yees duab

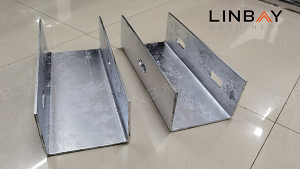

Profile

Hla bracing yog ib qho tseem ceeb rau cov khoom siv hnyav hnyav, muab kev txhawb nqa kab pheeb ces kaum ntawm ob lub uprights. Nws pab tiv thaiv wobbling thiab tswj cov qauv kev sib raug zoo nyob rau hauv hnyav loads. Feem ntau, cross bracing yog tsim los ntawm kub dov, txias dov, los yog galvanized steel nrog ib tug tuab ntawm 1.5 mus rau 2 hli.

Kev lig kev cai, cross bracing tau tsim los ntawm kev siv tshuab dabtsi yog khoov. Txawm li cas los xij, lub tshuab yob txoj kab, uas suav nrog uncoiling, leveling, yob txoj kev, xuas nrig ntaus, thiab txiav, muaj ntau dua automation thiab txo tus nqi ntawm kev ua haujlwm. Qhov kev daws teeb meem no tau dhau los ua qhov kev xaiv zoo tshaj plaws rau ntau tus neeg siv khoom vim nws qhov ua tau zoo thiab tus nqi-zoo.

Cov punching style txawv nyob ntawm tus txheej txheem installation:

Txoj Kev Txhim Kho 1: Ib txoj hlua khi ib leeg tau nruab rau hauv cov khib nyiab ncaj, yuav tsum tau ua ntej punch qhov ntawm qhov siab bracing rau ntsia hlau ntsia.

Installation Method 2: Ob lub braces yog ntsia rau hauv lub khib upright, yuav tsum tau pre-punched qhov nyob rau hauv qab ntawm lub bracing rau ntsia hlau installation.

Cov ntaub ntawv tiag-Main Techinical Parameters

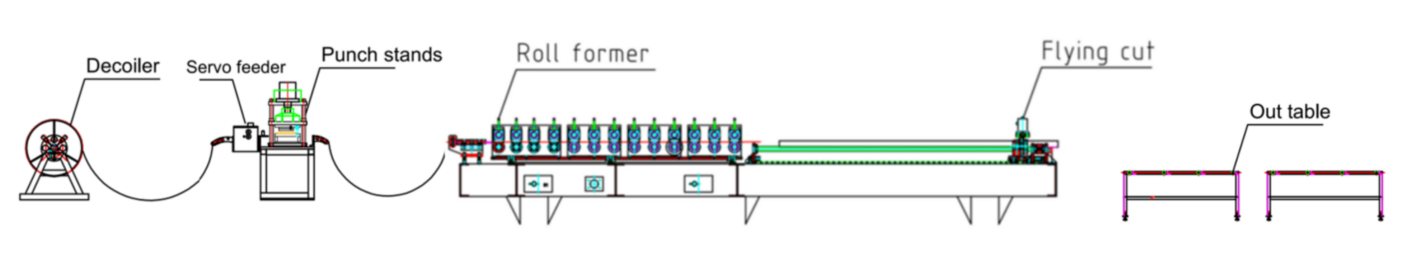

Flow daim ntawv: Decoiler--Servo feeder--Hydraulic punch--Guiding--Roll forming tshuab--Yav hydraulic txiav--Out rooj

Piv rau ob kab ntau lawm kab, ob kab ntau lawm tuaj yeem txuag koj tus nqi ntawm lub tshuab tsim ntxiv, decoiler, thiab servo feeder, nrog rau qhov chaw yuav tsum tau rau lwm cov kab ntau lawm. Tsis tas li ntawd, cov qauv ob kab txo qis lub sij hawm rau kev hloov qhov ntau thiab tsawg, tsis zoo li phau ntawv hloov pauv loj ntawm ib kab, yog li txhim kho kev ua tau zoo.

Cov ntaub ntawv tiag-Main Technical Parameters

1. Kab ceev: 4-6m / min, adjustable

2.Suitable khoom: Kub dov hlau, txias dov hlau, galvanized steel

3.Material thickness: 1.5-2mm.

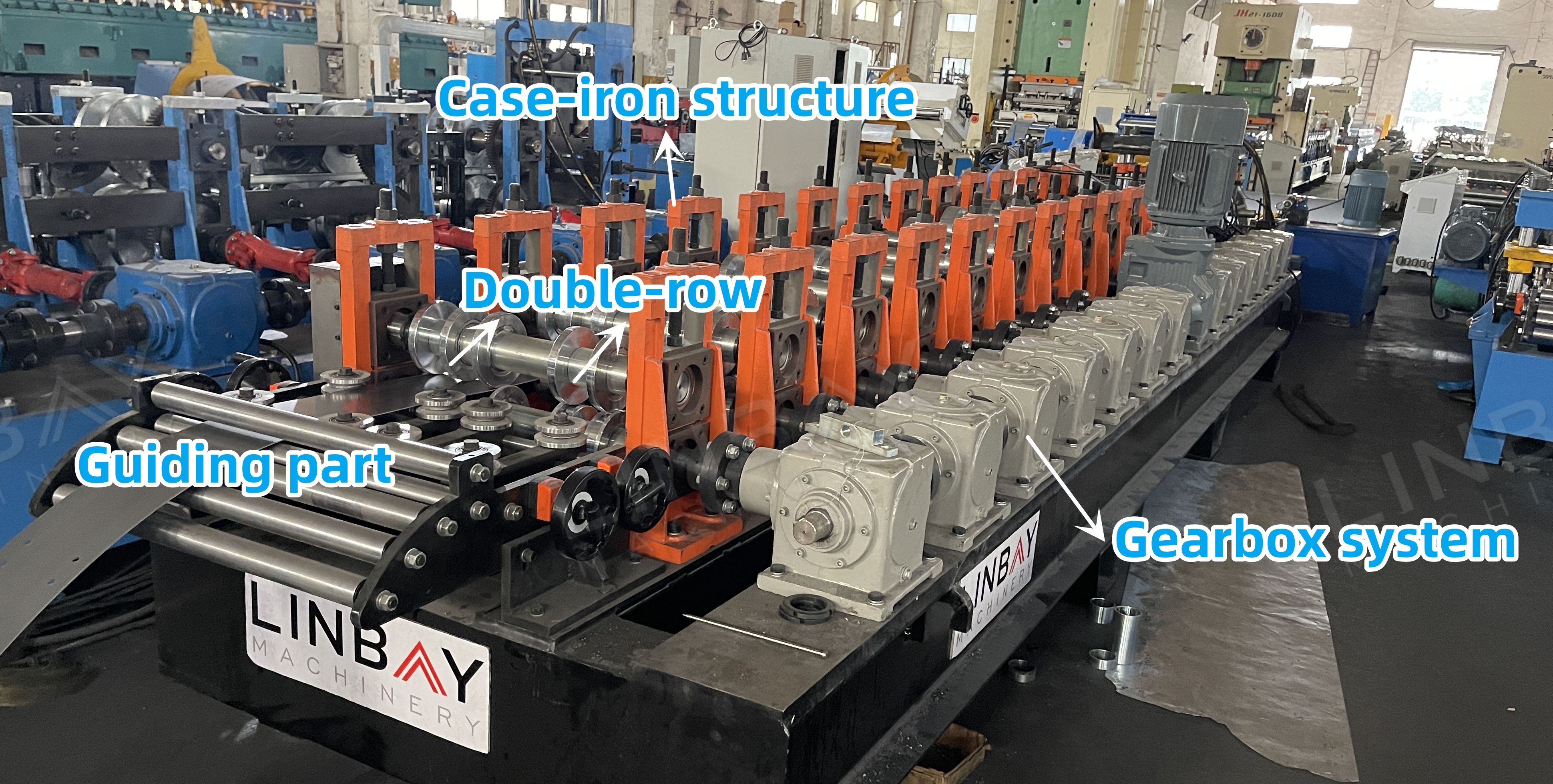

4.Roll forming tshuab: Cast-hlau qauv

5.Driving system: Gearbox tsav system

6.Cutting system: ya hydraulic txiav, lub yob qub tsis nres thaum txiav.

7.PLC txee: Siemens system.

Cov ntaub ntawv tiag-Machinery

1.Hydraulic decoiler * 1

2.Servo feeder * 1

3.Hydraulic punch tshuab * 1

4. Roll forming tshuab * 1

5.Hydraulic txiav tshuab * 1

6.Out table*2

7.PLC tswj txee * 1

8.Hydraulic chaw nres tsheb * 2

9.Cov khoom seem lub thawv (Dawb) * 1

Cov ntaub ntawv tiag tiag-Kev piav qhia

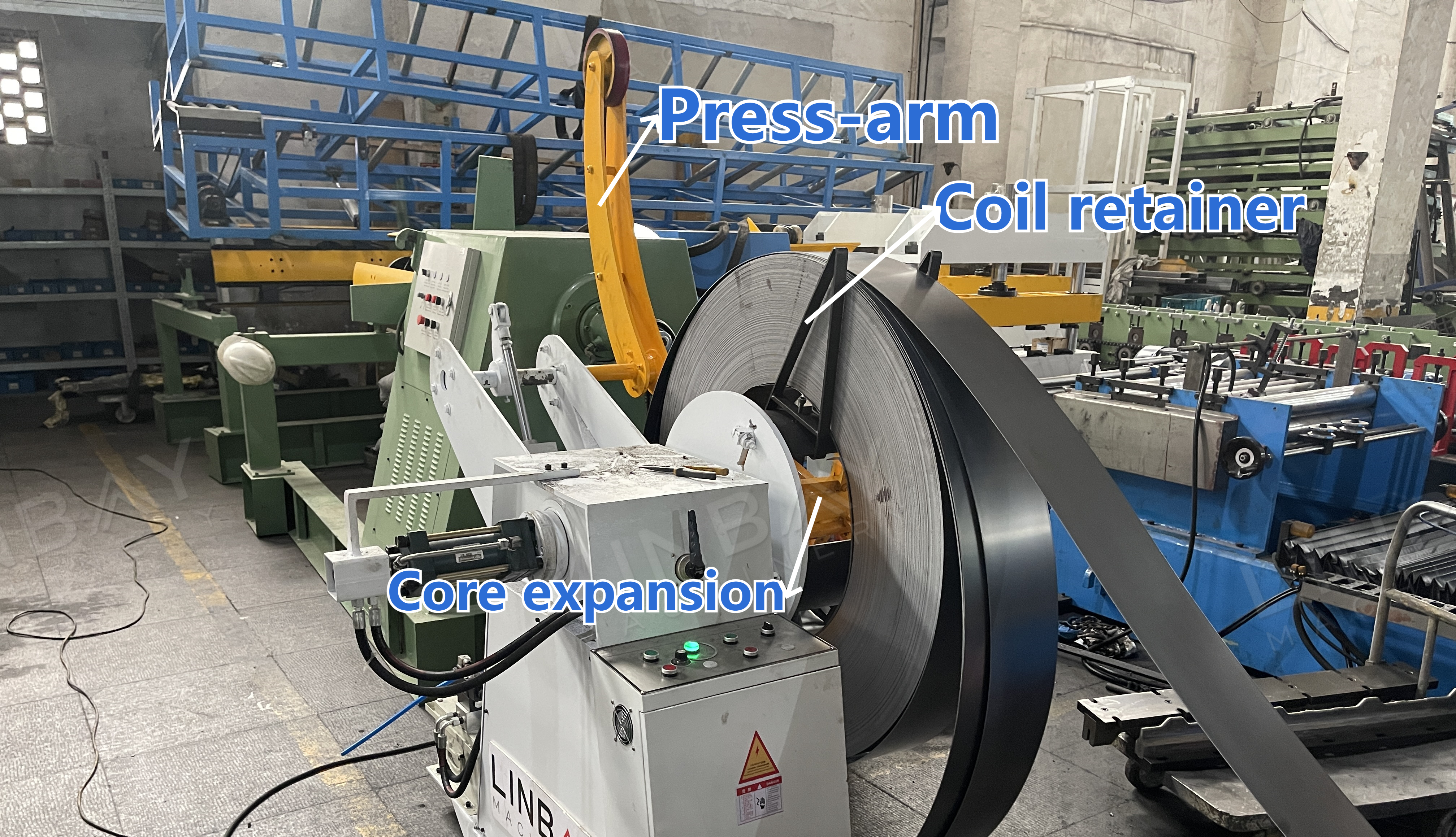

Decoiler

Lub decoiler lub hauv paus ncej txhawb nqa cov hlau kauj thiab ua raws li cov khoom siv nthuav dav, ua kom cov coils nrog ib txoj kab uas hla ntawm 490-510mm. Cov khoom siv xovxwm ntawm lub decoiler ruaj ntseg lub kauj thaum lub sijhawm thauj khoom, tiv thaiv nws los ntawm qhov qhib qhib vim qhov nro sab hauv thiab ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm.

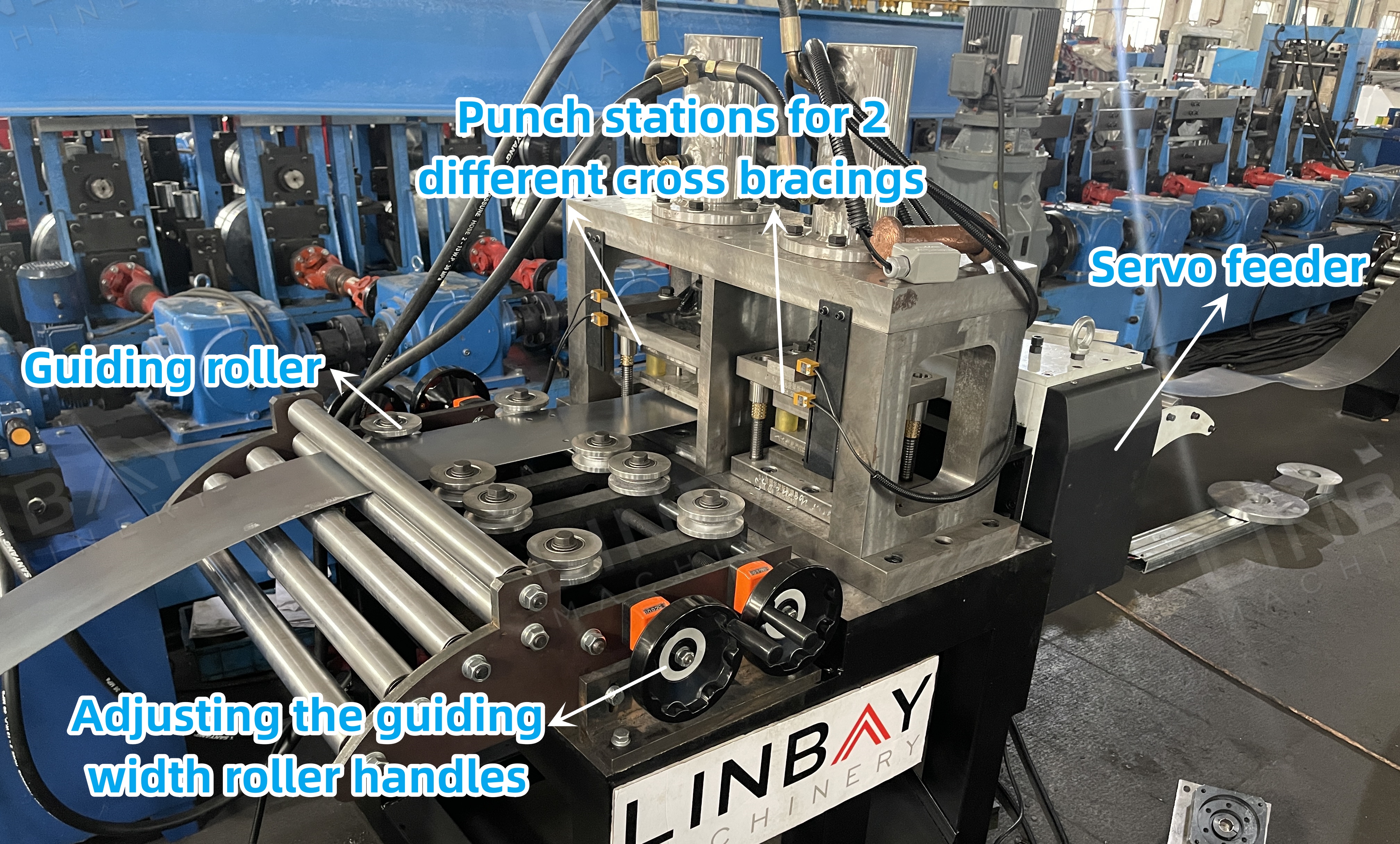

Hydraulic Punch & Servo Feeder

Lub hydraulic punch, siv los ntawm qhov chaw nres tsheb hydraulic, tsim qhov hauv cov hlau kauj. Hla bracing yog xuas nrig ntaus ntawm ob qho kawg, nyob rau ntawm flange lossis hauv qab, raws li qhov yuav tsum tau ua. Muaj standalone thiab integrated hydraulic punch tshuab. Hom kev sib koom ua ke sib koom tib lub hauv paus nrog yob txoj kev tshuab thiab nres lwm lub tshuab thaum xuas nrig ntaus.

Cov kab ntau lawm no siv cov qauv standalone, ua kom lub decoiler thiab tsim tshuab ua haujlwm tsis tu ncua thaum xuas nrig ntaus, kom ntseeg tau tias tsis muaj kev cuam tshuam ntau lawm. Lub standalone version muaj xws li ib tug servo feeder tsav los ntawm lub servo lub cev muaj zog, uas minimizes pib-nres ncua sij hawm thiab precisely tswj lub kauj qhov ua ntej ntev kom raug xuas nrig ntaus. Lub pneumatic feed mechanism nyob rau hauv lub feeder tiv thaiv lub coil nto los ntawm khawb.

Kev taw qhia

Kev cob qhia cov menyuam ua kom muaj kev sib raug zoo ntawm lub kauj thiab lub tshuab kom tsis txhob muaj kev cuam tshuam thaum lub sijhawm tsim, vim qhov ncaj ntawm tus ntoo khaub lig bracing ncaj qha cuam tshuam rau tag nrho kev ruaj ntseg ntawm lub txee.

Roll Forming Tshuab

Lub tshuab tsim no boasts ib tug cam khwb cia hlau qauv thiab ib tug gearbox system. Nws yog ib qho tseem ceeb kom nco ntsoov tias ob kab tsis tuaj yeem ua haujlwm ib txhij. Rau kev muaj peev xwm ntau lawm, peb pom zoo kom muaj cov kab ntau lawm rau txhua qhov loj.

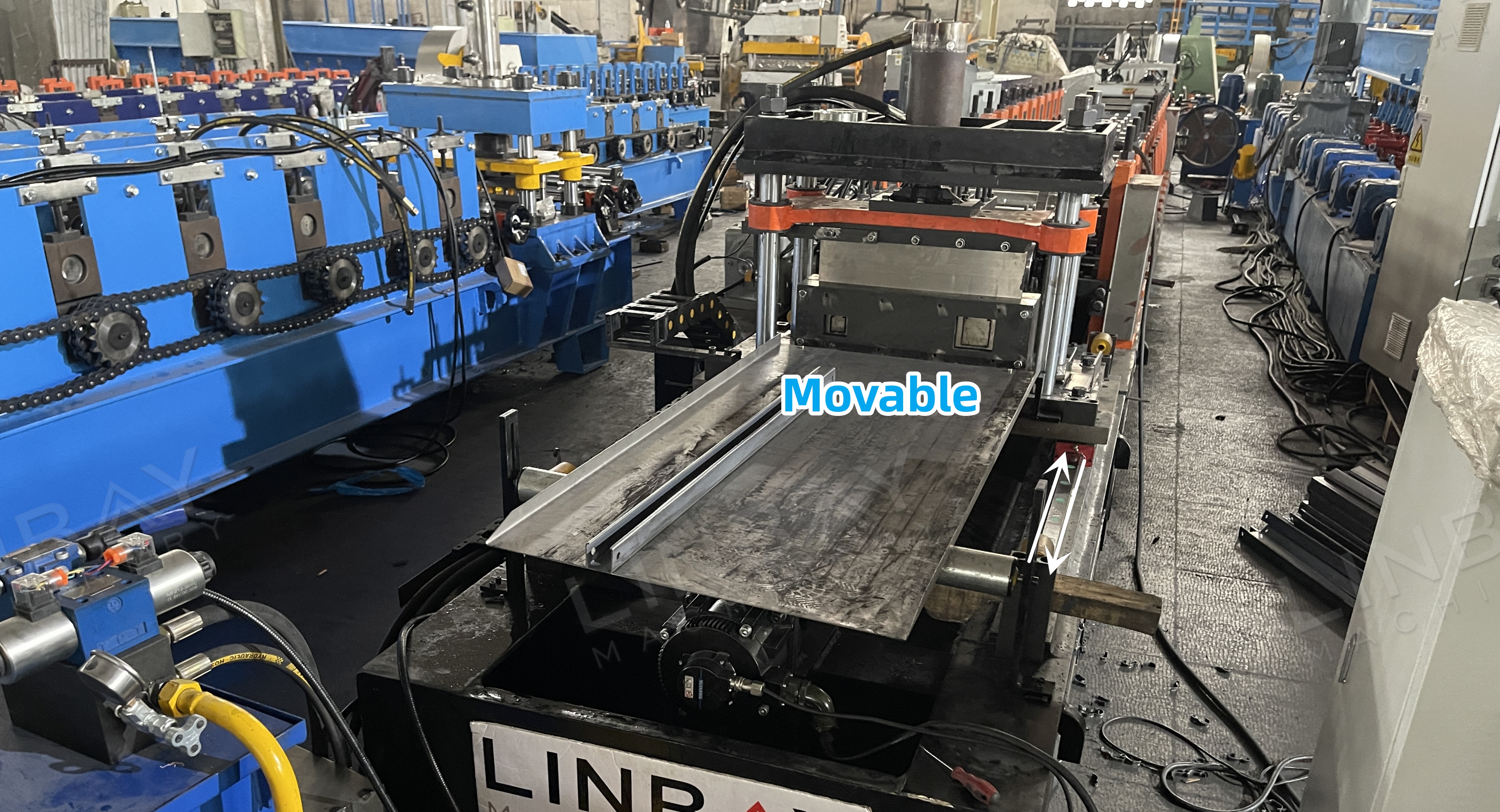

Flying Hydraulic Txiav

Tus tsim "ya" ua rau lub hauv paus ntawm lub tshuab txiav kom txav mus raws ib txoj kev, tso cai rau kev sib txuas txuas ntxiv los ntawm kev sib sau tshuab yam tsis muaj kev cuam tshuam rau kev txiav, yog li txhim kho tag nrho cov kab nrawm.

Cov hniav txiav yuav tsum tau ua kom haum rau cov duab profile, yuav tsum muaj cov hniav sib txawv rau txhua qhov loj.

Optional Device: Shear Butt Welder

Lub shear welder integrates ob qho tib si shearing thiab welding zog, tso cai rau kev sib txuas ntawm cov tshiab thiab qub steel coils. Qhov no txo cov khoom pov tseg, txo lub sijhawm hloov coil, thiab ua kom yooj yim kho. Nws siv TIG vuam los xyuas kom meej cov pob qij txha du thiab tiaj tus.

Chaw nres tsheb Hydraulic

Lub chaw nres tsheb hydraulic nta cov kiv cua txias kom ua kom muaj cua sov kom zoo, ua kom muaj kev ua haujlwm tsis tu ncua thiab txhim kho cov khoom tsim tau. Nws tau lees paub rau nws txoj kev ntseeg siab thiab kev ua haujlwm ntev.

PLC Tswj txee & Encoder

Lub encoder hloov qhov ntsuas qhov ntev ntawm lub kauj mus rau hauv cov teeb liab hluav taws xob rau PLC tswj txee. Cov txee no tswj cov khoom ceev, cov zis ib lub voj voog, thiab txiav ntev. Ua tsaug rau cov lus qhia meej ntawm tus encoder, lub tshuab txiav ua tiav qhov raug txiav hauv ± 1 hli.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj