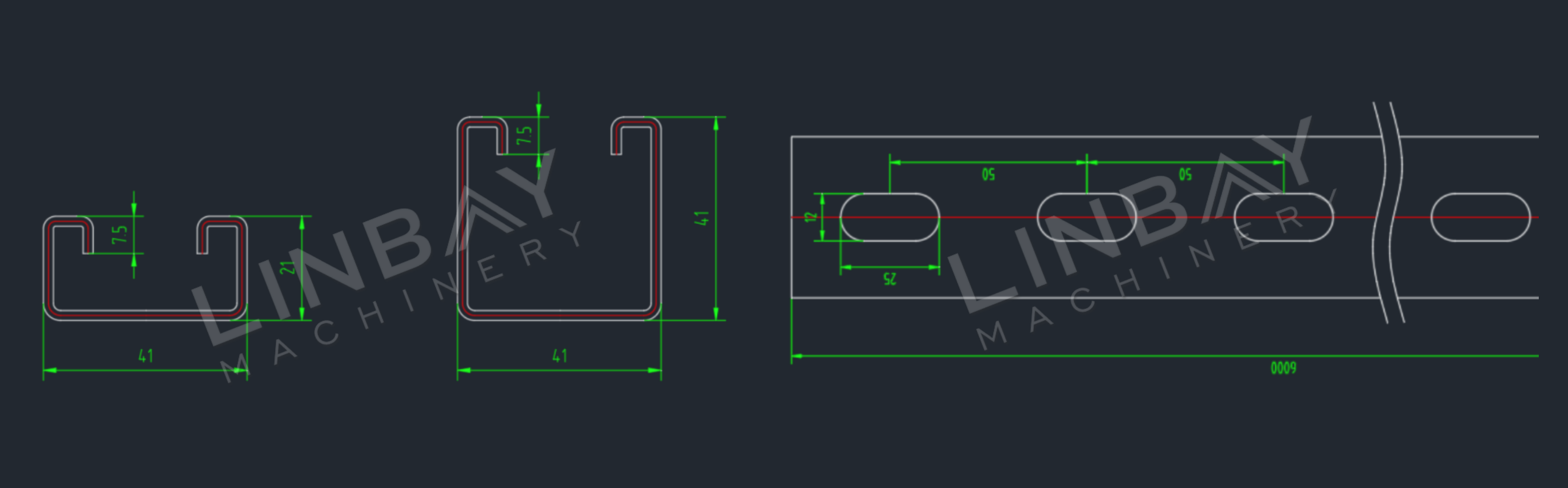

Profile

Strut channels feem ntau yog ua los ntawm galvanized steel nrog thicknesses ntawm 1.5-2.0mm los yog 2.0-2.5mm, los yog stainless hlau nrog thicknesses ntawm 1.5-2.0mm. Lawv tau tsim los nrog cov qhov tsis tu ncua los yog cov qhov nyob ntawm lawv qhov ntev, ua kom yooj yim txuas ntawm bolts, ceev, lossis lwm yam fasteners.

Cov kab ntau lawm nrog kev hloov pauv loj yog qhov zoo rau kev tsim ntau qhov ntau thiab tsawg, xws li qhov ntev xws li 41 * 41, 41 * 21, 41 * 52, 41 * 62, 41 * 72, thiab 41 * 82mm. Qhov siab dua qhov siab ntawm strut channel, ntau qhov chaw tsim khoom yuav tsum tau ua, uas nyob rau hauv lem nce tus nqi ntawm yob txoj kev tshuab.

Cov ntaub ntawv tiag-Main Technical Parameters

Flow daim ntawv qhia

Hydraulic decoiler nrog qib--Servo feeder--Punch xovxwm--Guiding--Roll forming tshuab--Yav hydraulic txiav--Tawm rooj

Main Techinical Parameters

1.Line ceev: 15m / min, adjustable

2.Dimension: 41 * 41mm thiab 41 * 21mm.

3.Material thickness: 1.5-2.5mm

4.Suitable khoom: galvanized steel

5.Roll forming tshuab: cam khwb cia hlau qauv thiab gearbox tsav system.

6.Cutting thiab dabtsi yog khoov system: Flying hydraulic txiav. Roll qub tsis nres thaum txiav.

7. Hloov loj: Tsis siv neeg.

8.PLC txee: Siemens system.

Cov ntaub ntawv tiag tiag-Kev piav qhia

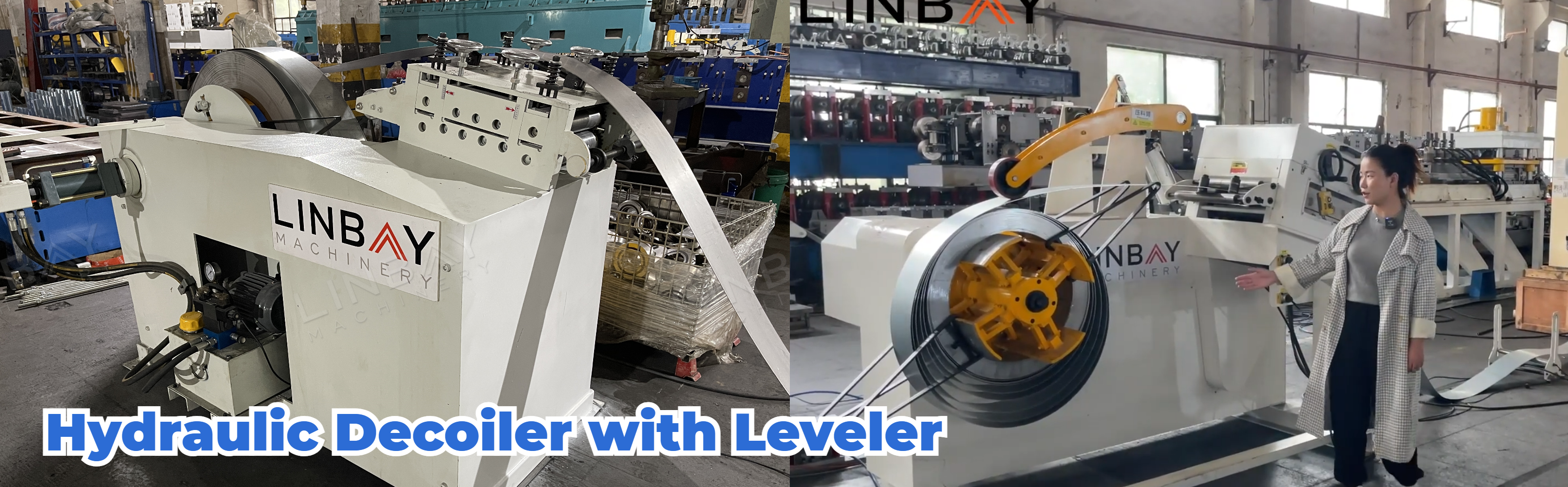

Hydraulic decoiler nrog leveler

Hom decoiler no, tseem hu ua "2-hauv-1 decoiler thiab leveler," nta cov qauv tsim uas tuaj yeem txuag tau li ntawm 3 meters ntawm qhov chaw tsim khoom, yog li txo cov nqi hauv av rau peb cov neeg siv khoom. Tsis tas li ntawd, qhov luv luv ntawm decoiler thiab leveler txo qhov teeb meem teeb meem, ua rau coil pub thiab ua haujlwm yooj yim dua.

Servo Feeder & Punch Xovxwm

Lub servo lub cev muaj zog ua haujlwm nrog zoo tsis muaj lub sijhawm pib-nres ncua sijhawm, ua kom muaj kev tswj xyuas meej ntawm cov coil pub ntev rau kev xuas nrig ntaus. Internally, pneumatic pub nyob rau hauv lub feeder zoo tiv thaiv lub coil nto los ntawm puas.

Feem ntau, qhov sib nrug ntawm lub strut channel yog 50 hli, nrog lub suab punching ntawm 300 hli. Piv rau hydraulic punch tshuab nrog sib npaug punching quab yuam, lub punch xovxwm ua tiav qhov nrawm nrawm ntawm kwv yees li 70 zaug hauv ib feeb.

Thaum cov nqi pib nqis peev rau cov punch presses yuav siab dua rau hydraulic punches, lawv muab cov txiaj ntsig zoo rau lub sijhawm ntev, tshwj xeeb tshaj yog rau cov khoom ntim ntau. Tsis tas li ntawd, kev saib xyuas tus nqi rau cov punch presses yuav qis dua vim lawv cov khoom siv tshuab yooj yim dua.

Peb tau xaiv Yangli hom punch xovxwm los ntawm Tuam Tshoj raws li peb qhov tseem ceeb thiab kev xaiv mus sij hawm ntev vim Yangli muaj ntau lub chaw haujlwm thoob ntiaj teb, muab kev txhawb nqa tom qab muag thiab kev pabcuam raws sijhawm rau peb cov neeg siv khoom.

Kev taw qhia

Kev taw qhia rollers xyuas kom meej tias lub kauj thiab lub tshuab ua raws li tib lub hauv paus, lav tias lub kauj tseem tsis muaj kev cuam tshuam thoob plaws hauv txoj kev tsim.

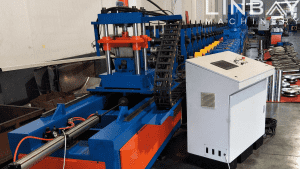

Roll forming tshuab

Lub tshuab tsim no siv cov qauv cam khwb cia hlau thiab lub tshuab tsav tsheb gearbox. Cov hlau kauj dhau los ntawm tag nrho ntawm 28 qhov chaw tsim khoom, ua rau deformation kom txog thaum nws phim cov specifications hauv cov duab kos.

Thaum cov neeg ua haujlwm teeb tsa qhov ntev ntawm PLC tswj vaj huam sib luag, cov chaw tsim khoom ntawm lub tshuab yob txoj haujlwm yuav cia li hloov mus rau txoj haujlwm raug, nrog rau qhov taw tes tsim txav mus rau hauv tandem nrog cov chais.

Txhawm rau kom muaj kev nyab xeeb thaum lub sijhawm txav ntawm cov chaw tsim khoom, ob lub ntsuas qhov deb tau muab tso rau ntawm ob sab laug thiab sab xis. Cov sensors sib haum mus rau qhov chaw sab nraud thiab sab hauv tshaj plaws uas cov chaw tsim khoom tuaj yeem hloov kho. Lawv ntes lub hauv paus ntawm cov chaw tsim khoom: lub innermost sensor tiv thaiv cov chaw tsim khoom los ntawm kev sib ze heev thiab ua rau cov menyuam sib tsoo, thaum lub sensor sab nraud tiv thaiv cov chaw tsim tawm los ntawm kev sib tsoo thiab poob.

Qhov saum npoo ntawm cov txheej txheem yog chrome-plated los tiv thaiv nws thiab txuas ntxiv lub neej ntawm cov chais.

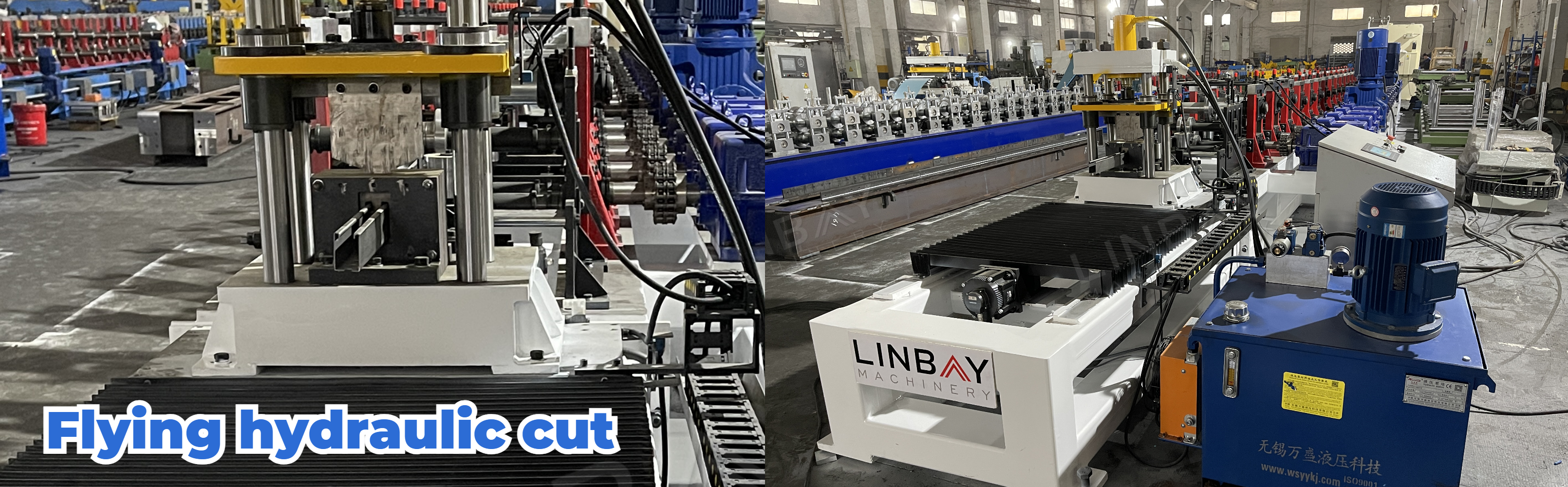

Flying hydraulic txiav

Lub hauv paus ntawm lub tshuab txiav tuaj yeem txav rov qab mus rau ntawm txoj kev, ua kom cov hlau kauj mus ua haujlwm tsis tu ncua los ntawm yob txoj kev tshuab. Qhov kev teeb tsa no tshem tawm qhov yuav tsum tau nres lub tshuab yob txoj kev, yog li ua kom tag nrho cov kab ntau lawm ceev.Qhov txiav hniav pwm yog tsim kom haum rau cov duab ntawm txhua qhov profile tshwj xeeb. Yog li ntawd, txhua qhov loj me yuav tsum muaj nws tus kheej cov txheej txheem txiav cov pwm.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj