VIDEO

Perfil

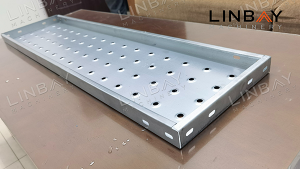

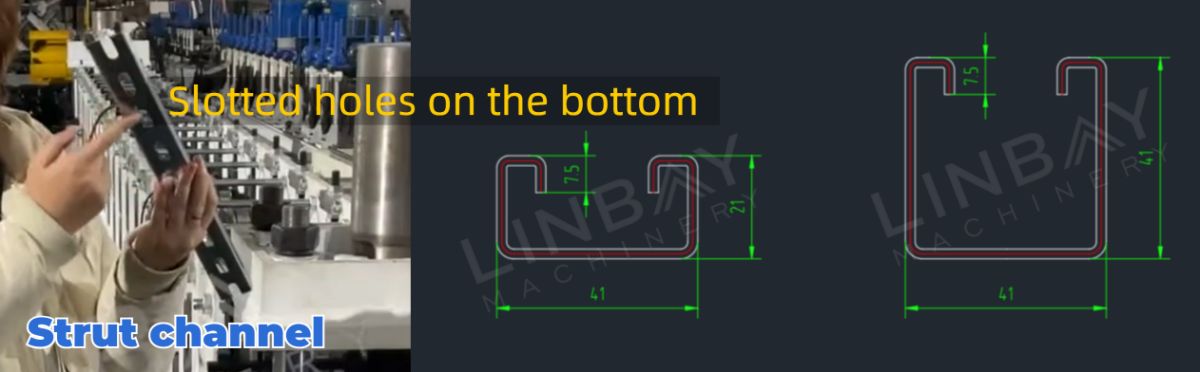

Strut channel ua haujlwm tseem ceeb hauv kev txhawb nqa thiab sib txuas cov khoom siv hauv tsev hauv kev tsim kho. Tus qauv qhov ntev rau strut channel feem ntau suav nrog41 * 21mmthiab41 * 41mm. Cov channel no feem ntau yog tsim los ntawm cov khoom xws likub dov hlau, txias dov hlau, los yog galvanized steel, featuring ib thickness feem ntau xws li los ntawm1.5mm txog 2mm.

Cov ntaub ntawv tiag-Main Techinical Parameters

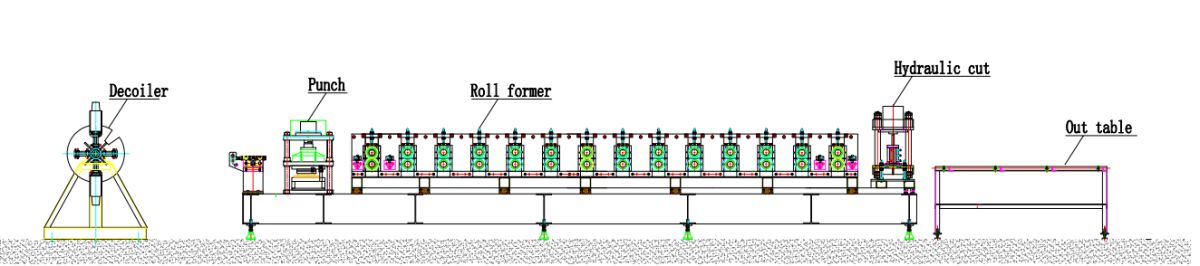

Flow daim ntawv qhia

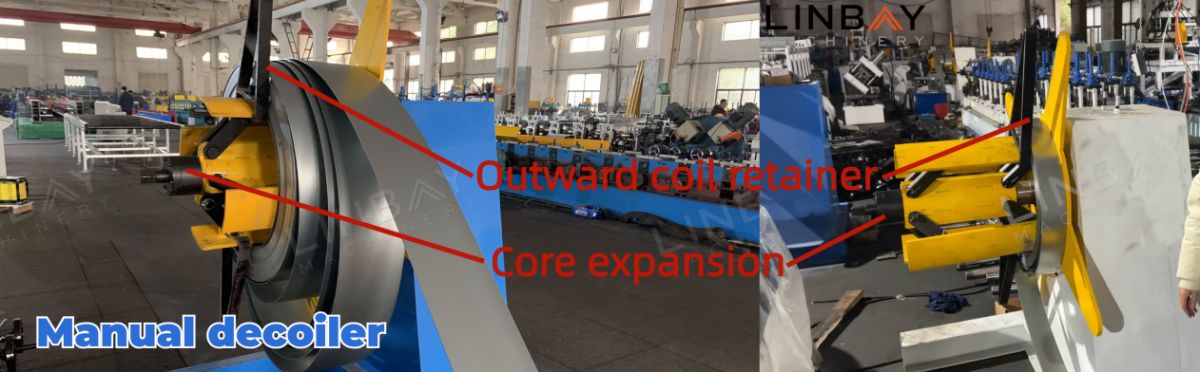

Cov phau ntawv decoiler yog nruab nrog lub tshuab nres, tso cai rau kev hloov pauv tseem ceeb ntawm φ490-510 mm,kom ntseeg tau tias du uncoiling. Tsis tas li ntawd, ib qho khoom siv sab nraud tiv thaiv coil slippage, boosting cost-effectiveness thiab kev nyab xeeb. Nyob rau hauv cov ntaub ntawv ntawm hydraulic decoiler, ib tug xovxwm caj npab ruaj lub steel kauj, mitigating qhov kev pheej hmoo ntawm coil caij nplooj ntoos hlav-up thiab tej zaum cov neeg ua hauj lwm raug mob. Txhawm rau ua kom tau raws li qhov xav tau ntau ntxiv, peb muab cov kev xaiv hydraulic decoiler siv los ntawm qhov chaw nres tsheb hydraulic.

Kev tuav decoiler--Guiding--Hydraulic punch--Roll forming tshuab--Hydraulic txiav--Out rooj

Main Techinical Parameters

1.Line ceev: 0-12m / min tsis muaj xuas nrig ntaus, 3m / min nrog xuas nrig ntaus.

2.Material thickness: 2 hli nyob rau hauv cov ntaub ntawv no.

3.Suitable khoom: Kub dov hlau, txias dov hlau, galvanized steel.

4.Roll forming tshuab: Phab ntsa vaj huam sib luag qauv thiab saw tsav tsheb.

5. Tsis muaj. Qhov chaw nres tsheb: 20

6.Punching system: Hydraulic, yob qub nres thaum xuas nrig ntaus.

7.Cutting system: Hydraulic, yob qub nres thaum txiav.

8. Hloov loj: 2-3 teev manually.

9.PLC txee: Siemens system.

Cov ntaub ntawv tiag tiag-Kev piav qhia

Phau ntawv decoiler

Kev taw qhia

Kev taw qhia rollers ua lub luag haujlwm tseem ceeb hauv kev tswj xyuas kev sib raug zoo ntawm cov hlau kauj thiab lub tshuab, tiv thaiv kev cuam tshuam ntawm cov strut channel.

Kev taw qhia rollers ua lub luag haujlwm tseem ceeb hauv kev tsim cov txheej txheem, tiv thaiv rov qab deformation ntawm cov sawb hlau. Qhov ncaj ntawm lub raj nqaj yog qhov tseem ceeb rau cov khoom lag luam zoo, cuam tshuam rau kev txhawb nqa kev ua haujlwm ntawm tag nrho cov txheej txheem installation. Kev taw qhia chais yog qhov kev teeb tsa raws li tag nrho cov yob txoj kev tshuab, tsis yog ntawm qhov nkag. Ua ntej ua zaub mov xa tuaj, peb ntsuas qhov kev ncua deb ntawm txhua qhov kev taw qhia rau lub tshuab ntug thiab sau cov kev ntsuas no hauv phau ntawv. Thaum muaj kev hloov pauv me ntsis thaum lub sijhawm thauj mus los lossis cov txheej txheem tsim khoom, cov neeg ua haujlwm tuaj yeem siv cov ntaub ntawv sau tseg no los hloov cov chais kom raug.

Hydraulic Punch

Lub tshuab xuas nrig ntaus, siv los ntawm qhov chaw nres tsheb hydraulic, nyob rau pem hauv ntej ntawm lub tshuab yob txoj kev, yuav tsum tau ncua ib ntus hauv cov txheej txheem yob txoj kev thaum xuas nrig ntaus. Lub tshuab xuas nrig ntaus hydraulic tau teeb tsa nrog lub punch kauj ruam ntawm 400 hli. Rau kev ua kom nrawm nrawm, peb xav kom muaj kev ywj pheej hydraulic xuas nrig ntaus cov kev daws teeb meem raws li cov ntawv xuas nrig ntaus.

Roll Forming Tshuab

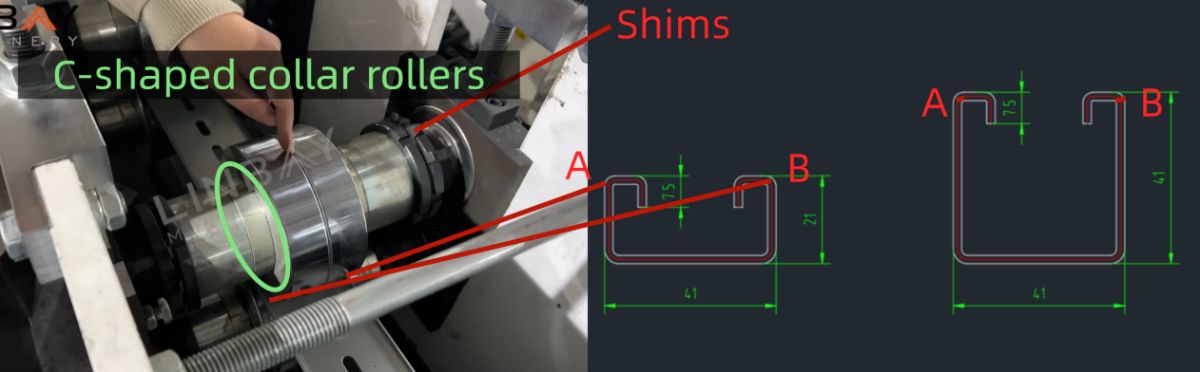

Lub tshuab yob txoj kev ua haujlwm nta lub phab ntsa vaj huam sib luag thiab cov saw-tsav tsheb, muab cov kev daws teeb meem zoo rau kev hloov pauv loj nrog lub sijhawm hloov ntawm txog2-3 teev.

Kho cov ntsiab lus tsim yog qhov tseem ceeb rau kev hloov qhov ntau thiab tsawg. Loosening lub shims ntawm qhov kawg ntawm cov chais thiab hloov los yog ntxivC-shaped dab tshos rollers (lub tes tsho)ntawm qhov tsim nyog txoj hauj lwm hloov qhov tsim taw tes rau qhov tshiab profile loj. Tsis tas li ntawd, peb muab ib qhotsis siv neeg loj hloov dawsnrog lub sijhawm hloov ntawmkwv yees li 10 feeb.

Video link to -【Kev teeb tsa】Linbay Hloov lub tes tsho rau yob txoj kev tshuab

Hydraulic txiav

Lub tshuab txiav hydraulic, ua haujlwm los ntawm qhov chaw nres tsheb hydraulic, muaj peev xwm txiav 2 hli tuab steel coils. Nws cov hniav txiav yog ua raws li cov duab profile, ua ib ncig ntawm 8 hli ntawm cov khoom pov tseg ib ntus thaum tuav ib qho ze li ntawm qhov tsis muaj qhov txiav.

Encoder & PLC

Lub tshuab yob txoj kev sib txuas ua ke nrog Japanese hom Koyo encoder, uas txhais cov coil lengths rau hauv cov teeb liab hluav taws xob xa mus rau PLC tswj txee. Cov txheej txheem meej no ua kom ntseeg tau tias kev txiav tsis raugnyob rau hauv qhov ntau ntawm ± 1mm, xyuas kom muaj cov khoom lag luam zoo thaum txo cov khoom pov tseg los ntawm kev txiav tsis raug. Cov neeg ua haujlwm tuaj yeem tswj tau qhov nrawm nrawm, qhov ntev ntawm cov khoom, txiav ntev, thiab ntau dua los ntawm PLC screen. Tsis tas li ntawd, PLC tswj txee ntanco ciarau feem ntau siv tsis tau thiab muab kev tiv thaiv zog xws li overload, luv luv Circuit Court, thiab theem poob.

Cov lus ntawm PLC npo tuaj yeem hloov kho raws li cov neeg siv khoom nyiam.

Chaw nres tsheb Hydraulic

Peb qhov chaw nres tsheb hydraulic yog nruab nrog cov cua txias hluav taws xob kom ua kom cov cua sov kom zoo, ua kom muaj kev ua haujlwm ntev thiab txhim khu kev qha nrog tus nqi qis qis, yoog rau qhov chaw ua haujlwm kub.

Warranty

Nyob rau hnub ntawm cov khoom xa tuaj, hnub tam sim no yuav raug kos rau ntawm daim ntawv hlau, kos npe rau qhov pib ntawm ob xyoos lav rau tag nrho cov kab ntau lawm thiab tsib xyoos lav rau cov menyuam thiab cov ncej.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj