yees duab

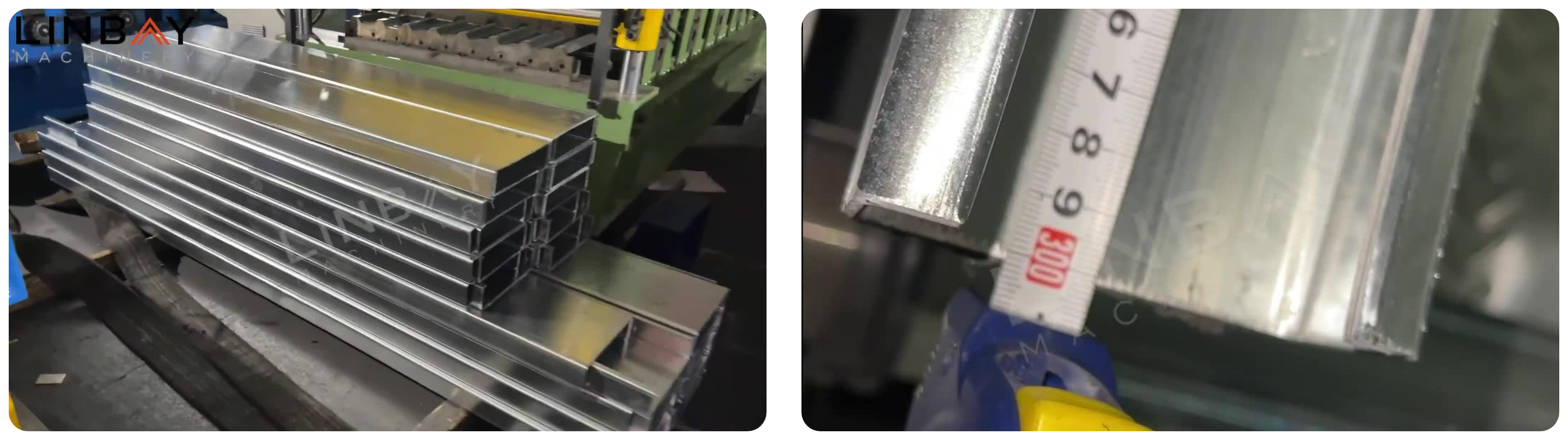

Qhov zoo

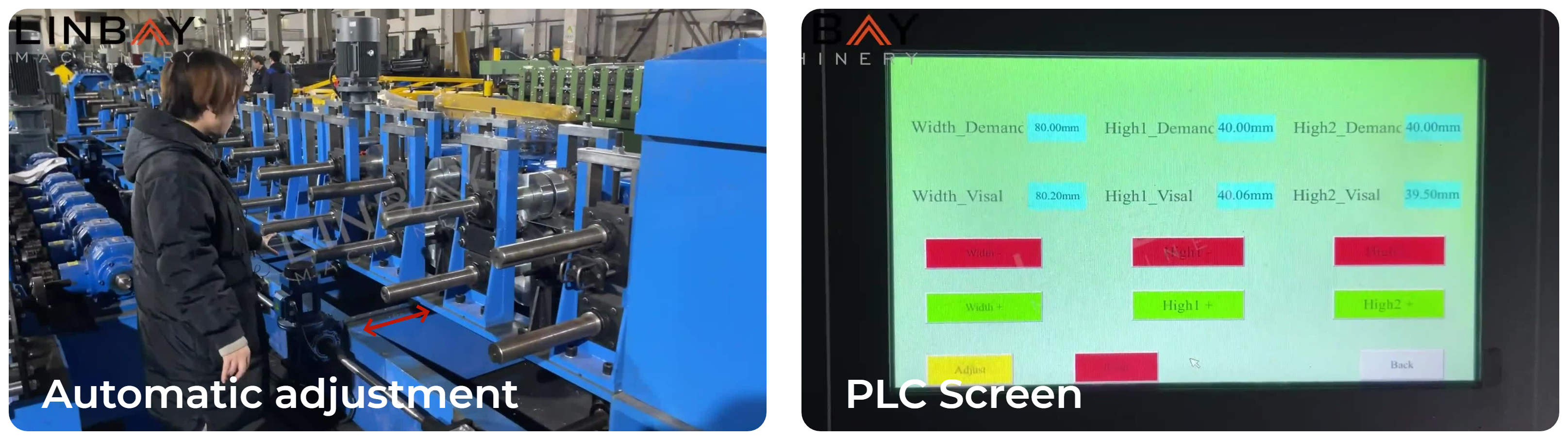

1. Ua cov purlins nrog ntau qhov dav thiab qhov siab.

2. Tsis siv neeg hloov me me, ua haujlwm yooj yim, thiab ua haujlwm siab.

3. Txiav tsis muaj khib nyiab.

Profile

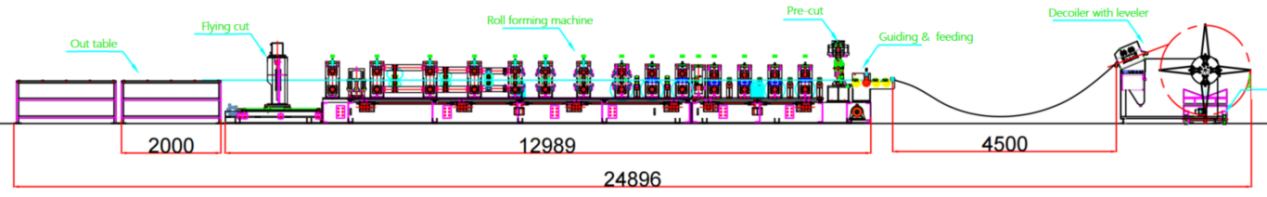

Flow daim ntawv qhia

Decoiler nrog leveler-Guiding-Pre txiav-Yav dhau los-Yav hydraulic txiav-Out rooj

Decoiler nrog leveler

Qhov no yog lub tshuab ua ke uas sib xyaw ua ke ntawm decoiler thiab qib qib, zootxuag chaw Hoobkas.Thaum cov hlau coil thickness ntau tshaj 1.5 millimeters los yog cov khoom siv lub zog tawm los tshaj 300 MPa, lub leveler yog qhov tseem ceeb. Nws tshem tawm irregularities nyob rau hauv lub steel kauj,txhim kho nws flatness thiab parallelism, yog li txhim kho qhov zoo ntawm cov hlau kauj thiab cov khoom purlin kawg.

Peb kuj tau koom ua kenias-armkom ruaj ntseg steel coils, tiv thaiv kev npaj txhij txog unwinding thaum lub sij hawm hloov txheej txheem. Ibsab nraud coil retainerntxiv tiv thaiv coil slippage. Cov qauv no yog siv los xyuas kom meejkev nyab xeeb ntawm cov neeg ua haujlwm.

Coj cov menyuam

Cov hlau kauj dhau los ntawm kev taw qhia cov menyuam ua ntej nkag mus rau hauv qib. Ntau cov kev taw qhia chais yog qhov chaw ua haujlwm kom cov hlau kauj ua raws li lub tshuab lub hauv paus,tiv thaiv distortion nyob rau hauv cov tsim profiles.

Pre txiav

los pabqhov yooj yim thiab muaj txiaj ntsig hloov ntawm steel coils nrog qhov dav sib txawvrau ntau qhov ntau thiab tsawg thiab kom tsis txhob muaj cov khoom siv khib nyiab, lub tshuab txiav ua ntej tau tsim.

Roll qub

Qhov no yob txoj kev tshuab nta ib tug robustcam khwb cia hlauqauv, muab tshwj xeeb stability thiab durability. Nws yog nruab nroggearbox thiab universal sib koomkev tsav tsheb, kom ntseeg tau tias kev ua haujlwm zoo ntawm 4 hli tuab steel coils nrog lub zog ntau dua.

Lub tshuab muaj peev xwm ua tau purlins ntawmsib txawv qhov siab thiab dav, nrog kev hloov kho tau los ntawm covPLC tswj vaj huam sib luag. Cov motors thiab reducers pab txhawb kev txav ntawm kev tsim cov chaw nres tsheb ntawm cov ntsia hlau, tom qab ntawd kev hloov pauv hauv qhov siab thiab qhov dav tau ua tiav los ntawm kev sib txawv ntawm qhov sib txawv ntawm sab laug thiab sab xis tsim cov chaw nres tsheb.

Flying hydraulic txiav

Lub tshuab txiav no yog siv los ntawm qhov chaw nres tsheb hydraulic. Raws li tau piav qhia, ib txheej ntawm cov hniav tuaj yeem haumpeb qhov sib txawv.Lub tshuab txiav slanted zoo ib yam li ob lub txiab, kom ntseeg tau tias asmooth, burr-dawb thiab nkim-dawbtxiav nto. Lub sij hawm "Flying" txhais tau hais tias lub tshuab txiav tuaj yeem txav mus los hauv kev sib koom tes nrog lub tshuab yob txoj kev ceev, tsis muaj kev cuam tshuam nws txoj haujlwm tsis tu ncua, yog litxhim kho cov khoom tsim tau.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj