PROFILE

Awning round tubes yog cov khoom tseem ceeb rau awnings, feem ntau tsim los ntawm txhuas los yog galvanized steel. Standard diameters muaj xws li 60/63/70/78/80/85mm, thiab lawv feem ntau muaj nyob rau hauv ntev ntawm 4, 5, 6, los yog 7 meters.

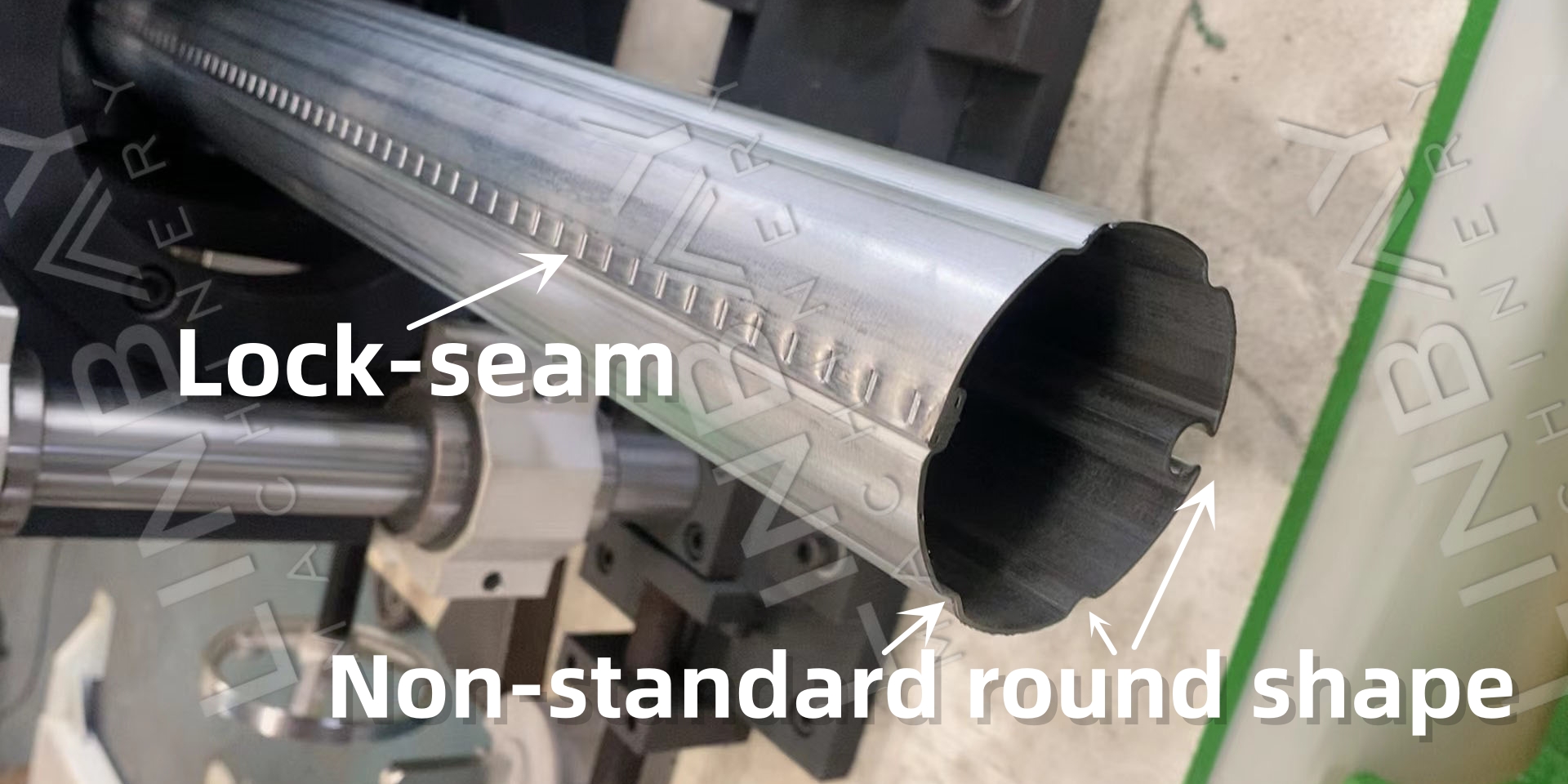

Cov txheej txheem ntau lawm: Hlau coils raug mob nyob ib ncig ntawm lub cylindrical pwm thiab ces compressed los ua ib puag ncig raj. Txoj hauv kev no ua rau muaj kev sib faib tsis sib luag, kev ua haujlwm tsawg, thiab kev txwv ntawm ob lub raj ntev thiab txoj kab uas hla tsawg kawg nkaus. Tsis tas li ntawd, nws yog ib qho nyuaj los tsim cov hlab ntsha uas tsis yog-tus qauv rounded ntug tsim, raws li qhia hauv daim duab hauv qab no.

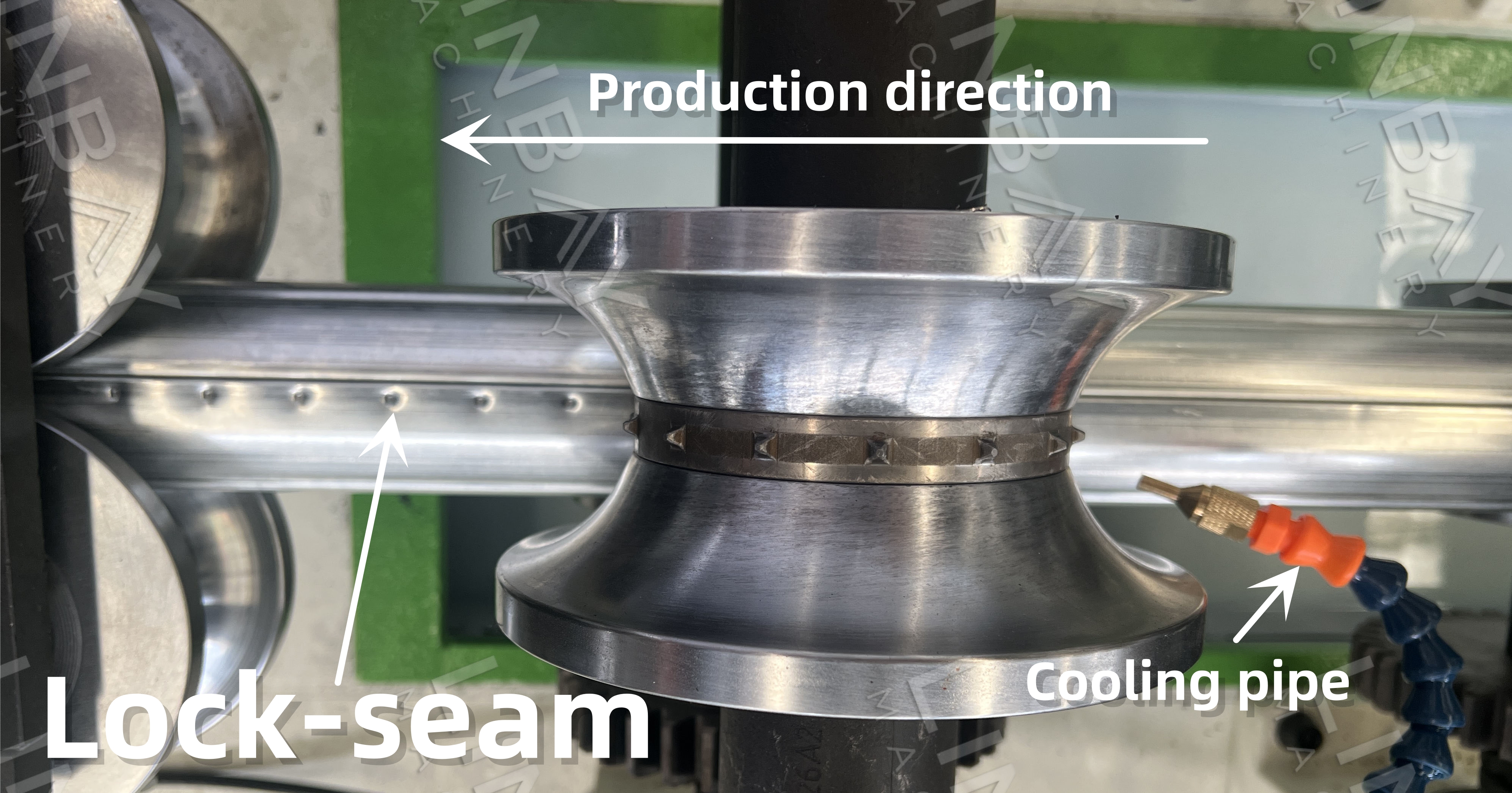

Txoj Kev Tshiab: Roll Forming Machine.Cov txheej txheem yob txoj kev maj mam ua cov khoom siv nrog txhua tus menyuam, incrementally bending nws kom txog thaum nws dhau los ua ib puag ncig, xauv-seamed raj. Qhov kev faib tawm tsis sib xws no minimizes springback. Hlau coils tuaj yeem noj tsis tu ncua yam tsis xav tau phau ntawv txiav ua ntej, thiab lub raj ntev tuaj yeem raug txiav nrog qhov tseeb ntawm ± 1mm. Txoj kev no yog qhov zoo tshaj plaws rau kev tsim cov raj me me thiab kev cai ntug tsim. Nws yog ib qho kev daws teeb meem zoo rau cov neeg siv khoom.

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

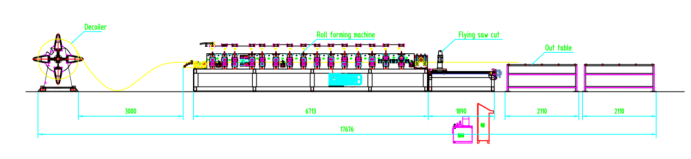

Flow chart: Decoiler--Guiding--Roll qub--Flying saw cut--Out table

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

1.Line ceev: 0-10m / min, adjustable

2.Suitable khoom: Galvanized steel, aluminium

3.Material thickness: 0.8-1mm

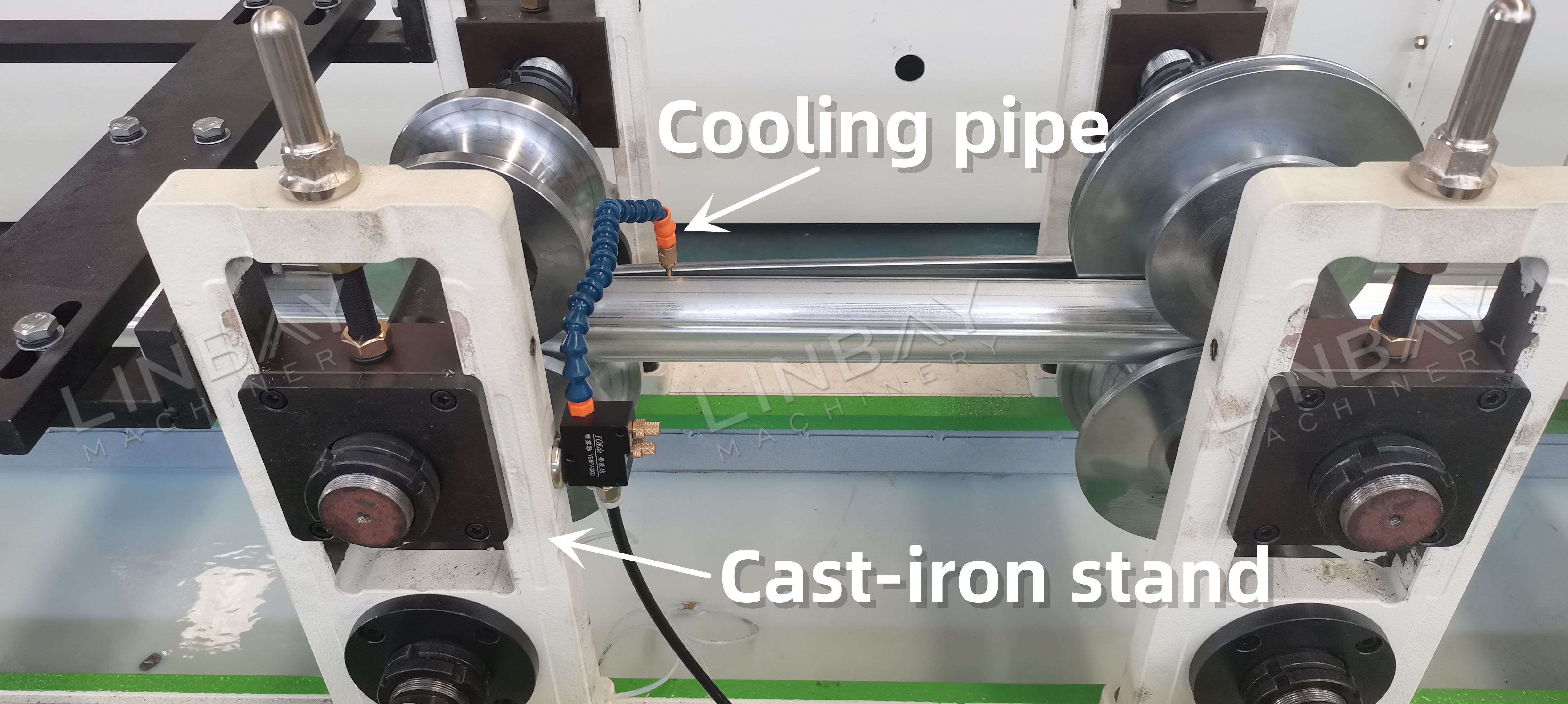

4.Roll forming tshuab: Cast-hlau qauv

5.Driving system: Gearbox tsav system nrog universal sib koom cardan ncej.

6.Cutting system: Flying saw txiav, yob qub tsis nres thaum txiav.

7.PLC txee: Siemens system.

TSEEM CEEB-MACHINERY

1.Manual Decoiler * 1

2. Roll forming tshuab * 1

3.Flying pom tej tshuab * 1 (xws li pom hniav * 1)

4.Out table*2

5.PLC tswj txee * 1

6.Hydraulic chaw nres tsheb * 1

7.Cov khoom seem lub thawv (Dawb) * 1

TSEEM CEEB-DESCRIPTION

Phau ntawv decoiler

· Sturdy Frame:Lub thav duab yog tsim kom muaj zog thiab ruaj khov, tshwj xeeb yog tsim los txhawb cov hlau coils ruaj ntseg.

· Mandrel Expansion:Lub mandrel lossis arbor tuaj yeem hloov kho manually kom nthuav dav thiab haum rau steel coils nrog ib txoj kab uas hla ntawm 490-510mm. Qhov no ua kom lub coil tuav ruaj khov kom du decoiling.

· Coil Retainer:Qhov kev tivthaiv no yog tsim los tiv thaiv cov hlau kauj los ntawm kev swb ntawm lub mandrel. Nws yooj yim rau txuas thiab tshem tawm.

· Muaj Kev Xaiv:Rau kev txhim kho lub zog thiab automation, hluav taws xob lossis hydraulic versions ntawm cov tub ntxhais nthuav dav yog muaj. Txawm li cas los xij, phau ntawv version yog qhov nyiam rau cov kav hlau txais xov puag ncig vim yog qhov nyias nyias thiab nqaim steel coils koom nrog.

Kev taw qhia

· Lub luag haujlwm tseem ceeb: Ua kom muaj kev sib raug zoo ntawm cov hlau kauj nrog lub tshuab qhov nruab nrab, tiv thaiv cov teeb meem xws li kev sib tw, khoov, thiab burr tsim. Kev sib raug zoo yog qhov tseem ceeb rau kev ua kom cov seams ntawm lub awning round raj yog nruj thiab ruaj ntseg.

· Ntau Txoj Kev Qhia: Nyob tsis yog ntawm qhov chaw pub mis xwb tab sis kuj thoob plaws hauv lub tshuab tsim kom ntseeg tau tias lub raj tseem ncaj thaum lub sijhawm tsim khoom.

· Routine Calibration: Tsis tu ncua calibration ntawm cov kev taw qhia systems yog tsim nyog, tshwj xeeb tshaj yog tom qab kev thauj mus los los yog ncua sij hawm ntawm kev siv.

· Cov ntaub ntawv ua ntej xa khoom xa tuaj: Pab pawg Linbay ua tib zoo ntsuas thiab sau cov lus qhia dav ua ntej ua zaub mov xa tuaj, muab cov ntsiab lus no hauv phau ntawv siv los pab kom muaj kev ntsuas raug raws li tus neeg siv khoom tau txais.

Roll qub

· Kev tsim kho muaj zog: Features lub cam khwb cia hlau sawv ntsug rau kev txhim kho durability.

· Muaj zog tsav System: Nruab nrog lub gearbox thiab universal sib koom ua ke uas xa cov kev tsav tsheb muaj zog rau cov menyuam, kom ntseeg tau tias muaj kev sib raug zoo ntawm cov hlau coils.

· Kev tsim kho yooj yim: Ib qho yob txoj kev tshuab hauv paus haum rau cov kab sib txawv, txhua qhov tsim kom haum rau cov raj raj diameters. Tsuas yog hloov cov cassettes los tsim cov raj ntawm qhov sib txawv.

· Nqi Efficiency: Muab kev daws teeb meem kev lag luam ntau dua los ntawm kev tshem tawm qhov xav tau ntawm cov kab ntau lawm rau cov kab sib txawv.

· Kev ruaj ntseg Seam: Tuaj yeem lav cov leeg xauv kom nruj uas tseem nyob tsis tau, tiv thaiv qee lub peev xwm ntawm cov leeg ua tsis tiav.

· Sustainable Cooling System: Siv cov txheej txheem rov ua kom txias txias kom cov menyuam kub qis, txhim kho kev ua haujlwm zoo thiab ua kom lub neej ntev.

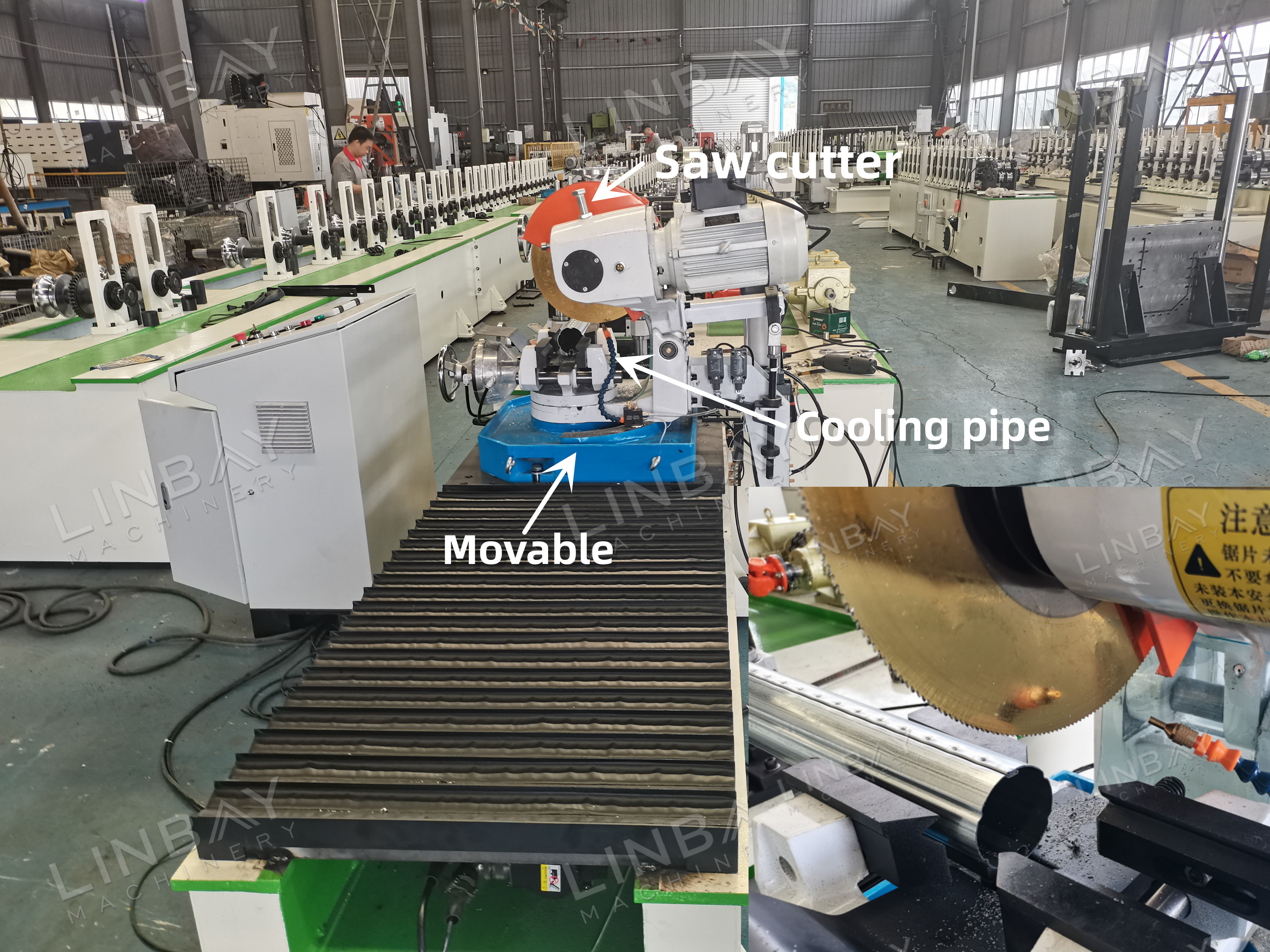

Flying Saw Hlais

· Ntau txoj kab uas hla: Tsim los ua kom haum rau ntau qhov ntau thiab tsawg, pab txo cov hniav hloov cov nqi.

· Precision Txiav: Ua kom huv, tsis muaj deformation txiav nrog cov npoo du, tsis muaj burr.

· Khoom siv tau zoo: Tshem tawm cov khib nyiab nrog txhua qhov kev txiav, ua kom zoo dua steel coil siv thiab txo cov nqi.

· Txhim khu kev ceev ceev: Lub tshuab cutter taug kev raws txoj kev ntawm tib lub nrawm raws li cov txheej txheem tsim, ua kom tsis muaj kev cuam tshuam.

· Siab raug: Kev koom ua ke nrog lub servo lub cev muaj zog thiab lub zog tswj, tswj kev txiav txim siab nyob rau hauv ± 1mm kam rau ua.

· Ua kom txias txias: Recirculates coolant kom cov saw hniav txias, kom ntseeg tau tias kev txiav zoo zoo thaum siv tas mus li thiab ua rau lub neej ntev.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj