Kev piav qhia

Qhov C / U Purlin Roll Forming Tshuab, tuaj yeem tsim C zoo thiab U zoo purlins los ntawm 100-400mm ntawm qhov dav thiab yooj yim los hloov spacers. Qhov siab tshaj plaws thickness tuaj yeem tsim ntawm 4.0-6.0mm.

Tsis tas li ntawd peb tuaj yeem tsim lub tshuab no los ua haujlwm nrog txhua qhov dav ntawm purlins thiab cov channel tseem ceeb, tuaj yeem kho tau los ntawm PLC tswj lossis kho lub log hloov pauv cov ntawv dav. Qhov no yooj yim dua li kho cov spacers thiab tuaj yeem txuag sijhawm ntau dua. Hais txog lub tshuab txiav, koj tuaj yeem xaiv qhov txiav ua ntej lossis tom qab txiav.Qhov kev tsav tsheb peb txais yuav lub gimbal system yog tias cov khoom siv raw yog tuab dua 2.5 hli, qhov no muaj zog ntau zog tsav thiab ruaj khov thaum tsim cov purlins.

Technical Specification

| C / U Purlin yob txoj kev tshuab | |||

| Tsis muaj. | Yam khoom | Specification | xaiv tau |

| 1 | Cov khoom tsim nyog | Hom: Galvanized Coil, PPGI, Carbon Steel Chev | |

|

|

| Thickness (mm): 0.4-0.6, 1.5-3, 4-6 |

|

|

|

| Yield zog: 250-550MPa |

|

|

|

| Tensil stress (Mpa): G350Mpa-G550Mpa |

|

| 2 | Nominal sib sau ceev (m / min) | 10-25 | Los yog raws li koj xav tau |

| 3 | Tsim chaw nres tsheb | Raws li koj qhov profile | |

| 4 | Decoiler | Phau ntawv decoiler | Hydraulic decoiler los yog ob lub taub hau decoiler |

| 5 | Main tshuab lub cev muaj zog | Sino-German Brand | Siemens |

| 6 | PLC hom | Panasonic | Siemens |

| 7 | Inverter hom | Yaskawa | |

| 8 | Tsav tsheb | Chain tsav | Gearbox tsav |

| 9 | Rollers cov ntaub ntawv | Steel #45 | GCr15 |

| 10 | Chaw nres tsheb qauv | Phab ntsa vaj huam sib luag chaw nres tsheb | Forged Hlau chaw nres tsheb Los yog torri sawv cev |

| 11 | Punching system | No | Hydraulic punching chaw nres tsheb lossis Punching xovxwm |

| 12 | Txiav qhov system | Tom qab txiav | Pre-txiav |

| 13 | Lub zog xav tau | 380V 60Hz | Los yog raws li koj xav tau |

| 14 | Tshuab xim | Industrial xiav | Los yog raws li koj xav tau |

Flow Chart

Kev tuav decoiler --- pub mis - tshuab ua tshuab - hydraulic txiav - tawm rooj

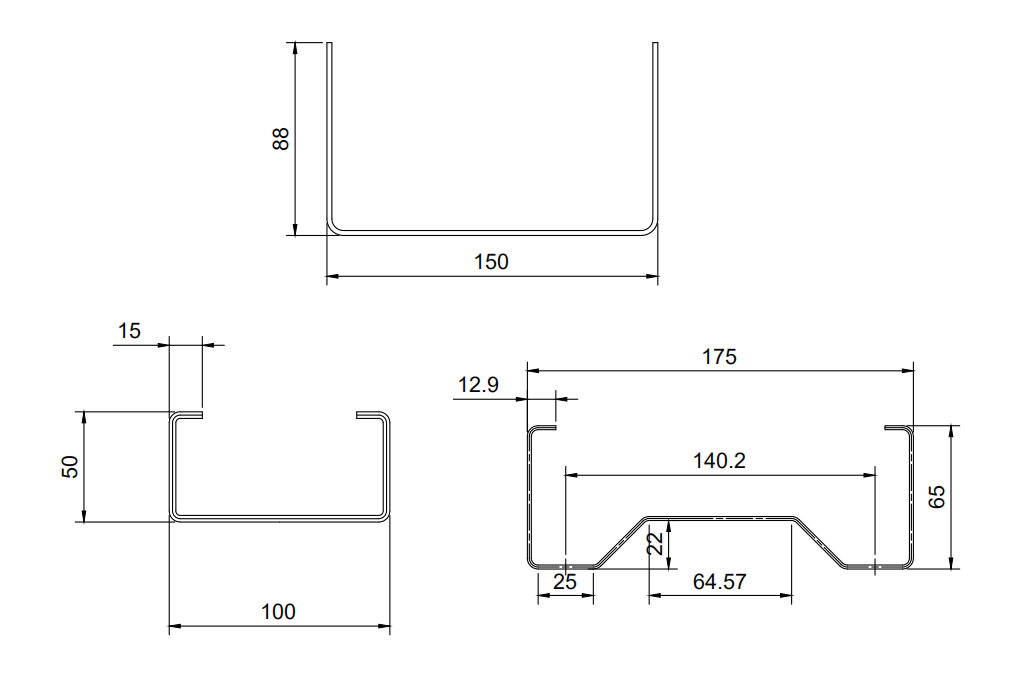

Perfil

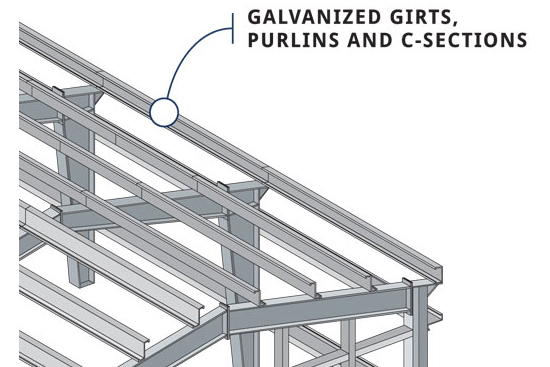

Daim ntawv thov

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj