yees duab

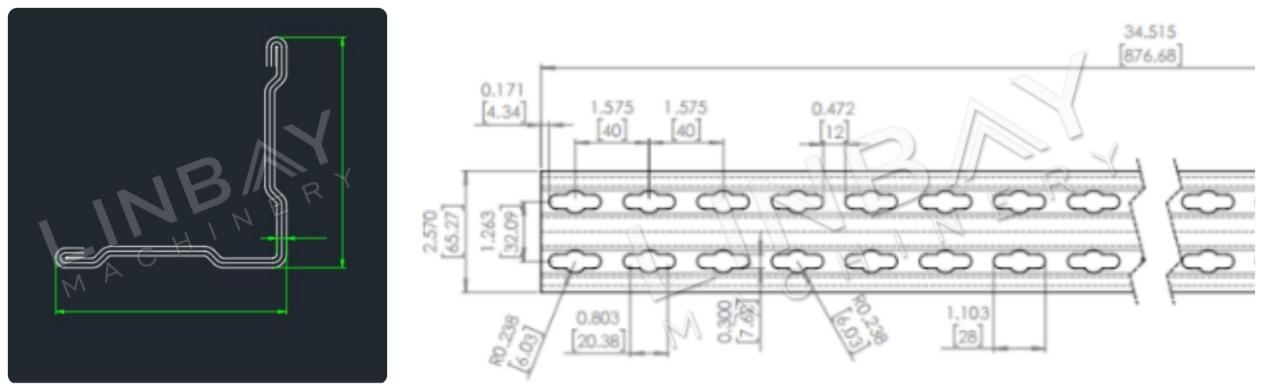

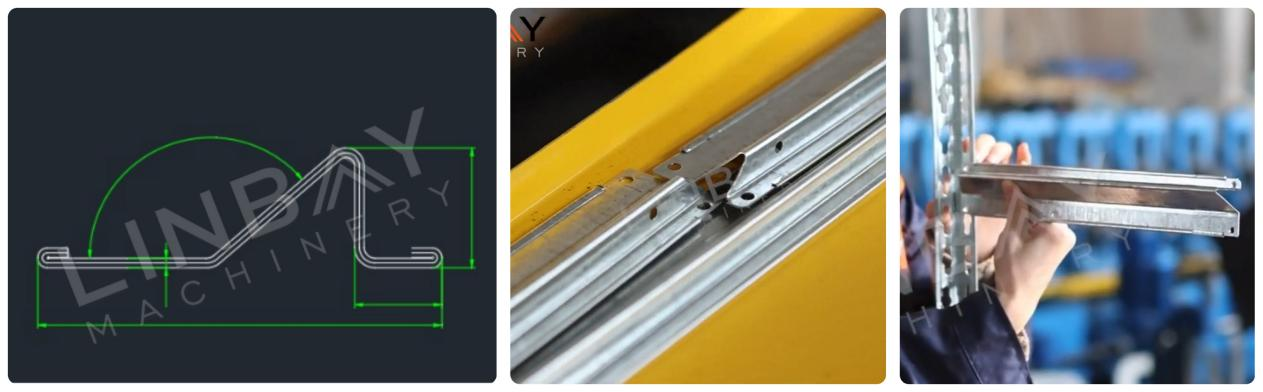

Profile

Qhov no yog lub teeb-ua haujlwm txee upright, zoo li lub kaum sab xis steel, nrog lub thickness ntawm 1.2 hli. Nws yog ib qho tseem ceeb ntawm cov qauv txee, thiab nws qhov ncaj ncaj cuam tshuam rau lub peev xwm ntawm lub txee. Qhov yog xuas nrig ntaus ntawm ob sab kom txuas cov kab teeb.

Qhov no yog lub teeb-ua haujlwm txee beam, 1.2mm tuab, npaj los txhawb cov txee txee thiab txhim kho tag nrho cov khoom muaj peev xwm ntawm cov txee lub teeb.

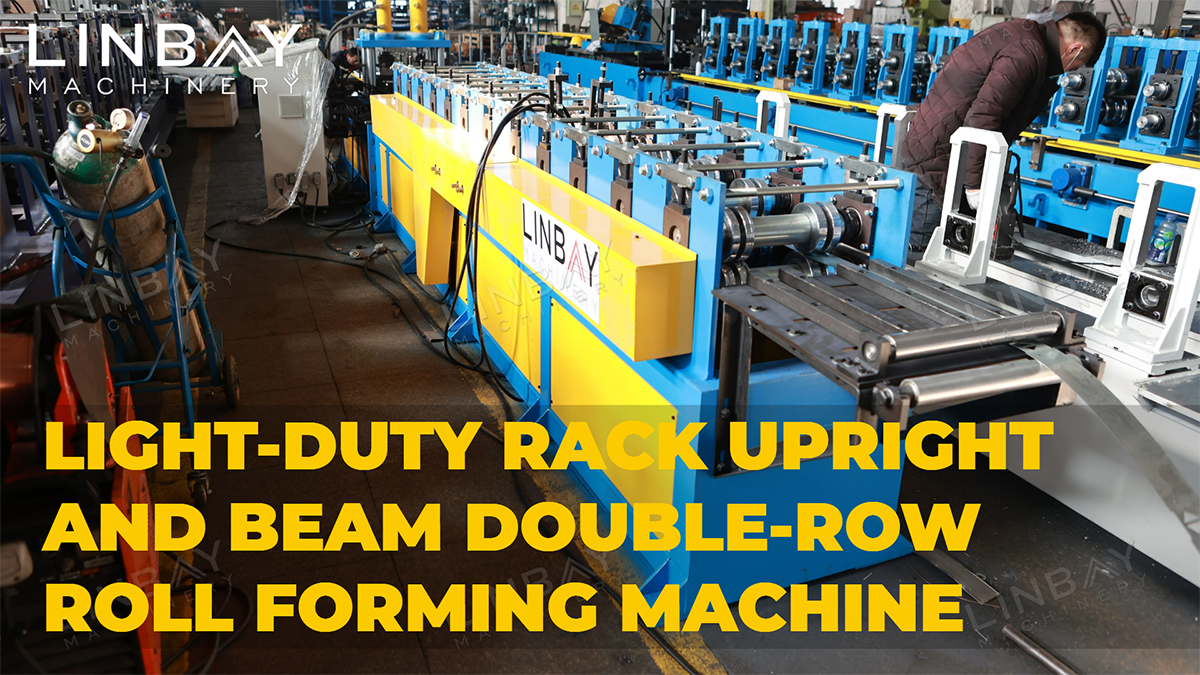

Kev piav qhia

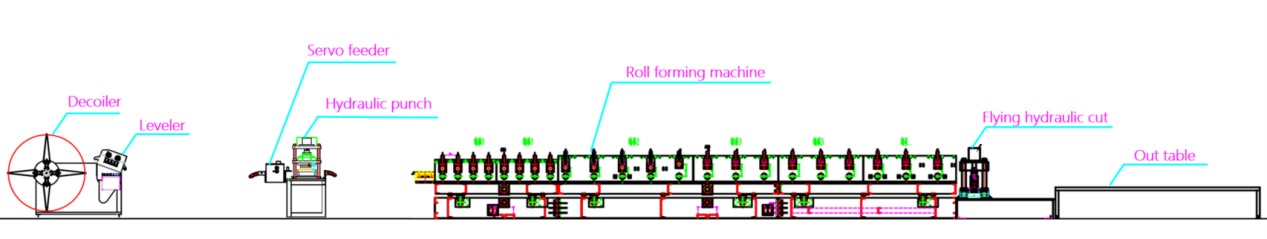

Flow daim ntawv qhia

Decoiler nrog Leveler

Lub tshuab no ua ke ua ke decoiling thiab leveling functionality.Nws suav nrog cov cuab yeej nres ntawm lub decoiler rau kev kho decoiling cov menyuam nro, kom ntseeg tau qhov nrawm. Tiv thaiv steel nplooj tiv thaiv coil slipping. Qhov no tsim muaj ibnqi-zoo, siab-kev ruaj ntsegdecoiling kua.

Tom qab ntawd, steel kauj nkag mus rau hauv lub tshuab leveling. Ntawm 1.2mm tuab, ntom xuas nrig yuav tsum tau ua kom tiav kom tshem tawm cov coil curvature, txhim khoflatness thiab parallelismrau kev txhim kho cov khoom zoo. Lub leveler muaj 3 sab sauv thiab 4 qis rollers.

Servo Feeder & Hydraulic Punch

Cov hlau kauj mus rau ib qho kev ywj pheej hydraulic punch tshuab. Siv lub servo lub cev muaj zog rau lub feeder enables meej xuas nrig ntaus vim nws cov lus teb ceev ceev thiab tsawg kawg pib-nres lub sij hawm, kom ntseeg tau raug punching txoj hauj lwm tswj.

Txwv

Thaum lub sij hawm xuas nrig ntaus thiab yob txoj kev, ib tug limiter yog ua hauj lwm rausynchronize ntau lawm ceev. Thaum lub steel kauj mus txog qhov qis limiter, qhia tias lub punching ceev dua li yob txoj kev ceev, hydraulic punch tau txais lub teeb liab nres los ntawm PLC tswj txee. Lub tswb ceeb toom qhia ntawm PLC npo, tso cai rau tus neeg teb xov tooj rov ua haujlwm nrog lub vijtsam nyem. Lub caij no, thaum lub sijhawm ncua, lub tshuab yob txoj kev ua haujlwm txuas ntxiv mus.

Piv txwv li, thaum lub steel coil hits lub sab sauv limiter, qhia ntau dua kev sib sau ceev tshaj punching ceev, yob txoj kev tshuab nres. Thaum lub sijhawm luv luv ntawm lub yob txoj kev tshuab nres thiab rov pib dua, hydraulic punch tseem ua haujlwm.Qhov siab ntawm lub siab limiter yog adjustable raws li tus neeg yuav tsum tau muaj.

Qhov no ua kom muaj kev sib koom ua ke tag nrho thiab kev sib koom ua ke ntawm cov kab ntau lawm.

Kev taw qhia

Ua ntej cov hlau kauj nkag mus rau qhov pib tsim cov menyuam, nws hla txoj kev taw qhia kom muaj kev sib haum xeeb nrog lub tshuab, tiv thaiv qhov profile distortion. Kev taw qhia rollers yog qhov chaw nyob tsis tau tsuas yog ntawm qhov nkag tab sis kuj nyob ntawm tag nrho cov kab sib sau. Kev ntsuas ntawm txhua qhov kev taw qhia bar / cov menyuam qhov kev ncua deb mus rau ntawm ntug yog sau tseg rau hauv phau ntawv qhia kom raug hloov kho nyob rau hauv cov ntaub ntawv ntawm kev hloov pauv thaum thauj los yog cov neeg ua haujlwm raug yuam ua haujlwm thaum lub sijhawm tsim khoom.

Roll Forming Tshuab

Lub tshuab yob txoj kev sawv ua lub ntsiab lus tseem ceeb ntawm tag nrho cov kab ntau lawm. Nrog12 qhov chaw ua haujlwm, nws khav aphab ntsa vaj huam sib luag qauv thiab saw tsav tsheb system. Tshwj xeeb, nws yog aob kabtsim muaj peev xwm crafting ob leegupright thiab beam duab rau lub teeb-lub luag hauj lwm shelving. Thaum cov kab no tsis tuaj yeem ua haujlwm ib txhij, lawv muabyoojrau ntau yam kev xav tau. Kev tiv thaiv npog ntawm cov saw tseem ceeb rau cov neeg ua haujlwm kev nyab xeeb. Tsis tas li ntawd, lub tshuab tau sim nrog cov hlau coils ntawm qhov sib npaug ntawm cov khoom siv zog rau cov neeg siv khoom tsim khoom, kom ntseeg tau yooj yim tam sim ntawd thaum xa khoom.

Cov txheej txheem rollers yog crafted los ntawmGcr15, high-carbon chromium bearing steel renowned rau nwshardness thiab hnav tsis kam. Chrome plating ntawm cov menyuam nto ua rau nws lub neej ntev, thaum lub shafts yog tsim los ntawm kev kho cua sov40 Crkhoom.

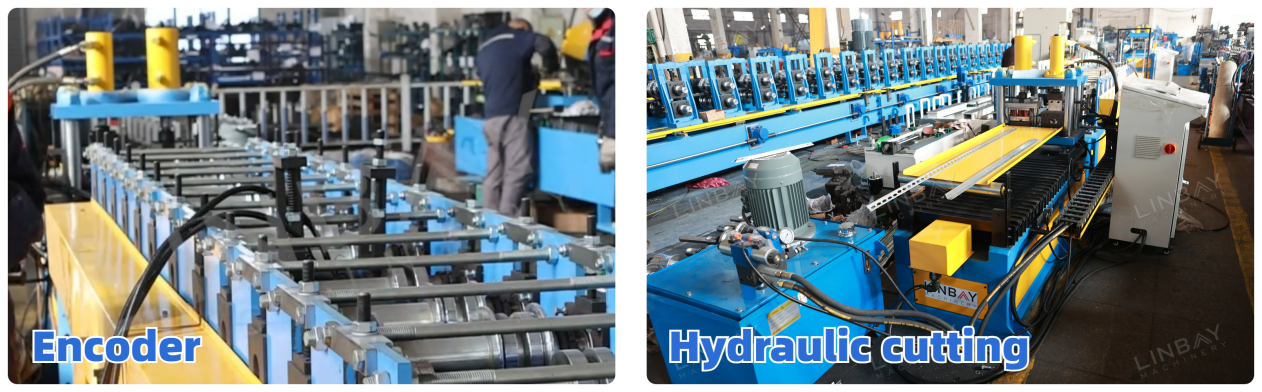

Flying Hydraulic Txiav & Encoder

Lub tshuab yob txoj kev sib koom ua ke nrog Japanese Koyo encoder, hloov qhov kev xav ntawm steel coil ntev mus rau hauv hluav taws xob cov cim xa mus rau PLC tswj txee. Qhov no enables lubtxiav tshuab los tswj kev txiav tsis pub dhau 1 hli, kom ntseeg tau cov khoom zoo thiab txo cov khoom pov tseg los ntawm kev txiav tsis raug. "Flying" txhais tau hais tias lub tshuab txiav lub peev xwm txav rov qab thiab tawm ntawm tib qhov ceev raws li lub tshuab yob txoj kev thaum txiav,ua kom muaj kev ua haujlwm tsis tu ncua thiab txhim kho tag nrho cov kab ntau lawm.

Chaw nres tsheb Hydraulic

Lub chaw nres tsheb hydraulic yog nruab nrog lub tshuab hluav taws xob cua txias rauua kom sov dissipation, xyuas kom lub sijhawm ntev, ua haujlwm tsis zoo, thiab ua haujlwm ntev.

PLC

Cov neeg ua haujlwm tuaj yeem tswj hwm kev tsim khoomceev, teem ntau lawm qhov ntev, txiav lengths, thiab lwm yam., los ntawm PLC screen. PLC tswj txee suav nrog kev tiv thaiv kev ua haujlwm xws li overload, luv Circuit Court, thiab tiv thaiv theem poob. Cov lus tso tawm ntawm PLC screen tuaj yeem ua taucustomized rau ib hom lus lossis ntau hom lusraws li cov neeg siv khoom xav tau.

Warranty

Ua ntej xa khoom, hnub xa khoom yog qhia rau ntawm daim ntawv teev npe, pibib tug ob-xyoo lav rau tag nrho cov ntau lawm kab thiab ib tug tsib-xyoo warranty rau rollers thiab shafts.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj