yees duab

Profile

Gutter:Hlau gutters feem ntau yog siv rau cov dej ntws raws cov npoo ntawm lub tsev ru tsev, feem ntau los sau cov dej nag. Cov qauv muaj xws lihalf-puag ncighomthiab K-stylehom. Lawv feem ntau yog ua los ntawm cov ntaub ntawv hlau xws li 0.3-0.8mm, xws li aluminium, pre-painted steel, los yog galvanized steel.

Ridge Cap:Lub qaumcapyogteebqhov twg ob sab ntawmoblub ru tsevvaj huam sib luagntsib, tseem hu ua lub ru tsevsaum. Nws yog feem ntausivd los txhim kho kev sib khi thiab kev zoo nkauj ntawm lub ru tsev. Ridge caps feem ntau yog ua los ntawm cov hlau ua ntej pleev xim los yog galvanized steel li ntawm 0.3-0.8mm.

Cov ntaub ntawv tiag-Main Technical Parameters

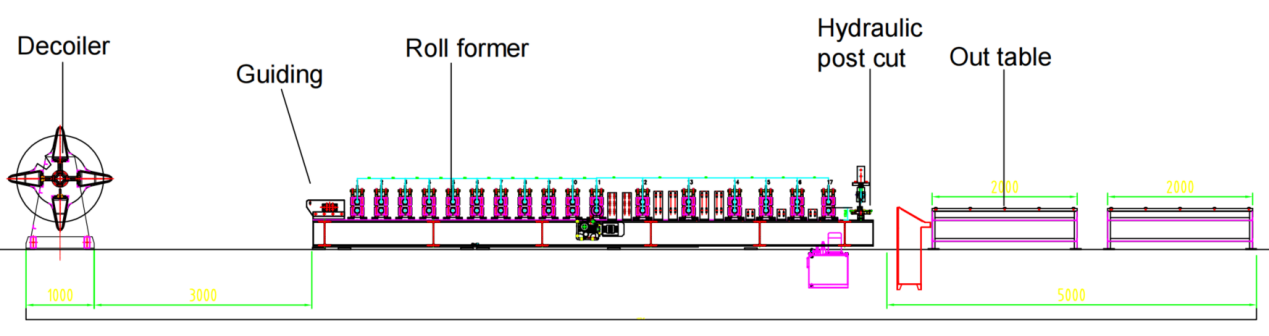

Flow chart: Decoiler--Guiding--Roll forming tshuab--Hydraulic cut--Out rooj

- 1.Ridge cap-Line ceev: 0-12m / min, adjustable

- 2.Gutter-Line ceev: 0-4m / min, adjustable

- 3. SuavCov khoom siv rooj: Galvanized steel, pre-painted steel, aluminium

- 4.Material thickness: 0.3-0.8mm

- 5.Roll forming tshuab: Phab ntsa vaj huam sib luag qauv thiab saw tsav tsheb

- 6.Cutting system: nres txiav tom qab yob txoj kev tshuab, yob qub nres thaum txiav.

- 7.PLC txee: Siemens system.

Cov ntaub ntawv tiag-Packing List

- 1.Hydraulic decoiler * 2

- 2.Double-kab yob txoj kev tshuab * 1

- 3.Ob-kab hydraulic txiav tshuab * 1

- 4.Out table*2

- 5.PLC tswj txee * 1

- 6.Hydraulic chaw nres tsheb * 1

- 7.Cov khoom seem lub thawv (Dawb)

Cov ntaub ntawv tiag tiag-Kev piav qhia

- Decoiler

Rau ridge cap thiab gutter, configuration ntawm lub decoiler yog ze li qub, siv hydraulic decoilers nrog lub peev xwm ntawm 3 tons txhua. Muab qhov dav sib txawv ntawm cov hlau coils siv rau ridge cap thiab gutter, nws yog qhov zoo dua los faib cov decoiler rau txhua kab ntau lawm. Txoj hauv kev no txo qis qis qis thaum lub sijhawm hloov coil thiab txhim kho kev ua haujlwm zoo rau txhua txoj kab ntau lawm.

Kev taw qhia

Covguiding rollers xyuas kom zoo sib xws ntawm cov hlau kauj thiab cov yob txoj kevtshuab, tiv thaiv distortion thaum lub sij hawm tsim txheej txheem.

Roll forming tshuab

Qhov no yob txoj kev tshuab siv cov phab ntsa vaj huam sib luag thiab cov saw tsav tsheb. Tsis zoo li cov qauv kev teeb tsa dual-kab uas muaj ob qhov sib txawv ntawm tib qhov profile, lub tshuab no ua haujlwm sib txawv ntawm txhua kab.

Nws yog ib qho tseem ceeb kom nco ntsoov tias ob kab tsis tuaj yeem ua haujlwm ib txhij. Peb pom zoo kom muab cov kab ntau lawm cais rau txhua qhov profile yog tias koj xav tau ntau dua.

Tsis tas li ntawd, cov hlau npog tau raug ntsia rau ntawm cov saw hlau los tiv thaiv cov neeg ua haujlwm los ntawm kev sib cuag nrog cov saw hlau thiab tiv thaiv cov saw hlau tiv thaiv kev puas tsuaj los ntawm cov plua plav thiab cov khib nyiab.

Hydraulic txiav

Cov tshuab txiav yog tsau rau ntawm cov kab ntau lawm, nres qhov txav ntawm cov hlau kauj thaum txiav. Rau cov neeg siv khoom xav tau ntau dua kev ceev, peb muab lub tshuab txiav ya uas lub hauv paus tuaj yeem ua kom yooj yim traverse rau pem hauv ntej thiab rov qab ntawm txoj hlua ntawm tib qhov ceev ntawm yob txoj kev tshuab. Qhov kev tsim kho tshiab no ua rau cov hlau kauj ua tau zoo los ntawm kev tsim tshuab yam tsis muaj kev cuam tshuam thaum txiav, yog li ua kom muaj txiaj ntsig zoo ntawm cov kab ntau lawm.

Thaum kawg ntawm ob kab, cov hniav txiav yog meticulously crafted kom precisely phim cov contours ntawm cov profiles. Qhov no ua kom ntseeg tau tias cov npoo ntawm cov profiles yog undistorted, tswj cov txheej txheem siab tshaj plaws ntawm precision thiab zoo.

Chaw nres tsheb Hydraulic

Muab lub zog thawj zaug rau lub cuter los ntawm lub tank kaw. Nws yog tawm yam tsis tau txiav, uas tuaj yeem txuag lub zog.

Lub chaw nres tsheb hydraulic yog nruab nrog cov kiv cua txias, ua kom muaj txiaj ntsig zoo ntawm cov cua sov kom ntseeg tau tias lub sijhawm ntev thiab kev ua haujlwm zoo. Nrog rau tus nqi qis tsis ua haujlwm thiab kev ua haujlwm tshwj xeeb, qhov chaw nres tsheb hydraulic lav kev ua haujlwm tau zoo nyob rau lub sijhawm ntev.

PLC tswj txee & Encoder

Roll forming ntau lawm kab yog quipped nrog tus encoder daim ntawv Japanese hom KOYO. Lub encoder khaws txhais qhov ntev ntawm cov hlau coils mus rau hauv cov teeb liab hluav taws xob, xa mus rau PLC tswj txee. Cov neeg ua haujlwm tuaj yeem kho qhov ceev, kom muaj nuj nqis, thiab txiav qhov ntev. Lub tshuab txiav ua tiav qhov tseeb zoo kawg nkaus ua tsaug rau tus encoder qhov kev ntsuas qhov tseeb thiab cov lus tawm tswv yim, ua kom txiav qhov yuam kev hauv ± 1 hli.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj