Profile

DIN rail yog ib qho qauv hlau rail uas nquag siv hauv hluav taws xob engineering. Nws tus qauv tsim ua kom yooj yim rau kev teeb tsa thiab tshem tawm cov khoom, feem ntau muaj cov kab los yog qhov rau txuas siv cov ntsia hlau lossis snap-on mechanisms. Tus qauv qhov ntev ntawm DIN rails yog 35mm x 7.5mm thiab 35mm x 15mm, nrog tus qauv tuab ntawm 1mm.

Cov ntaub ntawv tiag-Main Technical Parameters

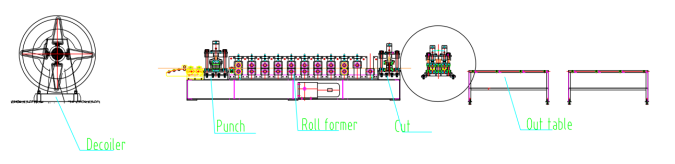

Flow daim ntawv: Decoiler--Guiding--Hydraulic punch--Roll forming tshuab--Hydraulic txiav tshuab

1.Line ceev: 6-8m / min, adjustable

2.Suitable khoom: Kub dov hlau, txias dov hlau

3.Material thickness: Cov txheej txheem thickness yog 1 hli, thiab cov kab ntau lawm tuaj yeem ua raws li qhov tuab ntawm 0.8-1.5 hli.

4.Roll forming tshuab: Phab ntsa vaj huam sib luag qauv

5.Driving system: saw tsav tsheb

6.Cutting system: nres txiav, yob qub nres thaum txiav.

7.PLC txee: Siemens system.

Tshuab

1.Decoiler * 1

2. Roll forming tshuab * 1

3.Out table*2

4.PLC tswj txee * 1

5.Hydraulic chaw nres tsheb * 1

6. Cov khoom seem lub thawv (Dawb) * 1

Thawv loj: 1x20GP

Cov ntaub ntawv tiag tiag-Kev piav qhia

Decoiler

Lub decoiler yog thawj feem ntawm cov kab ntau lawm. Muab cov tuab me me thiab qhov loj ntawm DIN ntsia, phau ntawv decoilers tsim nyog kom ua tau raws li qhov yuav tsum tau ua. Txawm li cas los xij, rau kev ua haujlwm siab dua, peb kuj muab cov kev daws teeb meem nrog hluav taws xob thiab hydraulic decoilers.

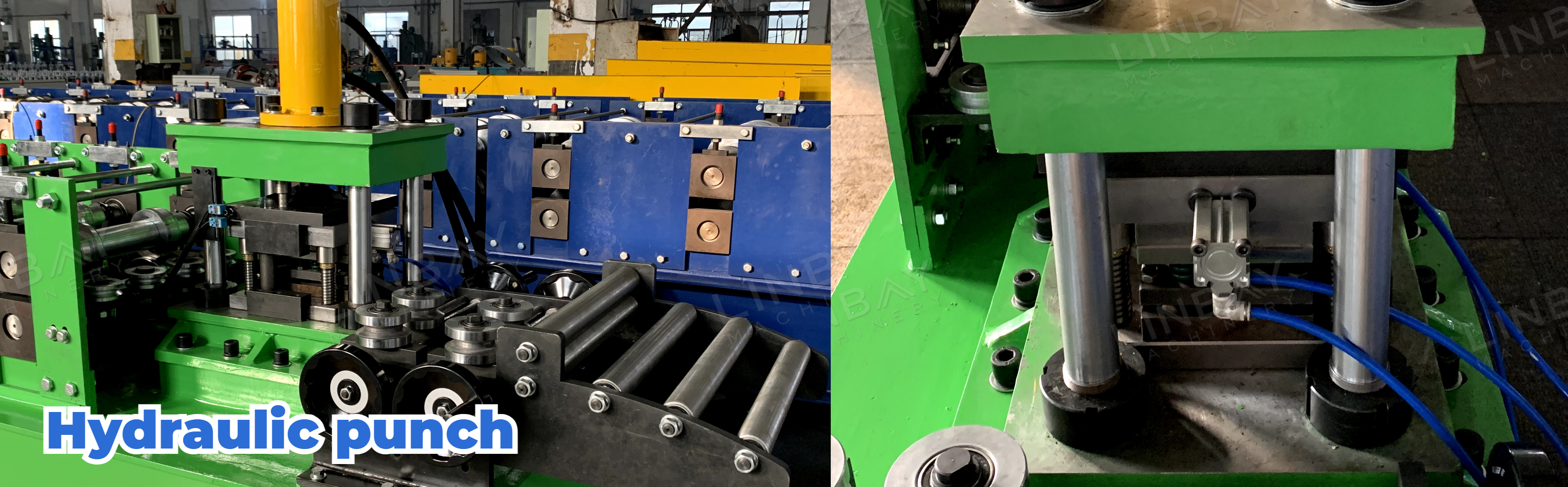

Hydraulic punch

Nyob rau hauv qhov teeb meem no, hydraulic punch yog kev koom ua ke nrog lub ntsiab sib sau tshuab, sib koom tib lub hauv paus. Thaum lub sij hawm xuas nrig ntaus, cov hlau kauj ib ntus nres nkag mus rau hauv lub tshuab tsim. Rau cov ntawv thov uas xav tau ntau dua nrawm, standalone hydraulic punch tshuab muaj.

Kev taw qhia

Cov kev taw qhia cov menyuam ua kom muaj kev sib haum xeeb ntawm cov hlau kauj thiab lub tshuab, tiv thaiv kev cuam tshuam thaum lub sijhawm ua haujlwm.

Roll forming tshuab

Qhov no yob txoj kev tshuab siv cov phab ntsa vaj huam sib luag thiab cov saw tsav tsheb. Nws txoj kev tsim dual-kab ua rau kev tsim khoom ntawm ob qhov ntau thiab tsawg ntawm DIN rail. Txawm li cas los xij, nws yuav tsum raug sau tseg tias ob kab tsis tuaj yeem ua haujlwm ib txhij. Rau kev xav tau ntau dua, peb pom zoo kom teeb tsa cov kab ntau lawm rau txhua qhov loj.

Nws yuav tsum tau hais tias qhov txiav ntev precision ntawm yob txoj kev tshuab nrog ob-kab qauv yog nyob rau hauv ± 0.5 hli. Yog tias koj qhov kev xav tau precision tsawg dua ± 0.5mm, nws tsis pom zoo kom siv cov qauv ob kab. Hloov chaw, kev daws teeb meem ntawm kev muaj cov kab ntau lawm ywj siab rau txhua qhov loj yog tsim nyog.

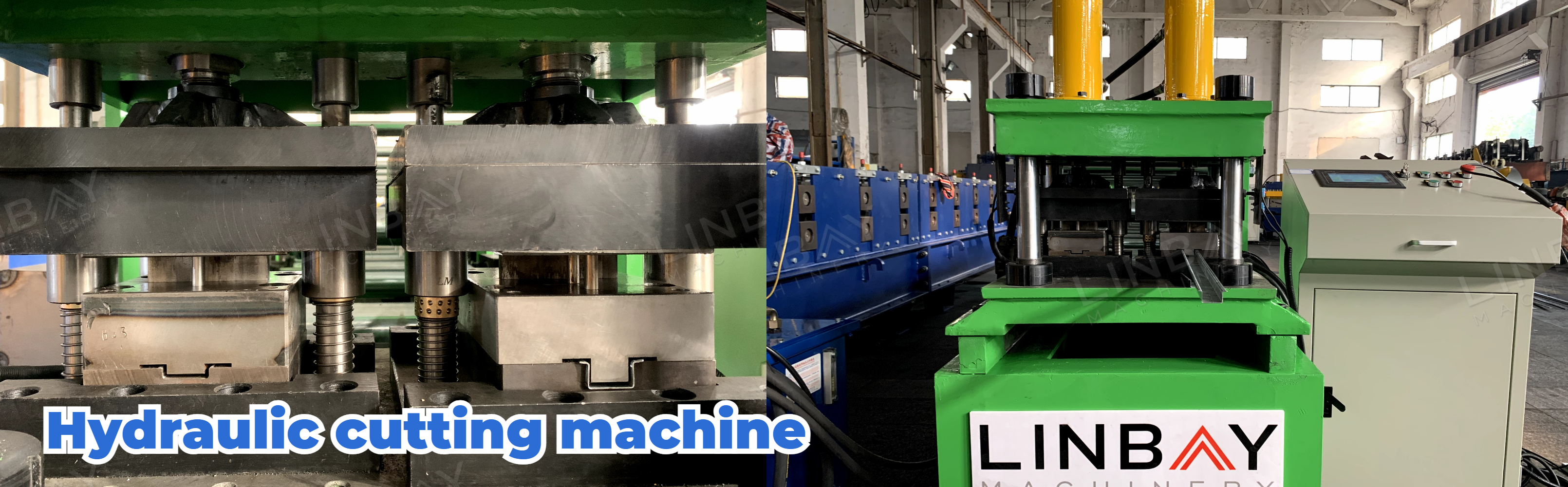

Hydraulic txiav tshuab

Lub hauv paus ntawm lub tshuab txiav tseem nyob ruaj khov thaum lub sijhawm ua haujlwm, ua rau cov hlau coil nres nws txoj kev nce qib thaum txiav.

Yuav kom ua tiav ntau lawm ceev, peb muab ib tug ya tej tshuab. Lo lus "flying" qhia tias lub tshuab txiav lub hauv paus tuaj yeem txav mus los. Qhov kev tsim no ua rau cov hlau coil nce mus tas li los ntawm kev siv lub tshuab thaum txiav, tshem tawm qhov xav tau kom tsis txhob siv lub tshuab ua haujlwm thiab yog li txhim kho tag nrho cov kab ntau lawm.

Cov hniav tuaj pwm ntawm qhov kawg ntawm txhua kab yog kho kom haum rau cov duab ntawm qhov loj ntawm DIN rail.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj