yees duab

Profile

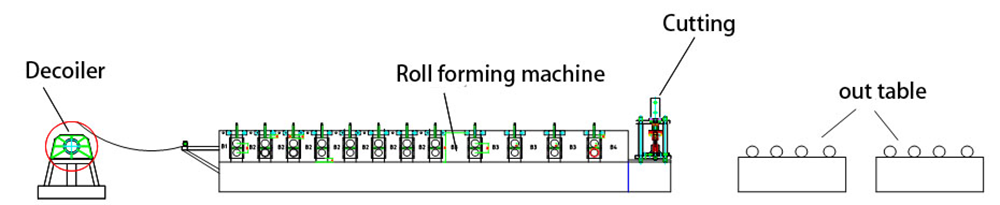

Decoiler--Yav dhau los--Hydraulic txiav--Out rooj

7.5 Tuj Hydraulic Decoiler

Rau cov kab ntau lawm no, peb ntiav hydraulic decoiler uas muaj peev xwm tuav tau txog li 7.5 tons. Muab qhov tsim nyog rau dav hlau coils hauv kev tsim cov vaj huam sib luag trapezoidal, cov txheej txheem hloov coil nthuav qhia kev nyab xeeb rau cov neeg ua haujlwm. Txhawm rau txo cov kev pheej hmoo no, cov nplooj hlau tiv thaiv raug ntsia rau sab nraud ntawm lub kauj kom tsis txhob ntog thaum lub sij hawm decoiling,hais txog qhov tseem ceeb ntawm kev nyab xeeb ntawm cov neeg ua haujlwmhauv peb qhov kev txiav txim siab tsim.

Ib qho yeemtsheb thauj khoommuaj, pab nyob rau hauv kev thauj mus los ntawm coils mus rau lub decoiler. Cov cuab yeej no pab txuag lub sijhawm thiab txhim kho kev nyab xeeb ntawm cov neeg ua haujlwm, tshwj xeeb hauv cov chawtsis muaj nyiaj siv ua haujlwm cranes.

Roll Forming Tshuab

Lub tshuab yob txoj kev ua haujlwm yog qhov tseem ceeb hauv cov kab ntau lawm, boasting 20 qhov chaw tsim khoom hauv tag nrho. Nws siv cov vaj huam sib luag phab ntsa thiab cov saw tsav tsheb. Cov txheej txheem rollers, crafted los ntawmGcr15, high-carbon chromium-cov kabmob steel, muajTshwj xeeb hardness thiab hnav tsis kam. Chrome plating ntawm cov menyuam nto txuas ntxiv nws txoj sia, thaum lub shafts yog tsim los ntawm kev kho cua sov40 Crkhoom.

Kev tiv thaiv npog ntawm cov saw hlau pab tiv thaiv cov plua plav los yog cov khoom tawg los ntawm kev puas tsuaj rau cov saw hlau, yog li ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm. Roll forming tshuab undergoeskuaj siv steel coils nrog tib lub zog tawm losRaws li cov neeg siv khoom tsim khoom, ua kom yooj yim tsim khoom thaum xa khoom.

Hydraulic Txiav & Encoder

Lub tshuab yob txoj kev sib koom ua ke ntawm Koyo encoder los ntawm Nyiv, uas hloov cov hlau coil ntev rau hauv cov hluav taws xob xa mus rau PLC tswj txee. Qhov no meej system enableslub tshuab txiav kom tswj tau qhov tsis raug ntawm kev ua siab ntev ntawm 1mm, kom ntseeg tau cov khoom zoo thiab txo cov khoom pov tseg los ntawm kev txiav tsis raug. Powered los ntawm qhov chaw nres tsheb hydraulic, lub tshuab txiav hydraulic muab lub zog txiav.Nws cov txheej txheem txiav tsim tsis muaj pov tseg, tawm hauv cov npoo du yam tsis muaj burrs.Peb ua tib zoo sim cov yob txoj kev tshuab kom txog thaum nws tsim ib qhov profile uas phim cov duab kos, tom qab ntawd peb tsim cov pwm pwm raws li cov qauv. Txawm hais tias txoj hauv kev no tuaj yeem ua rau lub sijhawm thiab cov nqi zog nce ntxiv, lub tshuab txiav tau nthuav tawm cov npoo tshwj xeeb uas tsis muaj burrs.

Chaw nres tsheb Hydraulic

Nruab nrog cov kiv cua txias txias, peb qhov chaw nres tsheb hydraulic ua kom muaj cua sov kom zoo, tso cai rau kev ua haujlwm tas mus li thiab txias, yog li txhim kho kev ua haujlwm zoo. Nrog rau tus nqi qis tsis ua hauj lwm thiab lub sij hawm ntev, peb qhov chaw nres tsheb hydraulic yog txhim khu kev qha thiab tsim kom kav ntev.

PLC tswj txee

Cov neeg ua haujlwm muaj peev xwm tswj hwm qhov nrawm, kho qhov ntev ntawm cov khoom, txiav qhov ntev, thiab ntau dua ntawm PLC screen. PLC tswj txee yog nruab nrogtiv thaiv kev ua haujlwmsuav nrog overload, luv Circuit Court, thiab tiv thaiv theem poob. Tsis tas li ntawd, cov lus tso tawm ntawm PLC screentuaj yeem hloov kho kom tau raws li cov neeg siv khoom tshwj xeeb, haum rau ib leeg lossis ntau hom lus raws li xav tau.

Tsis tu ncua Tawm Rooj & Yeem: Nws pib Stacker

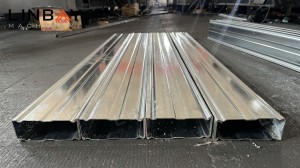

Lub vaj huam sib luag trapezoidal no yog cov txheej txheem vov tsev thiab cov khoom siv cladding dav siv hauv Romania thoob plaws ntau yam kev siv xws li kev lag luam thiab kev tsim kho, cov tsev khaws khoom me me, cov tsev, thiab cov chaw ua liaj ua teb.

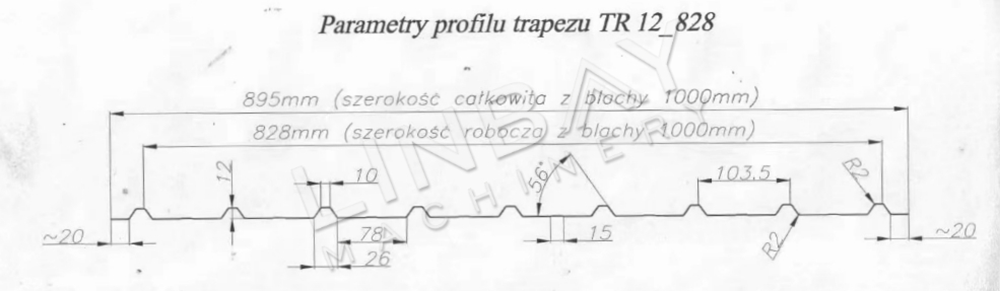

Tsim los ntawm cov txheej txheem txias yob txoj kev, lub vaj huam sib luag no muaj qhov dav dav ntawm 895mm, npog dav ntawm 828mm, thiab nta 12mm yoj qhov siab, nrog rau sab sauv thiab qis nthwv dej dav ntawm 10mm thiab 26mm feem. Lub yoj suab ntsuas 78mm. Nws muaj nyob rau hauv thicknesses xws li 0.3mm mus rau 0.6mm thiab yuav ua tau siv galvanized steel, txhuas hlau, los yog xim-coated steel coils. Galvalume steel yog tshwj xeeb tshaj yog nyiam rau nws cov superior tiv thaiv xeb piv rau galvanized steel.

Kev piav qhia

Flow daim ntawv qhia

Atxheem tawm roojyog muab rau kev thauj khoom ntau lawm, muab atsis muaj zogkev daws teeb meem uas tuaj yeem hloov kho qhov ntev thiab dav kom tau raws li cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom.

Rautrapezoidal panels ntev tshaj 6 meters, peb xav kom siv ib qhotsis siv neeg stackertxhawm rau txo qis tus nqi ua haujlwm ntawm tes thiab txhim kho kev ua haujlwm thiab kev nyab xeeb ua haujlwm. Tom qab txiav, cov panels trapezoidal raug xa mus rau lub stacker lub viav caj npab, lawv nyob qhov twgua tib zoo txheej. Tom qab ntawd, cov panels raug thauj mus rau sab nraud raws lub conveyor.

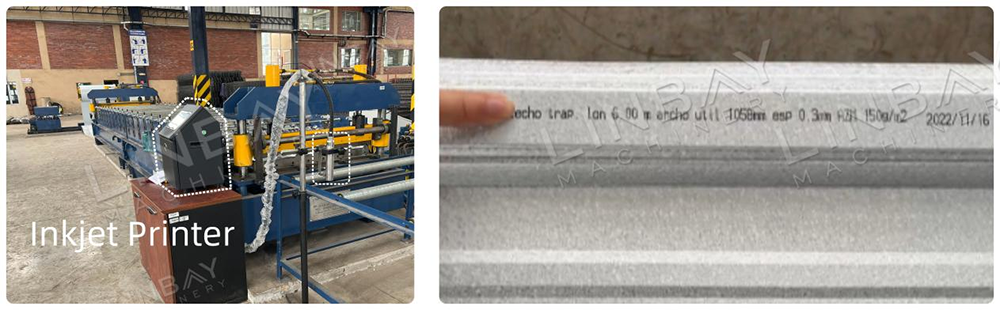

Lwm yam xaiv tau: Ink tshuab luam ntawv

Cov neeg siv khoom muaj kev xaiv los siv lub tshuab luam ntawv number case rauluam lub tuam txhab npe, logos, tus lej profile, thiab lwm yam ntaub ntawv tsim nyog rau ntawm qhov chaw ntawm cov panels.Qhov no ua kom yooj yim rau kev nthuav dav kev lag luam sai thiab nce kev pom zoo rau cov tuam txhab. Covnumber case dries sai heev thiab tsis ua rau muaj kev pheej hmoo ntawm kis kab mob.

Warranty

Ua ntej xa khoom, hnub xa khoom yog qhia rau ntawm daim ntawv teev npe, pibib tug ob-xyoo lav rau tag nrho cov ntau lawm kab thiab ib tug tsib-xyoo warranty rau rollers thiab shafts.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj