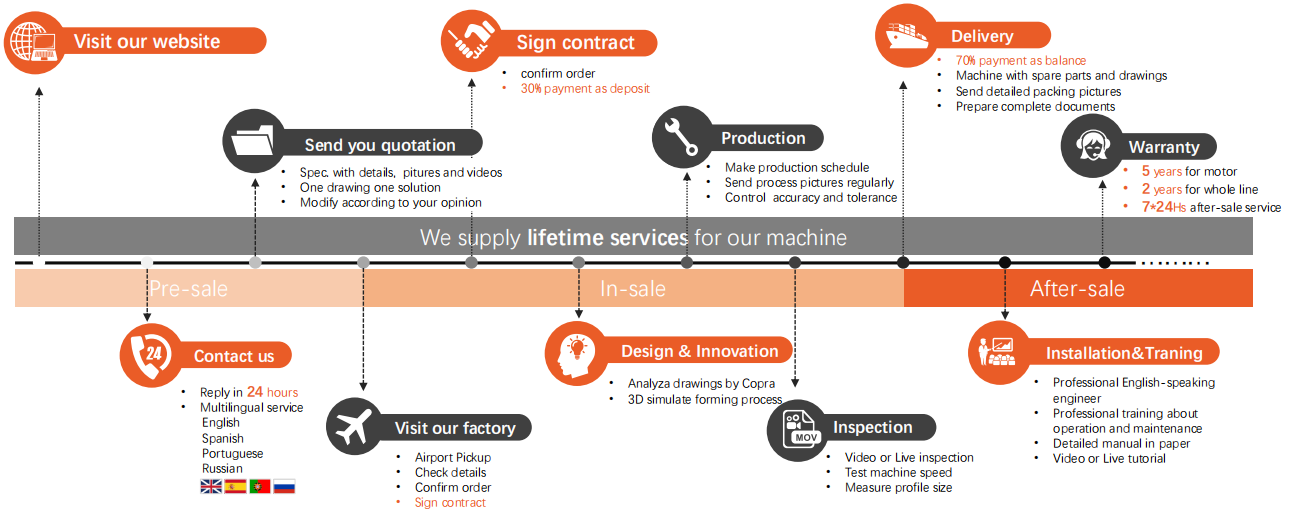

Kev yuav khoom

Q&A

1. Q: Koj muaj kev paub dab tsi hauv kev tsim khoomhlau mesh laj kab ncej yob txoj kev tshuab?

A: Peb tau exportedhlau mesh laj kab ncej ntau lawm kabmus rau Algeria, Russia thiab Indonesia. Cov laj kab hlau ncej muaj Z zoo profile, uas yog cov duab profile ntau heev, thiab peb tau xa tawm ntau txhiab tusZ profile yob txoj kev tshuab.

2. Q: Lub sijhawm khoom xa tuaj yog dab tsihlau mesh laj kab ncej yob txoj kev tshuab?

A: 60 hnub ib txwm.

3. Q: Koj lub tshuab ceev yog dab tsi?

A: Lub tshuab ua haujlwm ceev nyob ntawm kev kos duab tshwj xeeb xuas nrig ntaus. Tam sim no peb tau ua ob lub tshuab sib txawv, uas yog nrawm dua nrog punch xovxwm, nws qhov ceev yog 8m / min, thiab lwm qhov kev lag luam muaj peev xwm ceev ntawm 4m / min.

4. Q: Koj tuaj yeem tswj koj lub tshuab precision thiab zoo li cas?

A: Peb tsis pub leejtwg paub los ua qhov tseeb yog tias peb lub Hoobkas muaj nws tus kheej cov kab ntau lawm, los ntawm kev xuas nrig ntaus pwm mus rau kev ua cov menyuam, txhua qhov khoom siv ua tiav ntawm nws tus kheej los ntawm peb lub Hoobkas tus kheej. Peb nruj me ntsis tswj qhov raug ntawm txhua kauj ruam los ntawm kev tsim, ua, sib dhos rau kev tswj kom zoo, peb tsis kam txiav cov fab.

5. Q: Koj qhov kev pab cuam tom qab muag yog dab tsi?

A: Peb tsis txhob yig muab lub sijhawm lav rau koj ob xyoos rau tag nrho cov kab, tsib xyoos rau lub cev muaj zog: Yog tias yuav muaj teeb meem zoo los ntawm cov khoom tsis yog tib neeg, peb yuav daws nws tam sim ntawd rau koj thiab peb yuav npaj rau koj 7X24H. Ib qho kev yuav khoom, kev saib xyuas lub neej rau koj.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj