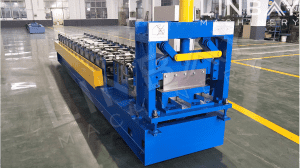

yees duab

Profile

TR 80 yog ib qho qauv tsim ntawm hauv pem teb decking. Nyob rau hauv rooj plaub no, 1 hli tuab 350MPA high-strength steel kauj yog siv.

Kev piav qhia

Flow daim ntawv qhia

Hydraulic decoiler-Guiding thiab pub-Embossing ib feem- Siliting ntaus ntawv-Roll txoj kev tshuab

Hydraulic Decoiler

Peb nruab ib lub siab caj npab ntawm lub decoiler kom ruaj khov steel kauj nyob rau hauv qhov chaw thaum lub sij hawm hloov coil, tiv thaiv kev tso tawm sai sai thiab muaj peev xwm ua rau cov neeg ua haujlwm raug mob. Tsis tas li ntawd, steel tiv thaiv hniav yog ntsia los tiv thaiv coil slippage thaum lub sij hawm decoiling txheej txheem. Qhov kev tsim no tsis tsuas yog tiv thaiv cov hlau kauj thiab lub tshuab xwb tab sis kuj ua kom cov neeg ua haujlwm muaj kev nyab xeeb.

Kev taw qhia&Embossing Part

Cov tuav tuav tswj kev sib raug zoo ntawm cov hlau kauj thiab lub tshuab, kom ntseeg tau qhov profile qhov ncaj. Thoob plaws hauv tag nrho txoj kab kev tsim, ntau cov kev taw qhia rollers tau muab tso rau hauv kev txhim kho precision.

Feem ntau, embossing yog nyob ib ncig ntawm 2 hli sib sib zog nqus, tab sis hauv qhov kev daws teeb meem no peb tau nce nws mus4 mm rau cov qauv kom pom tseeb thiab nthuav tawm ntau dua.

Slitting Device& Cov khoom siv khib nyiab

Ua ntej cov hlau kauj nkag mus rau hauv cov txheej txheem, nws ntsib cov khoom siv slitting ntawm sab laug. Raws li qhov dav ntawm coils yuav los ntawm steel zebfeem ntau yog nyob ze tab sis tsis yog qhov dav pub mis ntawm qhov profile no, cov cuab yeej no pab txiav thiab sau cov dav dav,txuag cov nuj nqisntawm coil slitting ntawm steel zeb.

Roll Forming Tshuab

Qhov no yob txoj kev tshuab siv lub phab ntsa vaj huam sib luag qauv thiab saw-tsav system. Vim lub steel coil lub zog ncav cuag 350MPA, qhov kev sib sau ceev yog me ntsis txo los cuam tshuam nrog kev ua haujlwm nyuaj. Lub kauj dhau los ntawm tag nrho ntawm 33 txheej ntawm yob txoj kev chaw nres tsheb, thaum kawg tsim cov hlau lawj profile ntawm cov neeg siv khoom kos duab.

Hydraulic Tej Tshuab&PLC

Lub tshuab txiav no tsim tawm kwv yees li 8 hli ntawm cov khib nyiab ib ntus, tab sis nrog tsawg kawg burrs ntawm cov npoo txiav. Cov neeg ua haujlwm tuaj yeem tswj hwm qhov nrawm, teeb tsa qhov ntev, txiav qhov ntev, thiab ntau dua los ntawm PLC screen. Lub encoder raws cov kab ntau lawm converts sensed steel coil lengths rau hauv hluav taws xob signals, tso cai rau lub txiav tshuab tswjtxiav yuam kev hauv 1 hli, xyuas kom cov khoom zoo thiab txo cov khoom pov tseg los ntawm kev txiav tsis raug.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj