PROFILE

Lub pas dej hlau ua haujlwm ua ib qho tseem ceeb ntawm cov dej ntws los ntawm cov npoo ntawm lub ru tsev kom ntes thiab coj cov dej nag kom deb ntawm cov qauv, pab tiv thaiv kev puas tsuaj ntawm dej. Gutters feem ntau yog tsim los ntawm cov ntaub ntawv xws li txhuas, galvanized steel, xim-coated steel, tooj liab, thiab galvalume, nrog thicknesses li ntawm 0.4 thiab 0.6 hli.

Cov kab ntau lawm no muaj cov qauv ob-kab, tso cai rau kev tsim khoom ntawm ob qhov sib txawv ntawm qhov sib txawv ntawm tib kab, tab sis tsis yog tib lub sijhawm. Qhov kev tsim no optimizes qhov chaw siv thiab txo cov nqi tshuab rau cov neeg siv khoom.

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

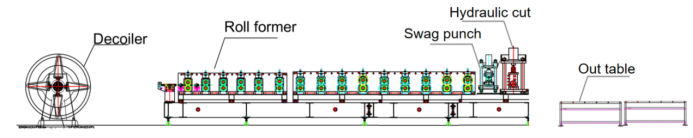

Flow chart: Decoiler--Guiding--Roll qub--Swag xuas nrig ntaus--Hydraulic txiav--Out rooj

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

· Kab CeevAdjustable: 0-12m / min.

· Cov khoom siv sib xws: Aluminium, galvanized steel, xim-coated steel, galvalume, tooj liab.

· Khoom ThicknessLoj: 0.4-0.6mm.

· Roll Forming Tshuab: Ob chav kab tsim nrog cov phab ntsa vaj huam sib luag.

· Tsav System: Chain-driven system.

· Txiav System: Nres-thiab-txiav txoj kev, qhov twg cov yob qub pauses thaum txiav.

· PLC tswj: Siemens system.

TSEEM CEEB-MACHINERY

1.Hydraulic decoiler * 1

2. Roll forming tshuab * 1

3.Hydraulic swag punch tshuab * 1

4.Hydraulic tej tshuab * 1

5.Out table*2

6.PLC tswj txee * 1

7.Hydraulic chaw nres tsheb * 2

8. Cov khoom seem lub thawv (Dawb) * 1

TSEEM CEEB-DESCRIPTION

Hydraulic Decoiler

· Ncej: Lub thav duab ruaj khov yog tsim los txhawb kev txhawb nqa steel coils, nrog rau hydraulic-powered decoiler uas boosts efficiency thiab kev nyab xeeb thaum coil pub rau hauv cov kab ntau lawm.

· Core Expansion Mechanism: Lub hydraulic-driven mandrel (los yog arbor) kho kom haum rau steel coils nrog puab diameters ntawm 490-510mm, ruaj lub kauj kom du thiab khov kho uncoiling.

· Nias Arm: Lub hydraulic xovxwm caj npab ua kom lub kauj nyob hauv txoj hauj lwm, txo qhov kev pheej hmoo ntawm kev rov qab sai vim muaj kev ntxhov siab sab hauv thiab tiv thaiv cov neeg ua haujlwm kev nyab xeeb.

· Coil Retainer: Kev ruaj ntseg rau lub mandrel hniav nrog cov ntsia hlau thiab cov txiv ntseej, cov coil retainer khaws cov hlau kauj kom tsis txhob plam tawm, thiab yooj yim rau nruab lossis tshem tawm raws li xav tau.

· Tswj System: Nruab nrog PLC thiab tswj vaj huam sib luag uas suav nrog lub khawm nres thaum muaj xwm ceev, ua kom muaj kev nyab xeeb ntawm kev ua haujlwm.

·Decoiler Options rau Dual-Low Roll Forming: Rau ob-kab yob txoj kev tshuab, ib leeg-ncej decoiler tuaj yeem siv thiab hloov kho kom txuag nqi, txawm tias nws yuav tsum tau siv sijhawm ntau dua. Xwb, ob lub taub hau ib leeg los yog ob-ncej decoiler tuaj yeem siv rau kev tsim khoom ntau dua.

Kev Taw Qhia Bars

· Kev sib tw: Xyuas kom meej tias cov hlau kauj yog nruab nrog lub tshuab axis, tiv thaiv cov teeb meem pub noj uas tuaj yeem ua rau kev sib tw, khoov, burrs, lossis qhov tsis raug ntawm qhov khoom tiav.

· Kev ruaj ntseg: Kev ruaj khov ntawm cov khoom siv yog qhov tseem ceeb, nrog cov tuav tuav kom ntseeg tau tias cov khoom noj zoo ib yam, uas yog qhov tseem ceeb rau kev tsim cov khoom ua tau zoo.

· Kev taw qhia: Lawv coj cov khoom zoo mus rau qhov pib ntawm kev sib sau cov menyuam, uas yog qhov tseem ceeb rau qhov tseeb qhov pib shaping.

· Kev tu: Nws yog ib qho tseem ceeb uas yuav tsum tsis tu ncua cov khoom siv coj los ntsuas, tshwj xeeb tshaj yog tom qab thauj lossis siv txuas ntxiv. Ua ntej xa tawm, Linbay sau cov lus qhia dav hauv phau ntawv siv, tso cai rau kev ntsuas qhov tseeb thaum tus neeg siv khoom tau txais cov khoom siv.

Roll forming tshuab

· Nqi-zoo rau Gutter Manufacturing: Sib txuas cov phab ntsa vaj huam sib luag tsim nrog cov saw-tsav system.

· Versatility rau ntau qhov ntau thiab tsawg: Kev teeb tsa dual-kab txhawb kev tsim tawm ntawm ob qhov sib txawv gutter qhov ntau thiab tsawg, optimizing qhov chaw thiab txo cov nqi siv tshuab.

· Kev tiv thaiv saw: Cov chains raug kaw nyob rau hauv ib lub casing hlau, ua kom cov neeg ua haujlwm muaj kev nyab xeeb thiab tiv thaiv cov chains los ntawm kev puas tsuaj vim cov khib nyiab hauv huab cua.

·Txhim kho Efficiency: Minimizes teem sij hawm piv rau ib kab kab uas yuav tsum tau hloov phau ntawv.

· Txoj Kev Rollers: Nruab nrog 20 txoj kev yob, suav nrog 2 lub kaum sab xis rau kev txhim kho me me yoj tsim raws li qhia hauv daim duab nrog.

·Cov Rollers ntev: Rollers yog chrome-plated thiab tshav kub-kho rau corrosion thiab xeb kuj, pab rau lub neej ntev kev pab cuam.

· Main Tsav: Tus qauv specification yog 380V, 50Hz, 3-theem, nrog rau kev xaiv rau customization muaj.

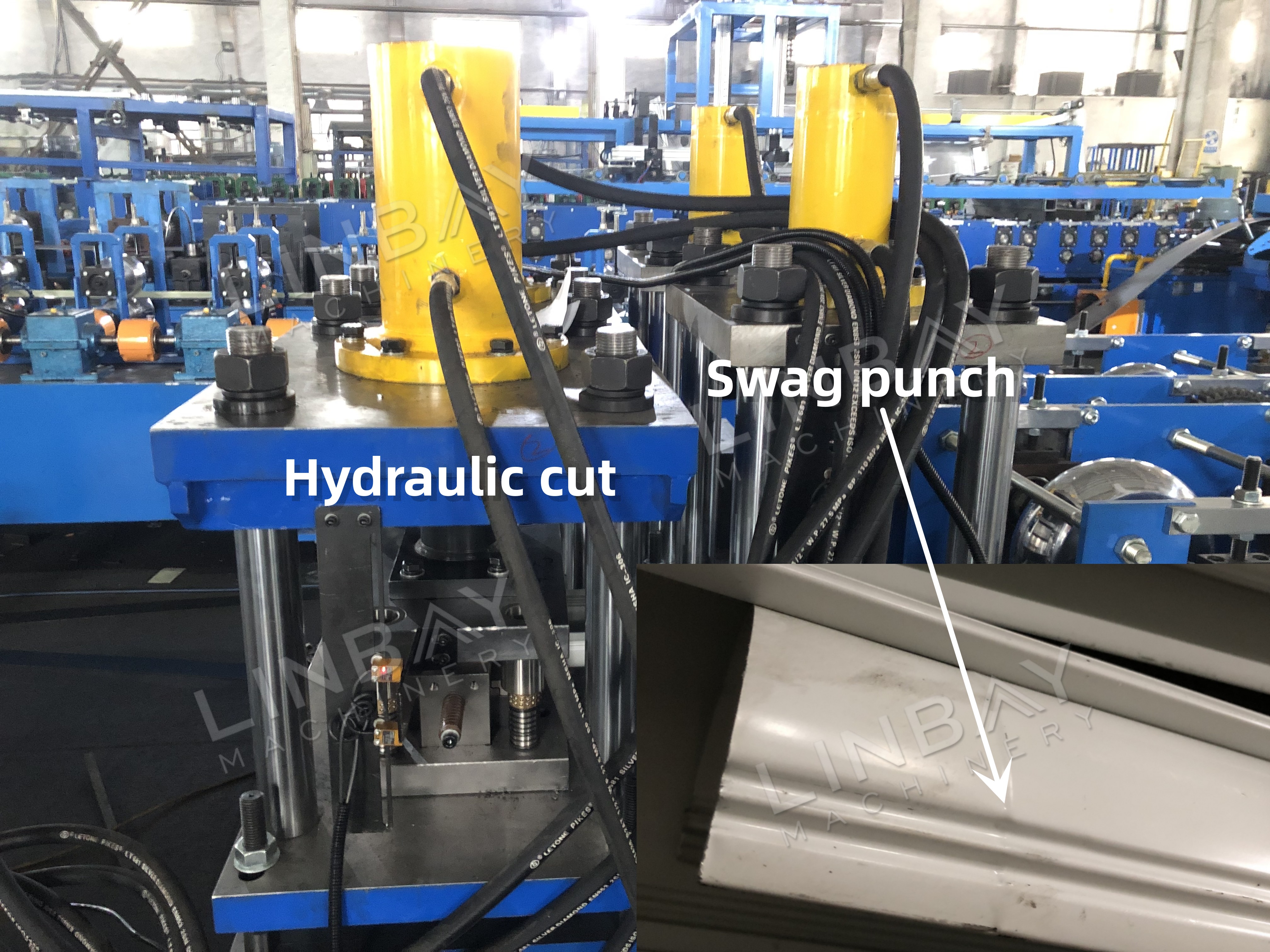

Swag Punching

· Gutter Configuration: Qhov kawg ntawm cov hlau gutter yog tapered kom txo nws txoj kab uas hla, ua kom nws swb mus rau lwm qhov gutter seem kom ruaj ntseg haum.

· Tshuab muaj peev xwm: Siv hydraulic xuas nrig ntaus tuag los ua qhov kawg kev sib txuas, kom ntseeg tau tias kev sib koom ua ke du thiab ruaj ntseg ntawm ob ntu gutter.

Hydraulic Txiav

· Custom Blades: Engineered kom haum lub gutter profile, kom huv si txiav tsis deformation los yog burrs.

· Qhov tseeb txiav ntev: Muaj kev kam rau siab ± 1mm. Qhov no precision yog tiav los ntawm ib tug encoder uas ntsuas lub steel kauj lub zog, converting cov ntaub ntawv no mus rau hauv hluav taws xob signals xa mus rau lub txee PLC. Cov neeg ua haujlwm tuaj yeem kho qhov ntev, ntau lawm, thiab nrawm ntawm PLC interface.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj