yees duab

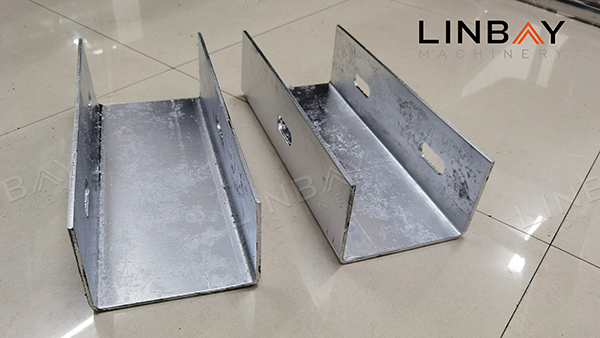

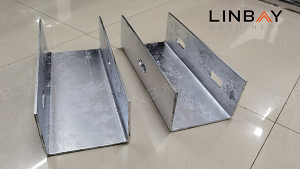

Profile

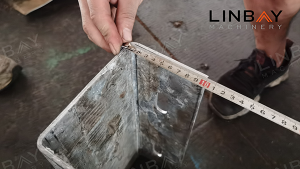

Cov profiles uas tsim los ntawm cov kab ntau lawm yog tag nrho hauv U-puab cov ntaub ntawv, tshwj xeeb tshaj yog U post thiab spacer thaiv nyob rau hauv lub guardrail system. Lub spacer thaiv ua raws li kev tiv thaiv thaiv nyob nruab nrab ntawm tus ncej thiab guardrail nqaj, muab cushioning raws li kev cuam tshuam.

Feem ntau, U posts thiab spacer blocks yog crafted los ntawm 5 hli txias-dov los yog kub dov hlau, nrog rau lub qhov punching ua ntej txheej txheem tsim. Cov qhov no yog tsim los rau cov ntsia hlau thiab ntsia hlau ntsia hlau.

Cov ntaub ntawv tiag-Main Techinical Parameters

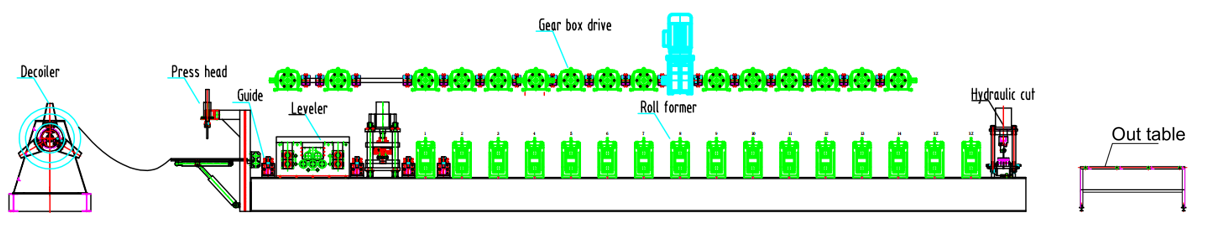

Flow daim ntawv qhia

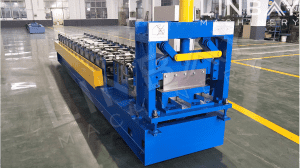

5T Hydraulic decoiler--Kev taw qhia--Leveling--Hydraulicpunch--Roll forming tshuab--Hydraulic txiav--Out rooj

Main Technical Parameters:

1. Kab ceev: Kho tau los ntawm 0 mus rau 6m / min

2. Profiles: U ncej channel thiab Spacer

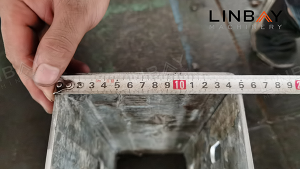

3. Khoom thickness: 5mm (rau daim ntawv thov no)

4. Cov ntaub ntawv tsim nyog: Kub dov steel, txias dov hlau

5. Roll forming tshuab: cam khwb cia-hlau qauv nrog lub gearbox tsav system

6. Tus naj npawb ntawm cov chaw tsim khoom: 16

7. Punching system: Hydraulic; yob qub nres thaum xuas nrig ntaus

8. Txiav system: Hydraulic; yob qub nres thaum txiav

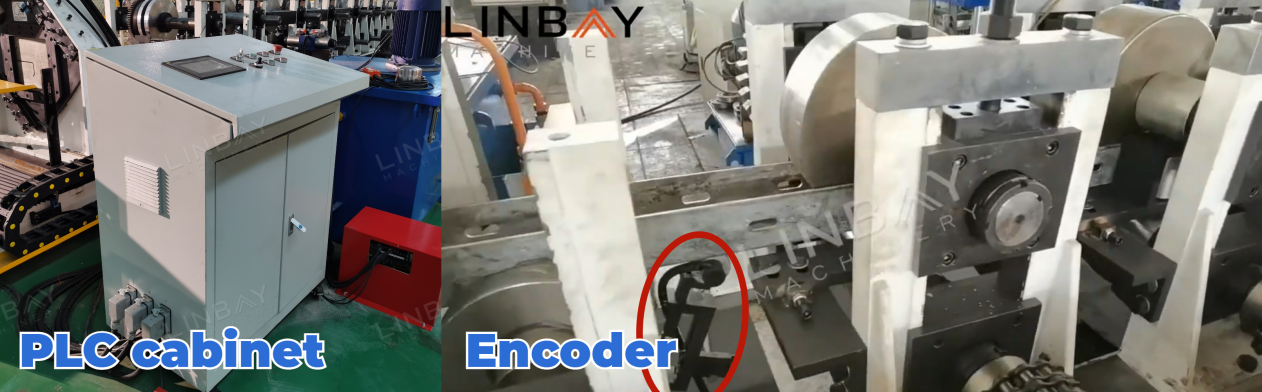

9. PLC txee: Nruab nrog Siemens system

Cov ntaub ntawv tiag tiag-Kev piav qhia

Hydraulicdecoiler

Engineered nrog ob qho tib si efficiency thiab kev nyab xeeb nyob rau hauv lub siab, lub hydraulic decoiler yog powered los ntawm ib tug robust hydraulic chaw nres tsheb. Nruab nrog cov khoom siv sab nraud, nws tiv thaiv cov hlau kauj kom tsis txhob ntog thaum ua haujlwm. Tsis tas li ntawd, cov xovxwm tuav ruaj ntseg tuav lub kauj nyob rau hauv qhov chaw, yog li ua kom cov neeg ua haujlwm muaj kev nyab xeeb los ntawm kev tiv thaiv ib qho kev npaj txhij txog caij nplooj ntoos hlav.

Leveler

Los ntawm alleviating internal stress nyob rau hauv lub coils, lub leveler optimizes lawv rau xuas nrig ntaus thiab tsim cov txheej txheem. Kev koom ua ke nrog lub hauv paus tshuab tsim, lub leveler tsis tsuas yog txhim kho kev ua tau zoo tab sis kuj txuag tau qhov chaw muaj txiaj ntsig hauv pem teb thiab txo cov nqi av hauv koj cov kab ntau lawm.

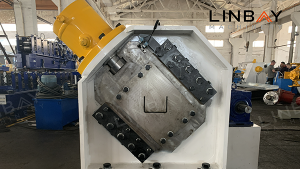

Hydraulicpunch ua

Cov punch hydraulic tuaj yeem ua tau zoo punch qhov hauv steel coils txog li 5 hli tuab, npaj lawv rau kev teeb tsa ntsia hlau. Txuas nrog yob txoj kev tshuab puag, nws lav kev ua haujlwm zoo, txawm tias yuav tsum tau ncua sijhawm luv luv thaum xuas nrig ntaus.

Rau kev txhim kho ntau lawm ceev, ib tug standalone hydraulic punch tov kuj muaj.

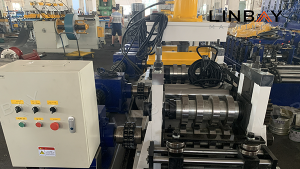

Roll uaformingmua mob

Nyob rau hauv cov tub ntxhais ntawm cov kab ntau lawm yog yob txoj kev tshuab, boasting ib tug cam khwb cia hlau qauv muaj peev xwm ntawm effortlessly tuav 5 hli tuab steel coil txoj kev. Tag nrho cov yob txoj kev yob yog powered los ntawm lub gearbox system thiab crafted los ntawm Gcr15, ib tug high-carbon chromium-cov kabmob steel, muab tshwj xeeb hardness thiab hnav tsis kam, ntxiv augmented los ntawm chrome plating. Tsis tas li ntawd, cov cua kub-kho 40Cr shafts kom ruaj khov thiab kev ntseeg tau txawm tias nyob rau hauv cov kev xav tau tshaj plaws.

Encoder & PLC

Precision thiab tswj yog seamlessly kev koom ua ke nrog lub encoder thiab PLC system. Hloov steel kauj ntev mus rau hauv cov teeb liab hluav taws xob, tus encoder muab cov lus qhia tseeb rau PLC tswj txee. Tsis muaj xws li ntau lawm ceev, ntau npaum li cas ib lub voj voog, thiab txiav ntev tuaj yeem raug teeb tsa ntawm PLC tswj txee, kom ntseeg tau tias kev txiav tsis raug txwv tsis pub dhau.±1 hli. Cov neeg siv khoom tuaj yeem teeb tsa qhov ntev raws li lawv cov kev xav tau los ntawm kev ua haujlwm vaj huam sib luag.

Hydrauliccut

Txhua qhov txiav yields du, burr-dawb npoo, tshem tawm cov khib nyiab thiab ua kom ntseeg tau tias tsis muaj tseeb, uas thaum kawg txuag cov nqi rau cov neeg siv khoom. Nws yog ib qho tsim nyog sau cia tias yob txoj kev tshuab nres thaum txhua qhov kev ua haujlwm txiav.

Peb kuj muab cov kev daws teeb meem siab dua qhov twg cov yob txoj kev tshuab tsis nres thaum txiav, yog tias koj xav tau.

Hydraulicskev ua haujlwm

Kev ua tau zoo ua ke nrog kev ntseeg tau los ntawm peb qhov chaw nres tsheb hydraulic. Featuring cua txias hluav taws xob kiv cua, nws zoo dissipates tshav kub, txhawb kev pom kev ua haujlwm kub rau kev ua haujlwm ntev. Nrog tsawg tsis ua hauj lwm tus nqi, peb cov chaw nres tsheb hydraulic kom durability thiab ntev, guaranteeing uninterrupted ntau lawm workflows.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj