yees duab

Profile

Hla bracing plays lub luag haujlwm tseem ceeb hauv cov kab ke khib nyiab, txhawb kev txhawb nqa thiab kev ruaj ntseg ntawm ob txoj kab ncaj nraim. Crafted los ntawm cov hlau dub ruaj khov nrog cov tuab feem ntau yog li ntawm 1.5 txog 2.5mm, tom qab tsim cov xim pleev xim rau kev txhim kho corrosion thiab xeb tsis kam, ua kom lub neej ntev thiab kev ntseeg tau.

Cov ntaub ntawv tiag-Main Technical Parameters

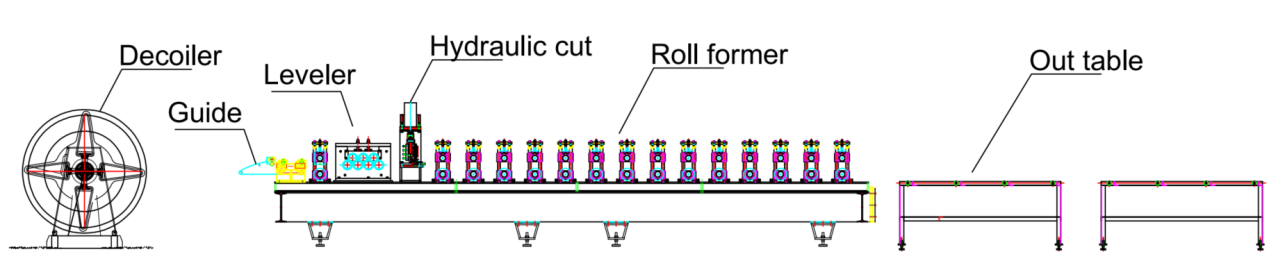

Flow chart: Decoiler--Cov lus qhia--Leveler--Pre txiav--Roll daim ntawvhauv tshuab-- Tawm rooj

- 1.Line ceev: 0-15m / min, adjustable

- 2.Dimensions nyob rau hauv cov ntaub ntawv tiag tiag: Ntau qhov dav 80-300mm, ruaj siab 50mm

- 3.Suitable khoom: Galvanized steel

- 4.Material thickness: 1.5-2mm

- 5.Roll forming tshuab: Cast-iron qauv thiab chain tsav system

- 6.Cutting system: Txiav ua ntej yob txoj kev tshuab, nrog lub zog hydraulic.

- 7.PLC txee: Siemens system.

Cov ntaub ntawv tiag-Machinery

1.Decoiler * 1

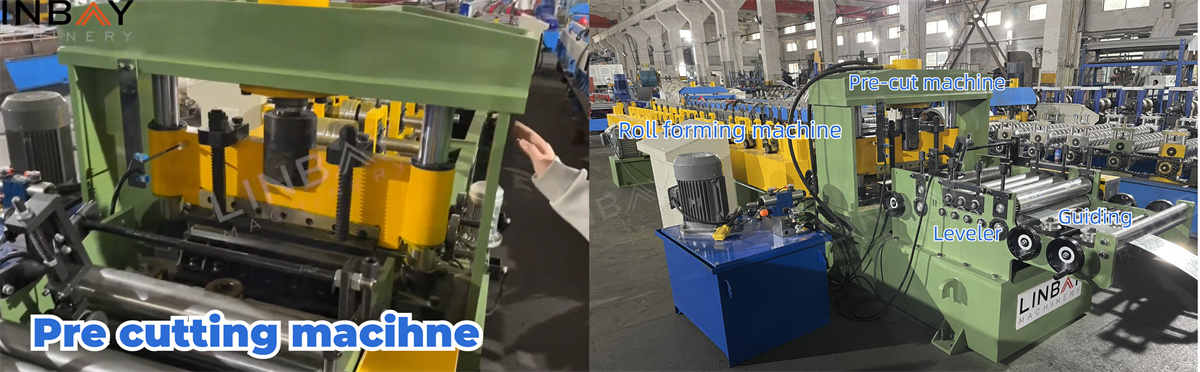

2.Leveler (Nruab ntawm lub yob txoj kev tshuab) * 1

3.Hydraulic ua ntej txiav tshuab * 1

4. Roll forming tshuab * 1

5.Out rooj * 2

6.PLC tswj txee * 1

7.Hydraulic chaw nres tsheb * 2

8. Cov khoom seem lub thawv (Dawb) * 1

Cov ntaub ntawv tiag tiag-Kev piav qhia

- Decoiler

Feem ntau, lub decoiler yog thawj feem ntawm cov kab ntau lawm. Nws lub caj npab xovxwm muaj peev xwm ua kom ruaj khov steel kauj, tiv thaiv kev raug mob los ntawm coil recoil thaum hloov coil. Outward coil retainer li ntxiv tiv thaiv coils los ntawm zawv zawg tawm ntawm mandrel.

Kev taw qhia

Cov guiding rollers yuav coj cov hlau kauj kom zoo rau hauv cov txheej txheem ua kom cov kev sib raug zoo ntawm cov hlau kauj thiab cov yob txoj kev tshuab, txo qhov muaj peev xwm khoov lossis sib txawv.

Leveler

Lub thickness ntawm tus ntoo khaub lig bracing ncav cuag 2.5 hli, thiab tsuas yog thaum nws yog zoo meej ncaj thiab tsis twisted nws yuav muab qhov zoo tshaj plaws stability rau lub khib thav duab. Lub tshuab leveling tuaj yeem flatten steel kauj, tso tawm sab hauv siab, ua kom yooj yim rau cov duab thiab tsim ncaj. Nyob rau hauv no ntau lawm kab, lub leveling tshuab yog teem rau yob txoj kev tshuab puag, uas yuav txuag tau nyob rau hauv pem teb thiab txo nqi av.

Pre-txiav tshuab

Piv nrog rau kev txiav tom qab txiav, pre-txiav ua ntej sib sau ua tsis muaj pov tseg. Qhov kev daws teeb meem no yooj yim dua hloov cov hlau coils ntawm qhov sib txawv ntawm qhov dav rau kev tsim ntau qhov ntau thiab tsawg ntawm tib cov kab ntau lawm, tsis ua rau muaj kev pov tseg.

Roll daim ntawvhauv tshuab

Roll forming tshuab yog qhov tseem ceeb tshaj plaws ntawm tag nrho cov kab ntau lawm. Nws siv lub zog cam khwb cia-hlau kev tsim kho rau qhov chaw nres tsheb, ua los ntawm cov khoom siv hlau. Kev sib hloov ntawm cov txheej txheem yob yog tsav los ntawm cov saw hlau.

Cov khoom ntawm kev sib sau chais yog Gcr15, high-carbon chromium bearing steel renowned rau nws zoo heev hardness thiab hnav tsis kam. Cov rollers yog chrome-plated kom ntev lawv cov kev pab cuam lub neej. Cov shafts yog ua los ntawm 40Cr cov ntaub ntawv thiab tau txais kev kho cua sov.

Reinforcements tau muab tso rau hauv qab ntawm qhov profile los txhim kho nws lub zog. Qhov no yob txoj kev tshuab tuaj yeem tsim kev sib tsoo nrog qhov dav ntawm 80-300mm thiab qhov siab ntawm 50mm. Los ntawm kev nkag mus rau qhov xav tau qhov ntev rau hauv PLC tswj vaj huam sib luag, qhov chaw tsim khoom txav raws cov ntsia hlau mus rau qhov tseeb thiab meej. Lub ntsiab lus tseem ceeb kuj kho raws li qhov chaw tsim khoom txav mus.

Rau kev nyab xeeb ntawm kev txav ntawm cov chaw tsim khoom, 2 nrug sensors yog teem rau ntawm lub tshuab puag, sib xws rau cov hauj lwm sab nraud thiab innermost uas covtsimchaw nres tshebstuaj yeem txav mus rau.Rau cov sensors, tnws sensing point yog tusntawm nontawmlub hauv paus ntawm cov chaw tsim khoom. Sab hauvsensoryog los tiv thaiv covtsimchaw nres tshebslos ze heev thiab ua rau cov menyuam sib tsoo.Sab nraudsensoryog los tiv thaiv covtsimchaw nres tsheb los ntawm disengaging los ntawm lubtxoj hluathiab poob.

Chaw nres tsheb Hydraulic

Lub chaw nres tsheb hydraulic tuaj nrog cov kiv cua txias tsim los ua kom muaj cua sov kom zoo, lav kev ua haujlwm tsis cuam tshuam thiab txhawb kev tsim khoom. Renowned rau nws qhov tsis ua hauj lwm tus nqi qis, qhov chaw nres tsheb hydraulic no yog tsim los kom kav ntev, ua kom lub sijhawm ntev.

PLC tswj txee & Encoder

Lub encoder hloov lub siab ntev ntawm steel kauj mus rau hauv hluav taws xob cov cim xa mus rau PLC tswj txee. Tsis pub dhau lub txee tswj, ntau lawm ceev, ib tus neeg cov khoom tsim tawm, txiav ntev, thiab lwm yam tuaj yeem tswj tau. Nrog cov kev ntsuas meej thiab cov lus tawm tswv yim los ntawm tus encoder, lub tshuab txiav tuaj yeem tswj cov kev txiav txim tsis pub dhau ± 1 hli.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj