yees duab

Profile

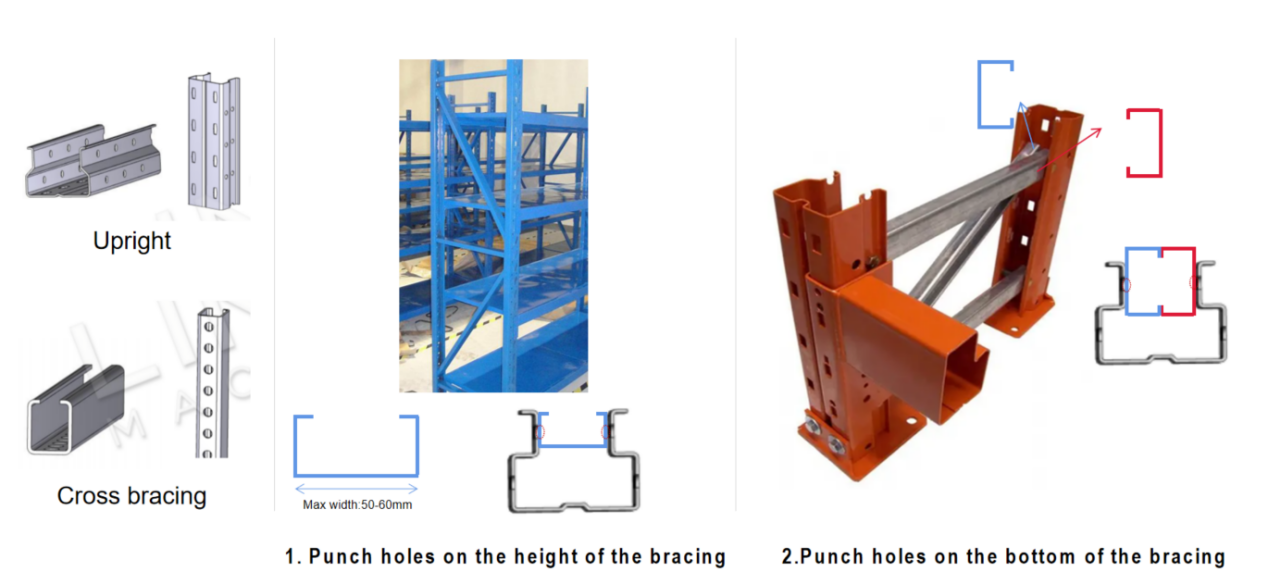

Cross bracing plays lub luag haujlwm tseem ceeb hauv cov txheej txheem txee, txhawb nqa tag nrho cov txee txee. Positioned nyob rau hauv lub khib upright, nws muaj kev txhawb ntxiv. Nyob ntawm txoj kev teeb tsa tau xaiv, qhov txuas txuas tau muab tso rau hauv kev ruaj ntseg.

* Kev Txhim Kho Txoj Kev 1: Ib txoj hlua khi ib leeg tau nruab rau hauv lub khib nyiab ncaj, yuav tsum tau ua ntej punch qhov ntawm qhov siab ntawm lub bracing rau ntsia hlau ntsia.

* Kev Txhim Kho Txoj Kev 2: Ob lub bracings tau nruab rau hauv lub khib nyiab, tseem yuav tsum tau ua ntej punch qhov nyob rau hauv qab ntawm bracing rau ntsia hlau ntsia.

Nyob rau hauv cov ntaub ntawv no, peb siv txoj kev installation 1. Peb kuj muab ib tug customizable kev tso cai rau ib txhij xuas nrig ntaus nyob rau hauv lub hauv qab thiab siab ob sab ntawm lub bracing kom yooj yooj yim.

Kev piav qhia

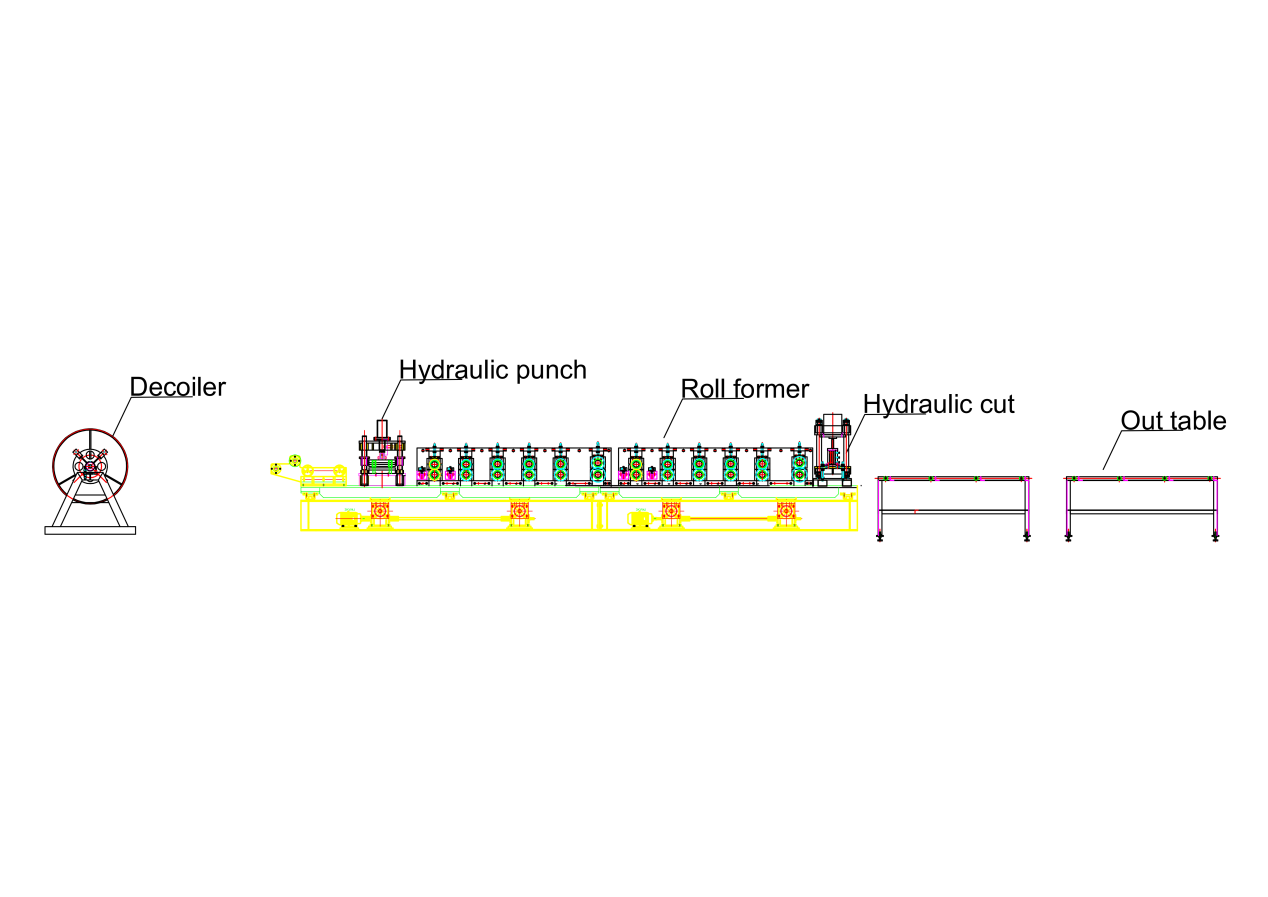

Flow daim ntawv qhia

Decoiler--Guiding--Leveler--Hydraulic punch--Roll forming tshuab--Hydraulic txiav--Out rooj

Decoiler

Lub decoiler yog nruab nrog lub xovxwm caj npab kom ruaj khov steel kauj thaum hloov, txo qhov kev pheej hmoo ntawm kev tso tawm sai sai thiab muaj peev xwm raug mob rau cov neeg ua haujlwm. Nws kuj tseem muaj cov cuab yeej nres uas tswj qhov nro ntawm cov menyuam pub noj, kom ntseeg tau tias tsis muaj qhov nrawm nrawm. Tsis tas li ntawd, cov hlau tiv thaiv cov hniav tau muab tso ua ke los tiv thaiv cov hlau kauj los ntawm kev ntog thaum lub sij hawm decoiling, txhim kho kev nyab xeeb thiab kev siv nyiaj.

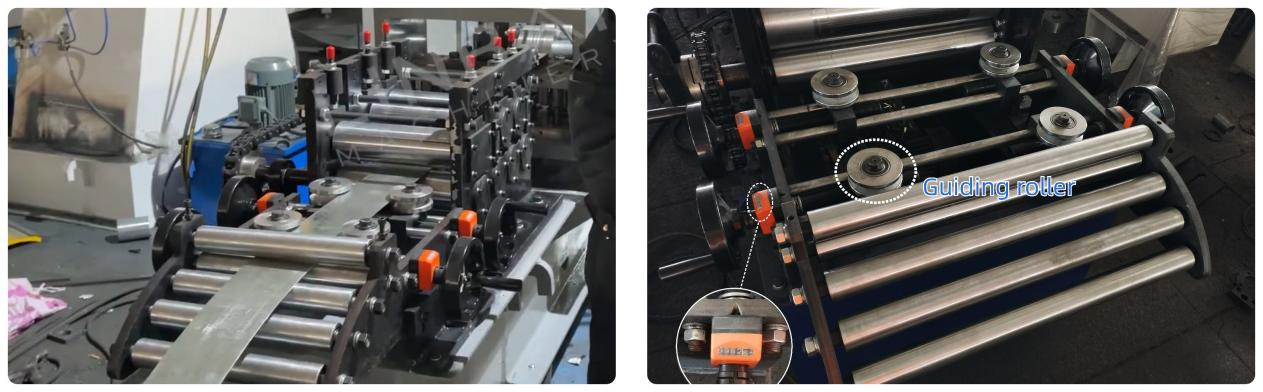

Kev taw qhia

Kev taw qhia rollers ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev sib haum xeeb ntawm cov hlau kauj thiab lub tshuab, tswj lawv raws tib qhov chaw nruab nrab kom tsis txhob cuam tshuam ntawm cov txheej txheem tsim. Cov chais no tau muab tso rau hauv qhov chaw tsis yog ntawm qhov chaw nkag, tab sis kuj thoob plaws tag nrho txoj kab. Qhov kev ncua deb ntawm txhua qhov kev taw qhia cov menyuam mus rau ntawm ntug tau sau tseg rau hauv phau ntawv ceev ceev, ua rau cov neeg ua haujlwm hloov kho meej raws li cov ntaub ntawv muab. Qhov no ua kom muaj kev sib raug zoo, txawm tias muaj kev hloov pauv me ntsis tshwm sim thaum thauj lossis kev hloov kho ntau lawm los ntawm cov neeg ua haujlwm.

Leveler

Lub tshuab leveling plays lub luag haujlwm tseem ceeb hauv kev txhim kho lub tiaj tus thiab kev sib luag ntawm cov hlau kauj, ua kom cov txiaj ntsig tau zoo. Kev sib xyaw ua ke rau hauv lub tshuab yob txoj kev, nws muaj 2 sab saum toj leveling rollers thiab 3 qis leveling rollers. Xwb, cov neeg siv khoom nrhiav kev muaj peev xwm siab dua tuaj yeem xaiv rau lub tshuab ua haujlwm ib leeg, txawm hais tias muaj cov kab ntau lawm me ntsis.

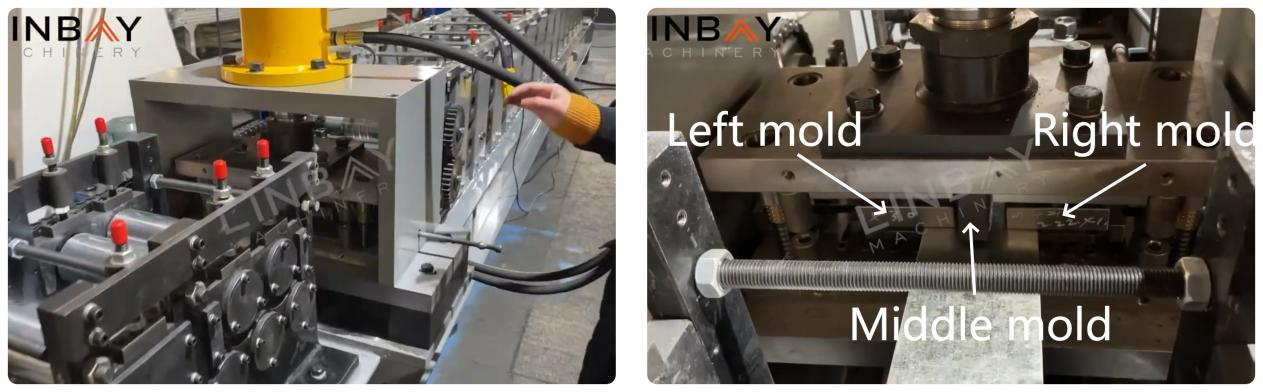

Hydraulic Punch

Lub tshuab xuas nrig ntaus hydraulic, siv los ntawm qhov chaw nres tsheb hydraulic, siv cov pwm sab laug thiab sab xis raupunch qhov precisely ntawm qhov nruab nrab ntawm qhov siab sab tom qab tsim. Tom qab txiav, ob lub qhov muaj nyob ntawm txhua qhov kawg ntawm tus ntoo khaub lig bracing rau ntsia hlau ntsia. Tsis tas li ntawd, qhov nruab nrab pwm ntawm hydraulic punch tuaj yeemimprint tus neeg siv khoom lub logontawm cov hlau kauj yam tsis muaj kev nkag mus, ua kom yooj yim rau hom kev txhawb nqa thiab kev lag luam nthuav dav.

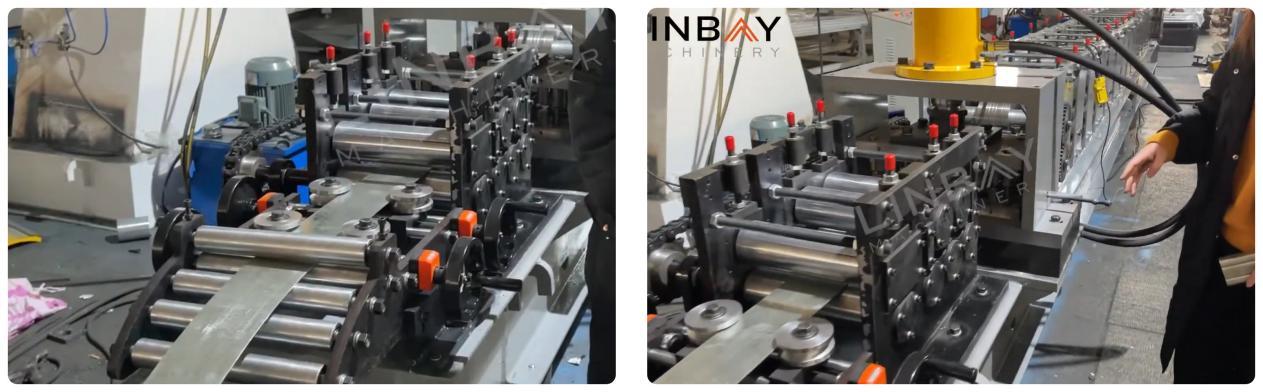

Roll Forming Tshuab

Roll forming tshuab, featuring aphab ntsa vaj huam sib luag qauv thiab saw tsav tsheb system, plays lub luag haujlwm tseem ceeb hauv cov kab ntau lawm. Configured rau cov neeg siv khoom450 MPayield zog steel coils, nws muaj22 qhov chaw ua haujlwm. Txhawm rau kom yooj yim rau kev tsim khoom tam sim ntawd thaum xa khoom, lub tshuab yob txoj kev raug sim siv steel coilsnrog tib lub zog tawm los (450MPa)raws li cov khoom siv hauv cov neeg siv khoom.

Cov txheej txheem rollers yog crafted los ntawmGcr15, high-carbon chromium-cov kabmob steel muaj npe nrov rau nws qhov tshwj xeeb hardness thiab hnav tsis kam. Chrome plating ntawm cov menyuam nto ua rau nws lub neej ntev, ua tiav los ntawm cov shafts ua los ntawm kev kho cua sov40 Crkhoom.

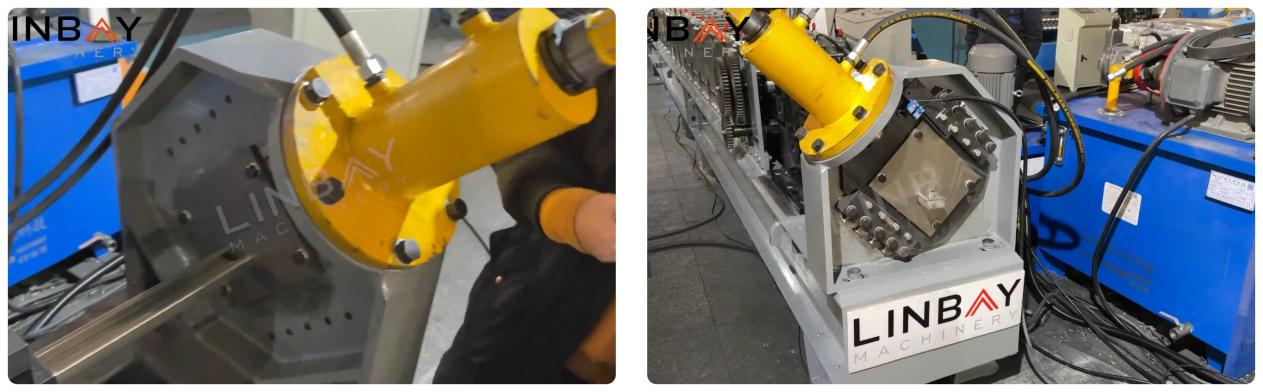

Hydraulic Txiav & Encoder

Kev sib koom ua ke ntawm Japanese Koyo encoder tso cai rau kev hloov pauv ntawm kev nkag siab ntawm steel coil ntev mus rau hauv hluav taws xob teeb liab, xa mus rau PLC tswj txee. Qhov no meej system kom paub meejtxiav raug nyob rau hauv 1 hli,yog li lav cov khoom zoo thaum txo cov khoom pov tseg uas tshwm sim los ntawm kev txiav tsis raug.

Chaw nres tsheb Hydraulic

Lub chaw nres tsheb hydraulic yog nruab nrog lub kiv cua txias kom ua kom muaj cua sov kom zoo, ua kom lub sijhawm ntev, ua haujlwm tsis zoo thiab ua haujlwm ntev.

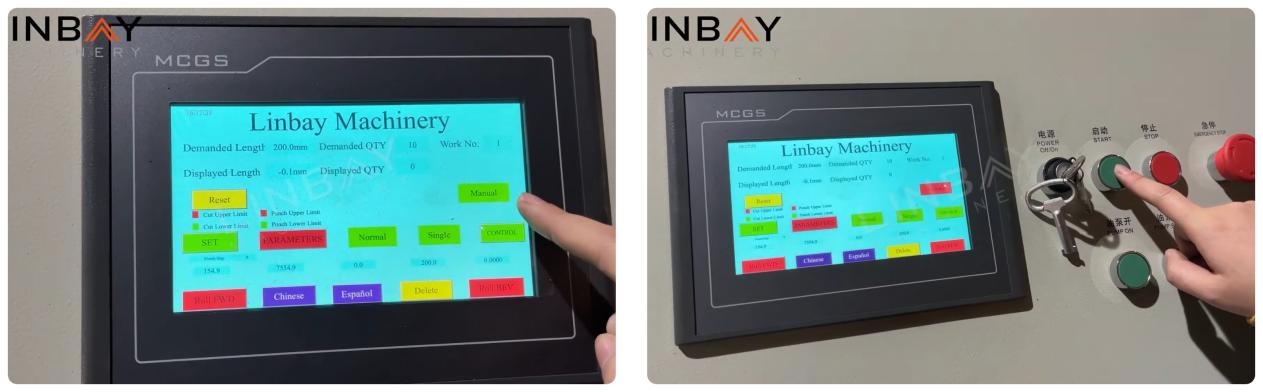

PLC tswj txee

Cov neeg ua haujlwm muaj peev xwm tswj hwm kev ua haujlwm ceev, tsim qhov ntev ntawm cov khoom, thiab txiav txim siab txiav qhov ntev ntawm PLC screen. PLC tswj txee yog nruab nrog kev tiv thaiv nta xws li overload, luv luv Circuit Court, thiab tiv thaiv theem poob. Tsis tas li ntawd, cov lus tso tawm ntawm PLC screentuaj yeem ua raws li hom lus tshwj xeeb lossis ntau hom luskom tau raws li qhov nyiam ntawm cov neeg siv khoom.

Warranty

Hnub xa khoom yog qhia rau ntawm daim ntawv teev npe, pib lubob xyoos lav rau tag nrho cov kab ntau lawm thiab tsib xyoos lav rau cov menyuam thiab cov ncej.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj