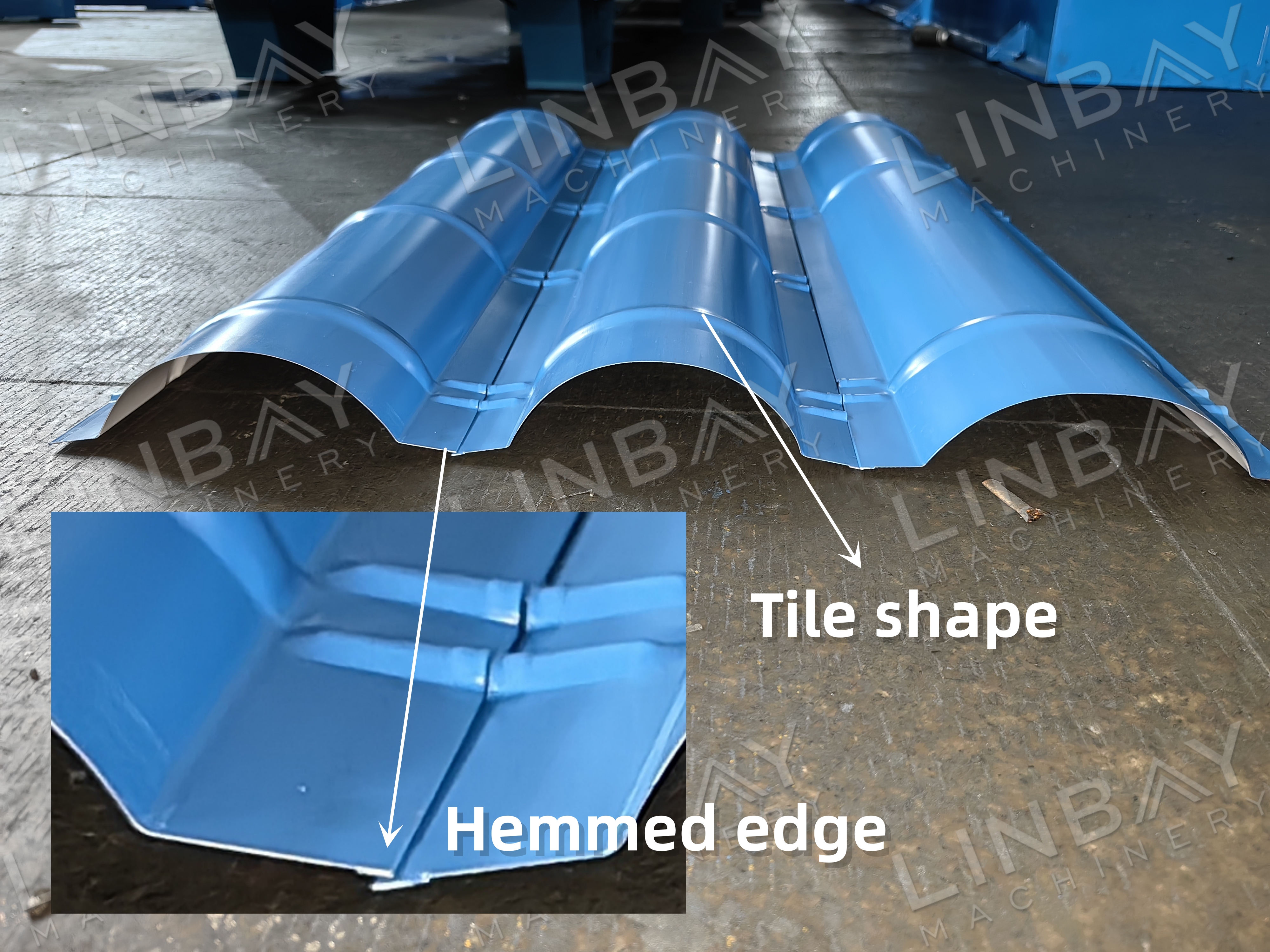

Profile

Lub ridge cap ruaj ntseg seam qhov twg ob lub ru tsev slopes sib ntsib, zoo tiv thaiv cheeb tsam los nag thiab plua plav. Cov kaus mom no muaj nyob rau hauv ntau yam duab los ua kom sib txawv ntawm cov hlau vov tsev thiab yog tsim los ntawm 0.3-0.6mm xim-coated steel, PPGI, thiab galvanized steel.

Cov ntaub ntawv tiag-Main Techinical Parameters

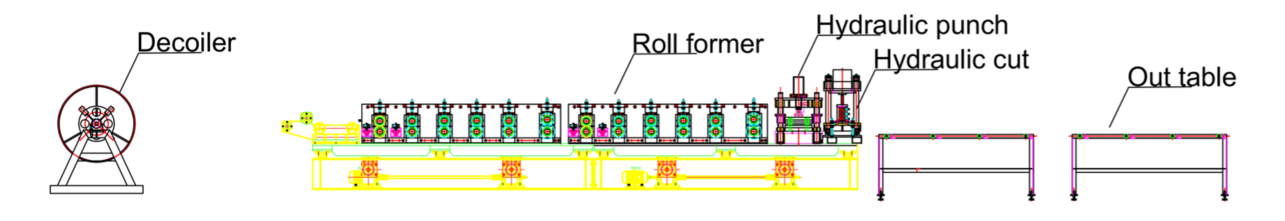

Flow chart: Decoiler--Guiding--Roll forming machine--Hydraulic punch--Hydraulic cut--Out rooj

Cov ntaub ntawv tiag-Main Technical Parameters

· Kho kab ceev: 0-10m / min

· Cov ntaub ntawv sib xws: Xim-coated steel, galvanized steel, thiab PPGI

· Khoom thickness: 0.3-0.6mm

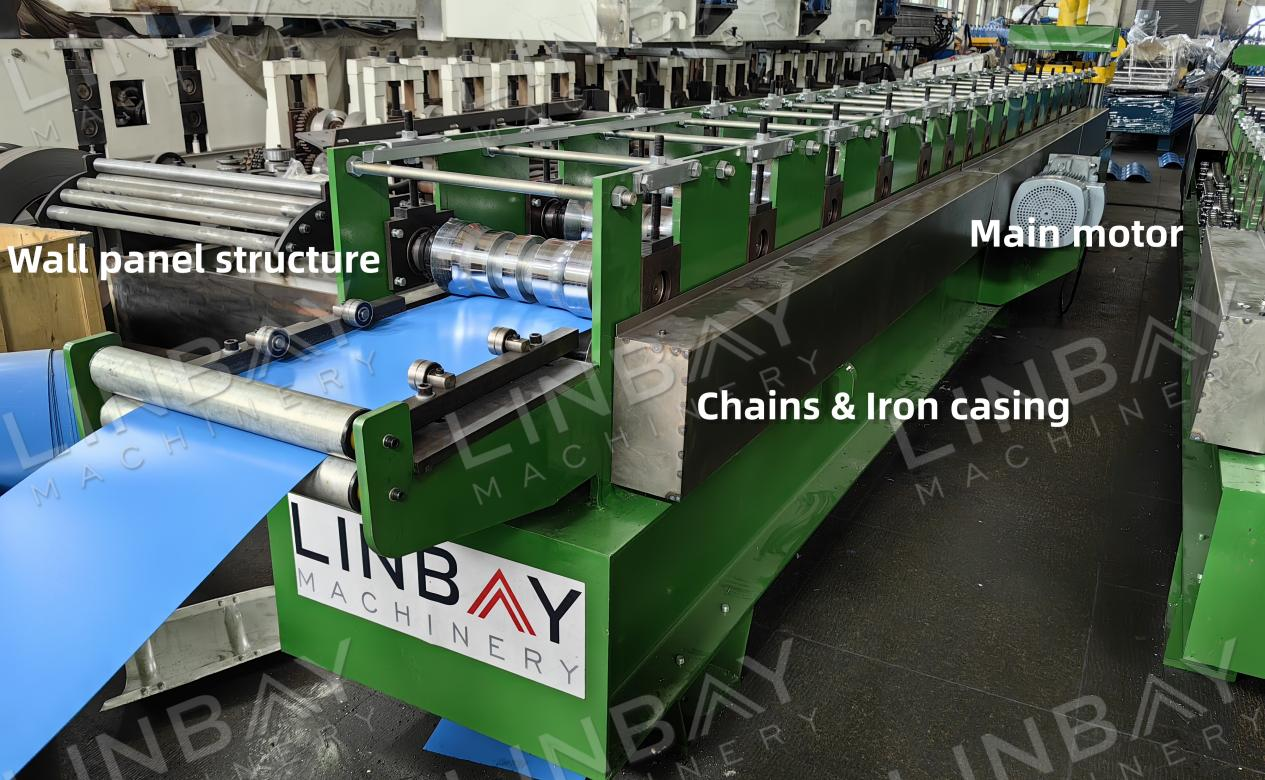

· Roll forming machine type: Phab ntsa vaj huam sib luag

· Tsav system: saw mechanism

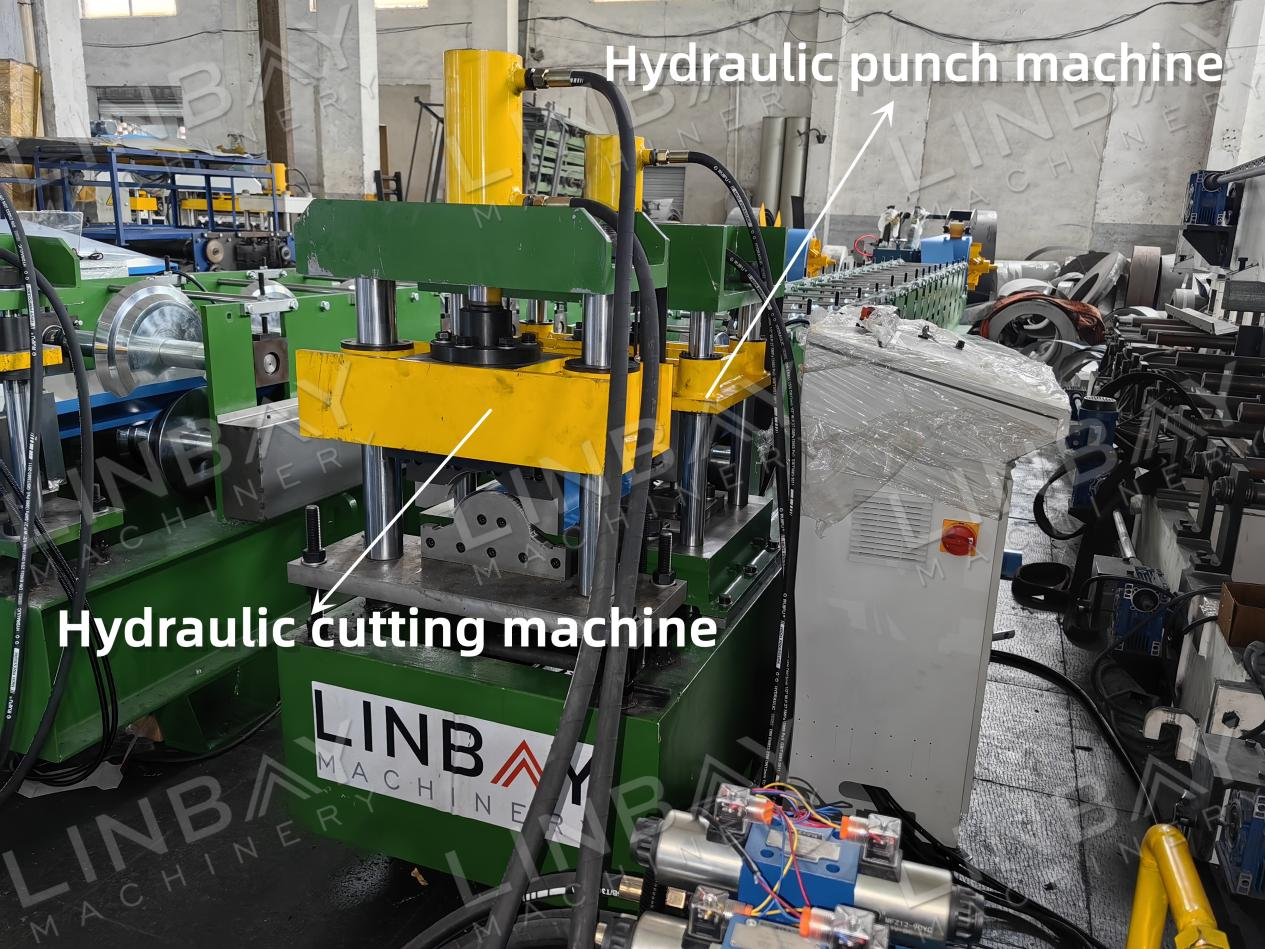

· Txiav system: Hydraulic txiav, nrog lub yob qub halting thaum lub sij hawm txiav

· PLC tswj: Siemens system

Cov ntaub ntawv tiag-Machinery

1.Manual decoiler * 1 (Peb kuj muab hluav taws xob thiab hydraulic decoiler, paub ntau ntxiv hauv DESCRIPTION hauv qab no)

2. Roll forming tshuab * 1

3.Hydraulic punch tshuab * 1

4.Hydraulic tej tshuab * 1

5.Out table*2

6.PLC tswj txee * 1

7.Hydraulic chaw nres tsheb * 1

8. Cov khoom seem lub thawv (Dawb) * 1

Cov ntaub ntawv tiag tiag-Kev piav qhia

Decoiler

Lub decoiler muaj nyob rau hauv phau ntawv, hluav taws xob, thiab hydraulic versions, xaiv raws li steel kauj lub thickness, dav, thiab qhov hnyav. Ib phau ntawv decoiler yog qhov tsim nyog los txhawb kev ruaj ntseg ntawm 0.6mm tuab kauj, kom ntseeg tau tias du thiab ruaj khov uncoiling.

Lub hauv paus ncej ntawm lub uncoiler, tseem hu ua cov tub ntxhais expansion ntaus ntawv, yog tsim los tuav lub steel kauj, muaj peev xwm nthuav los yog daim ntawv cog lus kom haum rau lub puab diameters li ntawm 460-520mm, kom ruaj ntseg thiab du uncoiling. Tsis tas li ntawd, ib qho kev tuav pov hwm sab nraud yog suav nrog los tiv thaiv lub kauj los ntawm kev plam tawm, txhim kho kev nyab xeeb ntawm cov neeg ua haujlwm.

Kev taw qhia

Kev taw qhia chais pab cov hlau coil smoothly nkag mus rau hauv lub yob txoj kev tshuab, kom ntseeg tau tias kev sib raug zoo nrog lub centerline ntawm lwm lub tshuab. Qhov kev sib raug zoo no yog qhov tseem ceeb rau kev tswj xyuas qhov ncaj ntawm lub taub hau thiab ua kom ntseeg tau qhov tseeb ntawm cov ntsiab lus siab.

Roll forming tshuab

Cov phab ntsa vaj huam sib luag ua ke nrog cov saw-tsav system ua tau zoo ua cov ntawv nyias nyias xws li ntawm 0.3-0.6mm hauv tuab, muab cov txiaj ntsig zoo. Cov saw hlau yog kaw nyob rau hauv ib tug hlau casing, muab kev tiv thaiv rau cov neeg ua hauj lwm thiab tiv thaiv chains los ntawm cov khib nyiab puas. Raws li cov hlau kauj dhau los ntawm kev sib sau cov chais, nws raug rau siab thiab tensile rog, ua rau cov duab xav tau.

Lub kaw lus suav nrog 16 qhov chaw tsim khoom, txhua qhov ua tau zoo raws li cov neeg siv khoom tshwj xeeb, suav nrog yoj qhov siab, lub vojvoog arc, thiab cov npoo ncaj ntawm ob sab ntawm lub taub hau. Cov chaw nres tsheb no yog tsim los tiv thaiv kev khawb ntawm lub coil nto los yog kev puas tsuaj rau cov xim txheej.

Lub hau npog no suav nrog cov npoo hemmed txhawm rau txhim kho kev nyab xeeb los ntawm kev txo qis thiab tiv thaiv cov neeg ua haujlwm los ntawm kev raug mob. Cov qauv tsim hemmed tseem zais cov ntug hlau, tiv thaiv ntug nkag thiab txo qhov kev pheej hmoo ntawm xeb tsim ntawm ntug ntug ntug.

Stamping

Thaum tsim, steel kauj yuav siv sij hawm nyob rau hauv ib tug semi-circular duab. Tom ntej no, lub tshuab xuas nrig ntaus hydraulic yog ua haujlwm los stamp tus qauv tsa rau ntawm pobzeb. Cov txheej txheem no tsis tsuas yog tsim cov pobzeb tab sis kuj txhim kho lub zog ntev ntawm lub hau ridge. Lub stamping zaus tuaj yeem hloov kho ntawm PLC npo, thiab cov pwm stamping tuaj yeem hloov kho kom haum rau koj cov kev qhia tshwj xeeb.

Encoder, PLC Tswj txee, & Hydraulic txiav

Lub encoder yog ntsuas qhov ua ntej steel kauj qhov ntev thiab hloov qhov ntsuas no mus rau hauv lub teeb liab hluav taws xob xa mus rau PLC tswj txee. Cov neeg ua haujlwm tuaj yeem tsim kho qhov nrawm, batch loj, thiab txiav ntev ncaj qha los ntawm PLC txee npo. Ua tsaug rau cov lus qhia meej los ntawm tus encoder, lub tshuab txiav hydraulic tuaj yeem tswj tau qhov kev txiav txim siab ntev li ntawm ± 1 hli. Tsis tas li ntawd, cov hniav txiav yog kev cai tsim raws li cov duab kos, kom huv si, deformation-dawb npoo thiab tshem tawm burrs.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj