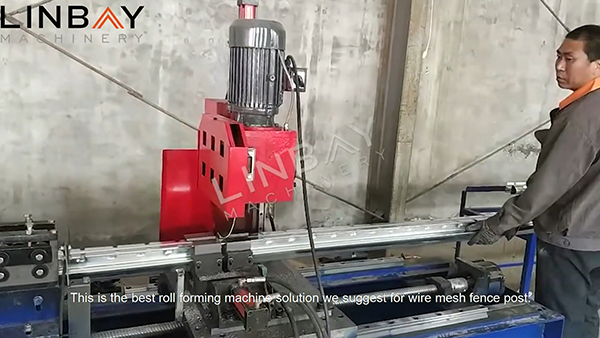

yees duab

Profile

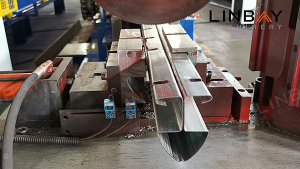

Lub laj kab laj kab laj kab, feem ntau hu ua txiv duaj ncej, khwv tau nws lub npe los ntawm nws cov duab sab nrauv zoo li lub txiv duaj. Feem ntau crafted los ntawm tsawg-carbon los yog kub dov steel coils, lub txiv duaj ncej undergoes txias dov kom ua tiav nws cov duab txawv.

Cov npoo ntawm cov hlau kauj yog khoov sab nraud los ua ib qho U-shaped nuv, txhim kho kev ruaj ntseg thaum tuav cov hlau mesh. Notch slots yog qhov chaw nyob rau ntawm ob sab ntawm lub txiv duaj ncej kom yooj yim rau kev teeb tsa ntawm cov hlau xaim mesh, nrog rau qhov loj me me kom haum rau mesh loj.

Cov kab ntau lawm suav nrog kev xuas nrig ntaus thiab yob txoj kev ua haujlwm. Cov txheej txheem rollers thiab punch tuag yog tsim los xyuas kom meej shaping thiab meej notch tso.

Cov ntaub ntawv tiag-Main Techinical Parameters

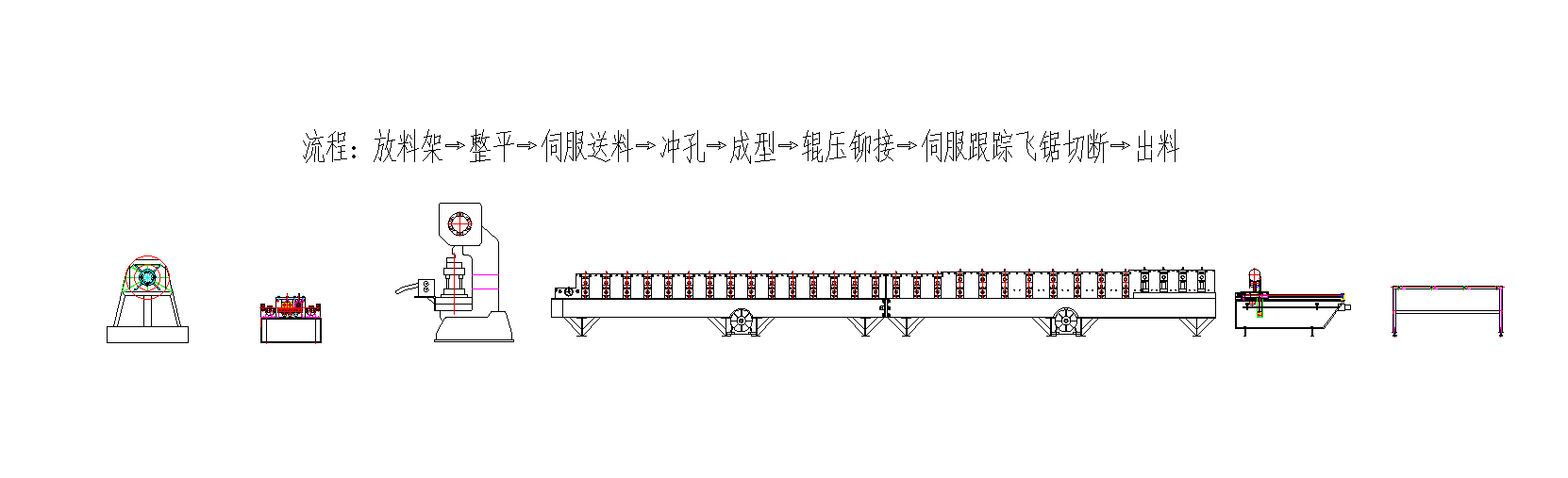

Flow daim ntawv qhia

Hydraulic decoiler-Leveler-Servo feeder-Punch xovxwm-Pit-Roll qub-Flying pom txiav-Out rooj

Main Technical Parameters:

1. Kab ceev: Kho tau los ntawm 0 mus rau 6 m / min

2. Profiles: Ib qhov loj mesh laj kab ncej

3. Khoom thickness: 0.8-1.2mm (rau daim ntawv thov no)

4. Cov ntaub ntawv tsim nyog: Kub dov steel, txias dov hlau

5. Roll forming tshuab: Phab ntsa vaj huam sib luag qauv nrog cov saw tsav tsheb

6. Tus naj npawb ntawm cov chaw tsim khoom: 26

7. Riveting system: Cov menyuam hom; yob qub tseem ua haujlwm thaum lub sij hawm riveting

8. Txiav system: Pom txiav; yob qub tseem ua haujlwm thaum txiav

9. PLC txee: Nruab nrog Siemens system

Cov ntaub ntawv tiag tiag-Kev piav qhia

Hydraulic decoiler

Lub decoiler muab versatility nrog kev xaiv rau phau ntawv, hluav taws xob, thiab hydraulic ua haujlwm. Qhov kev xaiv ntawm hom yog nyob ntawm lub coil hnyav thiab thickness kom du thiab seamless uncoiling.

Qhov no hydraulic decoiler boasts lub peev xwm loading ntawm 5 tons thiab yog outfitted nrog sab nraud coil retainers los tiv thaiv slippage. Lub cev muaj zog tsav cov cuab yeej nthuav dav, tso cai rau kev nthuav dav thiab kev cog lus kom haum rau ntau lub coil sab hauv txoj kab uas hla ntawm 460mm txog 520mm.

Leveler

Lub leveler ua tau zoo flattens lub kauj, relieving sab hauv siab thiab kev ntxhov siab, yog li txhim kho cov xuas nrig ntaus thiab tsim cov txheej txheem.

Servo feeder & Punch xovxwm

Peb lub servo feeder, tus yam ntxwv los ntawm qhov pib-nres qeeb qeeb, muaj kev tswj xyuas meej ntawm lub feeder. Qhov no ua kom muaj tseeb coil pub ntev thiab punch txoj haujlwm, txhim kho tag nrho cov khoom raug thiab ua haujlwm tau zoo.

Tiav xaim mesh laj kab ncej yog nruab nrog ntau qhov chaw tsim los rau kev sib txuas ntawm cov hlau mesh.

Roll forming tshuab

Lub tshuab yob txoj kev no yog tsim los nrog cov qauv phab ntsa thiab ua haujlwm siv cov saw hlau tsav. Thoob plaws hauv txoj kev tsim, lub kauj maj mam deforms nyob rau hauv lub zog, ua raws li cov lus teev tseg "Peach shape" tau piav qhia hauv cov duab kos.

Txhawm rau tiv thaiv kev sib cais coil ntawm qhov kev sib txuas tom qab siv txuas ntxiv, kev ntsuas kev ceev faj yog siv. Tom qab yob txoj kev, riveting rollers nias lub coil sib tshooj, tsim rivet impressions uas bolster post stability thiab nce lifespan.

Tsis tas li ntawd, vim lub voj voog tsim ntawm cov riveting rollers, cov yob qub tuaj yeem ua haujlwm txuas ntxiv mus ntxiv raws li cov kauj ruam dhau los thaum lub sij hawm riveting, tshem tawm qhov xav tau los teeb tsa lwm lub hauv paus rau lub riveting.

Flying saw txiav

Vim lub kaw lus ntawm cov txiv duaj ncej, pom txiav tawm raws li txoj kev tsim nyog tshaj plaws, tiv thaiv cov coil deformation ntawm cov npoo txiav. Ntxiv mus, cov txheej txheem txiav tsis tsim cov khoom pov tseg. Txhawm rau txhim kho cov kab ntau lawm, lub tshuab txiav lub hauv paus tuaj yeem hloov kho rov qab thiab xa mus rau synchronize nrog yob txoj kev tshuab ceev, kom ntseeg tau tias tsis muaj kev cuam tshuam.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj