SQUARE TUBE ROLL FORMING MACHINE

Cov kab ntau lawm no yog tsim los tsim cov raj square nrog lub thickness ntawm 2 hli, thiab qhov ntev li ntawm 50-100mm nyob rau hauv dav thiab 100-200mm nyob rau hauv qhov siab.

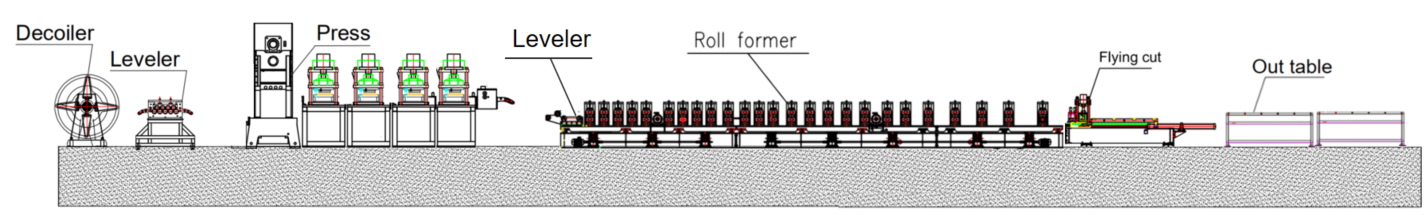

Cov kab ntau lawm suav nrog ntau cov txheej txheem tseem ceeb: decoiling, pre-punch leveling, punching, post-punch leveling, yob-forming, laser vuam, fume extraction, thiab txiav.

Featuring ib tug kev teeb tsa thiab siab heev automation, cov kab ntau lawm no muaj lwm txoj hauv kev rau cov pa vuam raj tshuab, tshwj xeeb tshaj yog rau cov khoom ntim qis.

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

Flow chart: Hydraulic decoiler nrog loading tsheb --- Qib--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding--Leveler--Yob qub--Laser weld--Flying saw txiav--Out rooj

TSEEM CEEB-MAIN TECHNICAL PARAMETERS

· Kho kab ceev: 5-6m / min nrog laser vuam

· Cov ntaub ntawv sib xws: Kub-kuav los tiag steel, txias-kuav los tiag steel, dub hlau

· Khoom thickness: 2mm

· Roll forming tshuab: Cam khwb cia hlau qauv nrog ib tug universal sib koom

· Tsav system: Gearbox-driven system featuring universal sib koom cardan ncej

· Txiav system: Flying saw txiav, nrog rau yob yav dhau los ua haujlwm txuas ntxiv thaum txiav

· PLC tswj: Siemens system

TSEEM CEEB-MACHINERY

1.Hydraulic decoiler * 1

2. Standalone Leveler * 1

3. Punch nias * 1

4.Hydraulic punch tshuab * 1

5.Servo feeder * 1

6.Integrated Leveler * 1

7. Roll forming tshuab * 1

8. Laser vuam tshuab * 1

9.Vuam Fume Purifier * 1

10.Flying pom tej tshuab * 1

11.Out table*2

12.PLC tswj txee * 2

13.Hydraulic chaw nres tsheb * 3

14.Spare lub thawv (Dawb) * 1

TSEEM CEEB-DESCRIPTION

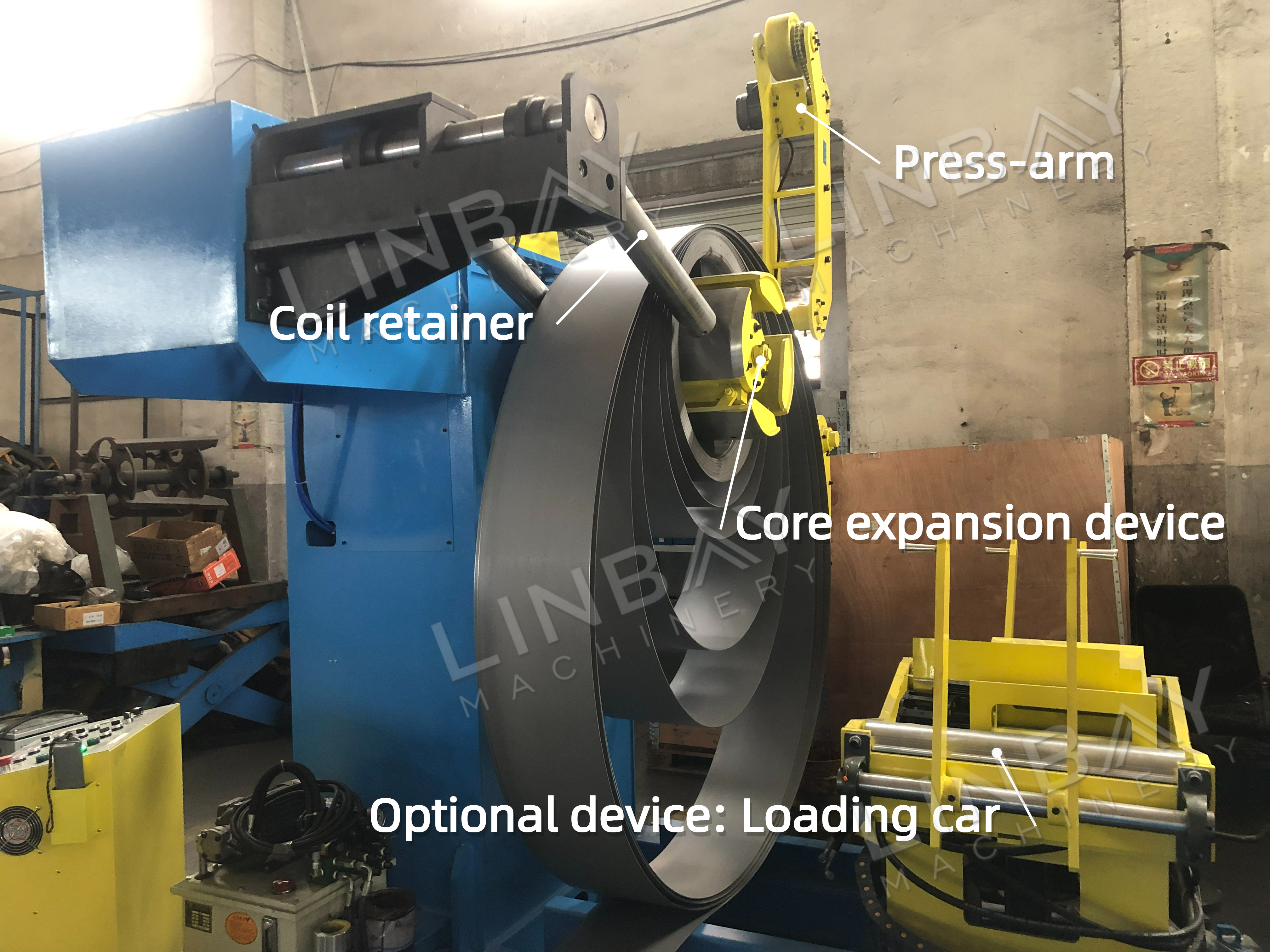

Hydraulic decoiler

•Muaj nuj nqi: Lub thav duab ruaj khov yog tsim los txhawb steel coil loading. Lub hydraulic decoiler txhim khu kev ua tau zoo thiab kev nyab xeeb hauv kev pub steel coils rau hauv cov kab ntau lawm.

•Core Expansion Device: Lub hydraulic mandrel los yog arbor adjusts kom haum steel coils nrog ib tug puab txoj kab uas hla ntawm 490-510mm, expanding thiab cog lus kom khov kho lub kauj thiab kom du decoiling.

•Nias-arm: Lub hydraulic xovxwm caj npab ruaj lub steel kauj, tiv thaiv abrupt uncoiling vim kev ntxhov siab sab hauv thiab tiv thaiv cov neeg ua haujlwm los ntawm kev raug mob.

•Coil Retainer: Tus tsim ua kom lub kauj nyob ruaj ntseg nyob rau hauv qhov chaw thaum tso cai rau yooj yim installation thiab tshem tawm.

•Tswj System: Lub kaw lus nta PLC thiab tswj vaj huam sib luag, uas suav nrog lub khawm nres thaum muaj xwm txheej ceev kom muaj kev nyab xeeb ntxiv.

Optional Device: Loading Car

•Kev Hloov Pauv Hloov Ua Haujlwm: Pab hloov cov hlau coils muaj kev nyab xeeb thiab ua tau zoo, txo cov nqi zog.

•Hydraulic Alignment: Lub platform tuaj yeem hloov kho hydraulically nce thiab nqis kom haum nrog lub mandrel. Tsis tas li ntawd, lub tsheb thauj khoom, uas haum nrog lub log, tuaj yeem txav tau hluav taws xob raws li txoj kev.

•Tsim kev nyab xeeb: Lub concave tsim nrees tuav cov hlau kauj, tiv thaiv kev zawv zawg.

Yeem tshuab: Shearer Butt Welder

· Txuas qhov kawg thiab tshiab steel coils, txo lub sijhawm pub mis thiab hloov cov kauj ruam rau cov kauj tshiab.

· Txo cov nqi zog thiab cov khoom pov tseg.

· Xyuas kom du, burr-dawb shearing kom raug sib dhos thiab vuam.

· Nta automated TIG welding kom zoo ib yam thiab muaj zog welds.

· suav nrog tsom iav kev nyab xeeb ntawm lub rooj vuam los tiv thaiv cov neeg ua haujlwm qhov muag.

· Ko taw pedal tswj ua kom kauj clamping yooj yim dua.

· Customizable rau txawv coil widths thiab tuaj yeem yooj yim sib xyaw rau hauv ntau cov kab ntau lawm hauv nws qhov dav.

Standalone Leveler

· Txo kev ntxhov siab thiab qhov tsis zoo ntawm cov hlau coils los ntawm cov yas deformation, tiv thaiv geometric yuam kev thaum lub sij hawm tsim.

· Leveling yog ib qho tseem ceeb rau coils thicker tshaj 1.5mm uas yuav tsum tau xuas nrig ntaus.

· Tsis zoo li cov txheej txheem sib xyaw ua ke nrog cov decoilers lossis yob txoj kev tshuab, cov neeg ua haujlwm ib leeg ua haujlwm ntawm qhov nrawm dua.

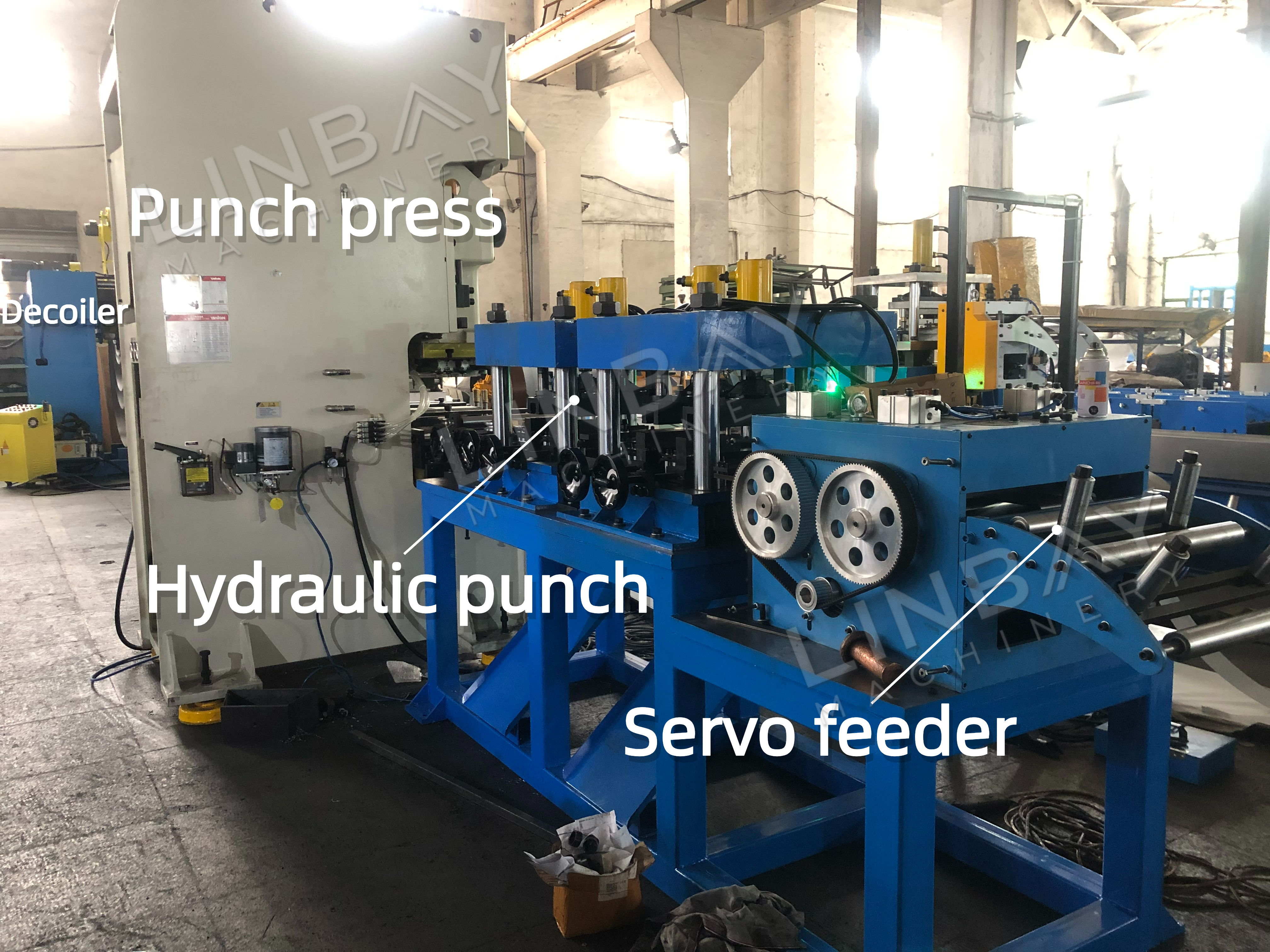

Punching Part

• Nyob rau hauv cov kab ntau lawm no, peb siv ib tug ua ke ntawm cov punch xovxwm thiab hydraulic punch rau lub qhov punching. Peb pab neeg ua haujlwm engineering tau tsim ib txoj hauv kev zoo rau kev tuav cov qauv qhov nyuaj, ntsuas qhov ua tau zoo thiab tus nqi los ntawm kev sib koom ua ke qhov zoo ntawm ob lub tshuab xuas nrig ntaus.

Punch Xovxwm

· Kev ua haujlwm ceev.

· Cov neeg raug siab hauv qhov sib nrug thaum xuas nrig ntaus.

· Zoo tagnrho rau cov qauv qhov ruaj khov.

Hydraulic Punch

• Muab kev hloov pauv ntau dua rau ntau lub qhov qauv. Lub tshuab xuas nrig ntaus hydraulic tuaj yeem hloov kho rau qhov sib txawv ntawm qhov sib txawv, kho qhov xuas nrig ntaus zaus raws li thiab xaiv xuas nrig ntaus sib txawv nrog txhua qhov mob stroke.

Servo Feeder

Lub feeder, uas tau tsav los ntawm lub servo lub cev muaj zog, precisely tswj cov pub ntawm steel coils rau hauv lub punch xovxwm los yog ib tug neeg hydraulic punch tshuab. Nrog lub sij hawm teb ceev thiab tsawg kawg pib-nres qeeb, servo motors xyuas kom meej qhov ntev pub thiab qhov sib npaug ntawm qhov sib txawv, zoo heev txo cov khib nyiab los ntawm kev xuas nrig ntaus. Cov txheej txheem no tseem muaj lub zog txuag, rub lub zog tsuas yog thaum lub sijhawm ua haujlwm, thiab txuag lub zog thaum lub sijhawm tsis ua haujlwm. Lub feeder yog programmable tag nrho, tso cai rau kev hloov pauv nrawm hauv kauj ruam nrug thiab xuas nrig ntaus nrawm, txiav rau lub sijhawm teeb tsa thaum hloov cov pwm pwm. Tsis tas li ntawd, sab hauv pneumatic clamping mechanism tiv thaiv cov hlau kauj ntawm qhov chaw los ntawm kev puas tsuaj.

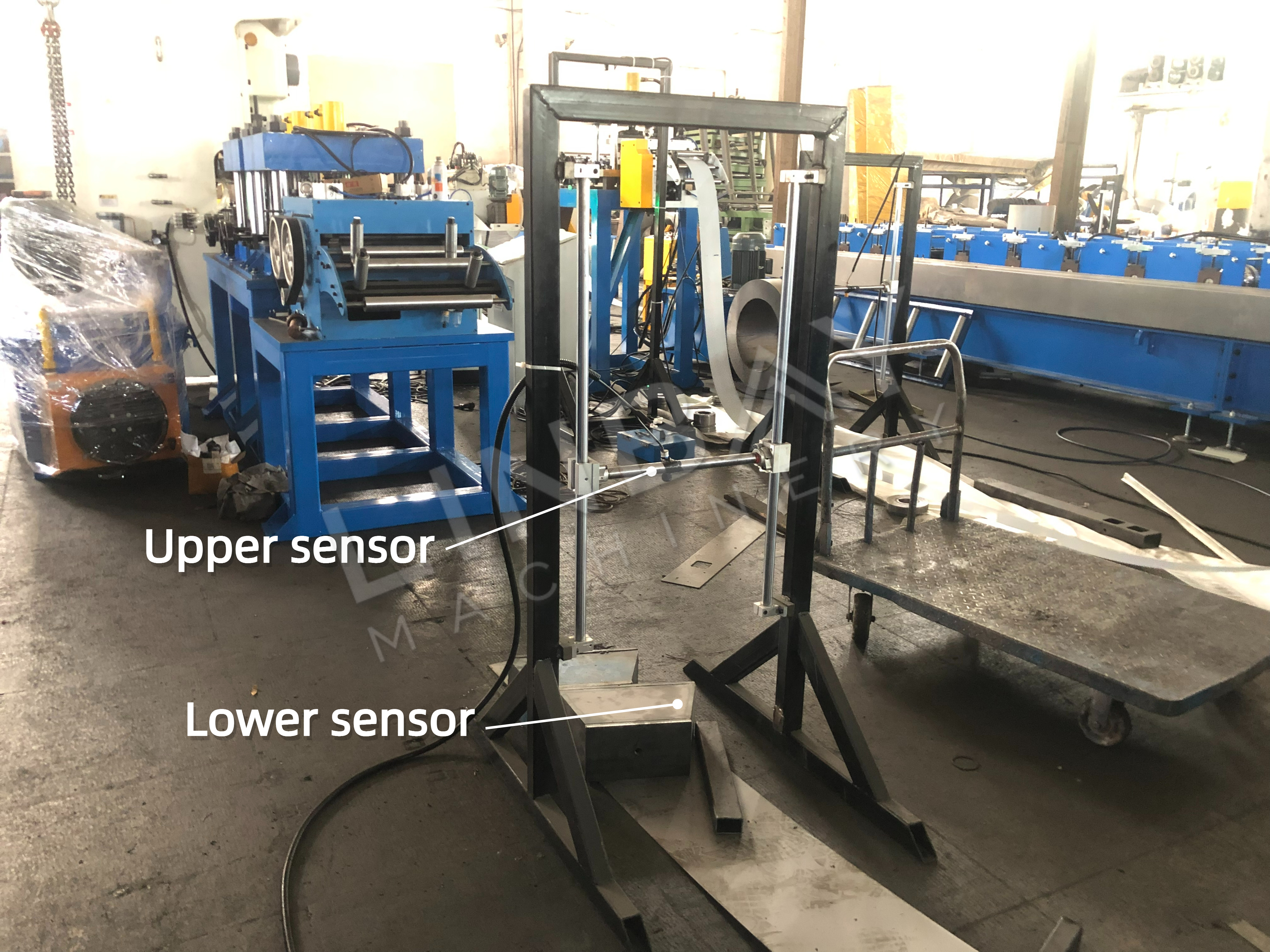

Txwv

Tswj cov pace ntawm ntau lawm los txhim kho kev ua tau zoo thiab tswj kev ua haujlwm zoo ntawm ob lub steel kauj thiab tshuab. Yog hais tias lub coil los rau hauv kev sib cuag nrog lub qis sensor, nws txhais tau hais tias lub uncoiling, leveling, thiab xuas nrig ntaus cov txheej txheem ua ntej ntawm lub limiter yog khiav ceev tshaj lub tom ntej no txoj kev, vuam, thiab txiav theem. Cov txheej txheem ua ntej no yuav tsum ncua kom sib npaug ntawm cov khoom ntws; txwv tsis pub, coil buildup yuav tshwm sim, obstructing nws du nkag mus rau hauv lub tshuab tsim thiab tej zaum yuav ua rau deformation. Piv txwv li, yog tias lub coil kov lub sensor sab saud, nws qhia tau tias cov theem tom qab tau txav nrawm dua li qhov ua ntej, yuav tsum tau nres hauv cov txheej txheem tom qab lub limiter. Kev ua tsis tiav tuaj yeem ua rau lub kauj raug rub mus rau hauv lub tshuab yob txoj kev nrawm heev, uas yuav ua rau muaj kev puas tsuaj rau lub tshuab xuas nrig ntaus thiab tsim cov chais. Txhua qhov kev ncua yuav ua rau muaj kev ceeb toom ntawm qhov sib thooj PLC txee tso saib, tso cai rau cov neeg ua haujlwm rov qab ua haujlwm los ntawm kev lees paub qhov tam sim ntawd.

Kev taw qhia

Lub hom phiaj tseem ceeb: Ua kom cov hlau coil ua kom zoo nrog lub tshuab qhov nruab nrab, tsis txhob muaj teeb meem xws li kev sib tw, khoov, burrs, thiab qhov tsis raug ntawm qhov khoom tiav. Kev taw qhia rollers tau muab tso rau hauv qhov chaw nkag thiab hauv lub tshuab tsim. Nws yog ib qho tseem ceeb rau calibrate cov kev taw qhia cov cuab yeej tsis tu ncua, tshwj xeeb tshaj yog tom qab thauj los yog siv lub tshuab yob txoj kev siv ntev. Ua ntej xa tawm, Linbay pab pawg ntsuas qhov dav dav thiab suav nrog cov ntaub ntawv no hauv cov neeg siv phau ntawv, tso cai rau cov neeg siv khoom ntsuas lub tshuab thaum xa khoom.

Secondary Leveler (Teem rau tib lub hauv paus nrog yob txoj kev tshuab)

Lub coil smoother ua kom zoo dua seam alignment post-forming, uas pab tau zoo heev hauv cov txheej txheem vuam. Secondary leveling pab ntxiv txhim kho qib zoo thiab txo kev ntxhov siab ntawm cov ntsiab lus punched. Raws li kev ntsuas ntxiv, muab qhov ntsuas qib no rau ntawm lub tshuab tsim lub hauv paus muab cov txiaj ntsig zoo thiab tsim nyog.

Roll Forming Tshuab

· Ntau yam ntau lawm: Cov kab no muaj peev xwm tsim cov raj square nrog qhov ntev ntawm 50-100mm hauv qhov dav thiab 100-200mm hauv qhov siab. (Linbay tseem tuaj yeem muab kev hloov kho rau lwm qhov loj me.)

· Automated Size Hloov: Los ntawm kev teeb tsa thiab lees paub qhov xav tau loj ntawm lub vijtsam PLC, cov chaw tsim khoom cia li hloov mus rau tom qab raws li cov lus qhia rau cov haujlwm meej, kho qhov tsim kom haum. Qhov no automation txhim kho qhov tseeb thiab yooj yim, txo qhov xav tau ntawm phau ntawv hloov kho thiab cov nqi cuam tshuam.

· Lateral Movement Detection: Tus encoder precisely taug qab lub lateral txav ntawm cov chaw tsim thiab instantly relays cov ntaub ntawv no mus rau lub PLC, tswj kev txav tsis raug nyob rau hauv ib tug 1 hli kam rau ua.

· Kev nyab xeeb txwv Sensors: Ob qhov kev txwv tsis pub muaj kev nyab xeeb yog nyob rau sab nraud ntawm cov lus qhia. Lub sensor sab hauv tiv thaiv cov chaw tsim khoom los ntawm kev txav ze ze ua ke, zam kev sib tsoo, thaum lub sensor sab nraud xyuas kom lawv tsis txhob txav mus deb dhau.

· Sturdy Cast-iron Frame: Featuring ib tug ywj siab upright thav duab ua los ntawm cam khwb cia hlau, cov khoom no yog zoo tagnrho rau high-muaj peev xwm ntau lawm yuav tsum tau.

· Powerful Drive System: Lub gearbox thiab universal sib koom ua ke xa lub zog muaj zog, ua kom muaj kev ua haujlwm zoo thaum nce coils thicker dua 2mm lossis ntawm kev sib sau nrawm tshaj 20m / min.

· Cov Rollers ntev: Chrome-plated thiab kub-kho, cov chais no tiv thaiv xeb thiab xeb, ua kom lub neej ntev dua.

· Main Tsav: Tus qauv teeb tsa yog 380V, 50Hz, 3-theem, nrog rau kev xaiv rau kev hloov kho muaj.

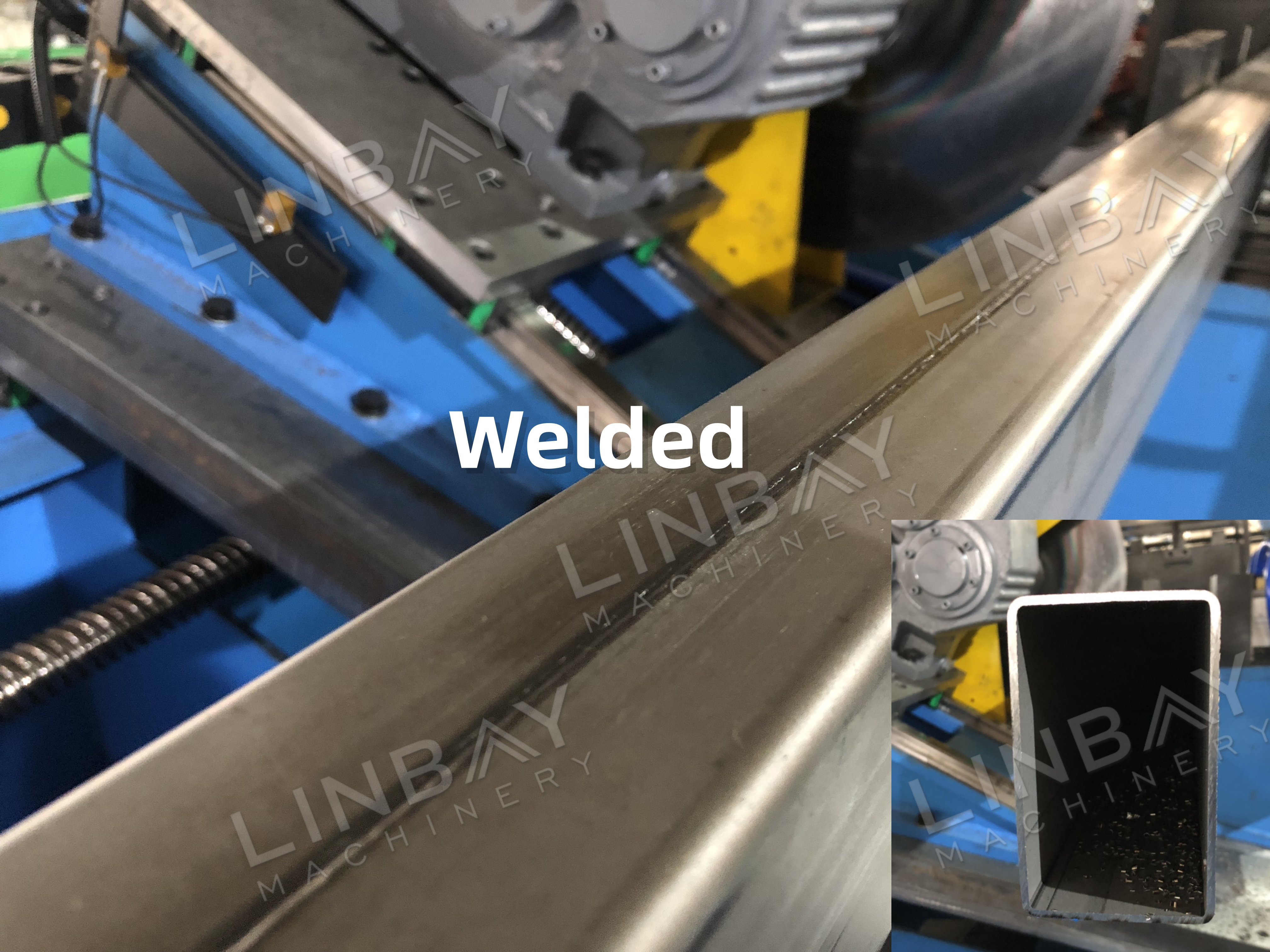

Laser Weld

· Enhanced Quality thiab Precision: Muab qhov tseeb tshaj plaws thiab kev sib txuas ruaj khov.

· Zoo thiab Polished Joint: Ua kom huv si, du tiav ntawm qhov sib koom ua ke.

Vuam Fume Purifier

• Kev tswj cov ntxhiab tsw thiab fume: ntes tau zoo thiab tshem tawm cov ntxhiab tsw thiab fumes uas tsim thaum lub sij hawm vuam, ua kom muaj kev nyab xeeb ntawm lub Hoobkas thiab tiv thaiv cov neeg ua haujlwm noj qab haus huv.

Flying Saw Hlais

· Flying Hlais: Lub tshuab txiav synchronizes nrog yob txoj kev tshuab ceev thaum lub sijhawm ua haujlwm, txhawb kev ua haujlwm ntau lawm thiab tso tawm.

· Precision Txiav: Nrog lub servo lub cev muaj zog thiab lub zog tswj, lub tshuab txiav tswj qhov tseeb ntawm ± 1mm.

· Txoj Kev Sawing: Muab cov txiav txiav yam tsis muaj deforming cov npoo ntawm cov square-kaw profiles.

· Khoom siv tau zoo: Txhua qhov txiav tsim cov khoom pov tseg tsawg, txo cov nqi khoom.

·Kev ua haujlwm yooj yim: Tsis zoo li lwm txoj kev txiav uas xav tau cov hniav tshwj xeeb rau ntau qhov sib txawv, txiav txiav yog hloov tau, muab cov nqi txuag ntawm cov hniav.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj