Perfil

Cov kauj ruam beam plays lub luag haujlwm tseem ceeb hauvhnyav hnyav pallet racking systems, ncaj qha cuam tshuam lub zog thiab lub peev xwm thauj khoom ntawm tag nrho cov qauv.

Manufacturers feem ntau siv yob txoj kev tshuab nrog1.5-2mm kub dov los yog txias dov hlaulos tsim cov kauj ruam kab teeb. Txhawm rau txhim kho lawv txoj sia thiab tiv thaiv kev deformation los ntawm steel coil nro, vuam yog siv rau ntawm cov hlau coil pob qij txha. Ob qhov txheej txheem vuam siv ua haujlwm hauv kev lag luam yogMIG welder (raws li qhov no) thiab laser tag nrho welder.

Ob leeg MIG welder thiab laser tag nrho welder pab txhawb kev txhim kho kev ncaj ncees. Txawm li cas los xij, vim muaj kev qhia dav dav ntawm cov pob qij txha hauv kev vuam tag nrho, nws cov txiaj ntsig zoo tshaj qhov ntawm MIG vuam. Cov neeg siv khoom tuaj yeem xaiv txoj kev vuam raws li lawv cov peev txheej thiab cov khoom siv khib nyiab.

Cov ntaub ntawv tiag-Main Techinical Parameters

Flow daim ntawv qhia

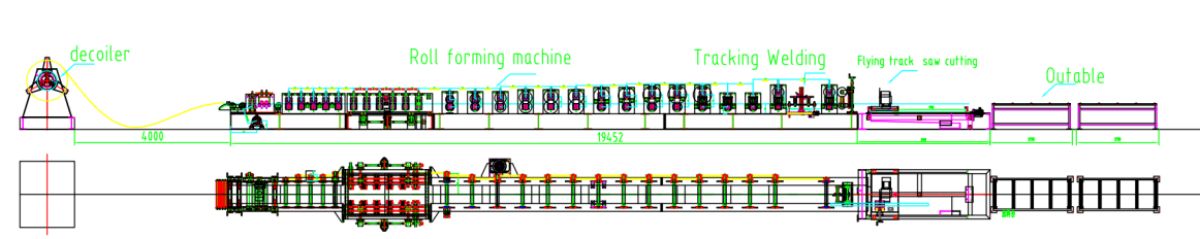

Kev tuav decoiler--Guiding--Leveler--Roll forming tshuab--Yav welder--Yav pom txiav--Out rooj

Main Techinical Parameters

1.Line ceev: 4-5 m / min, adjustable

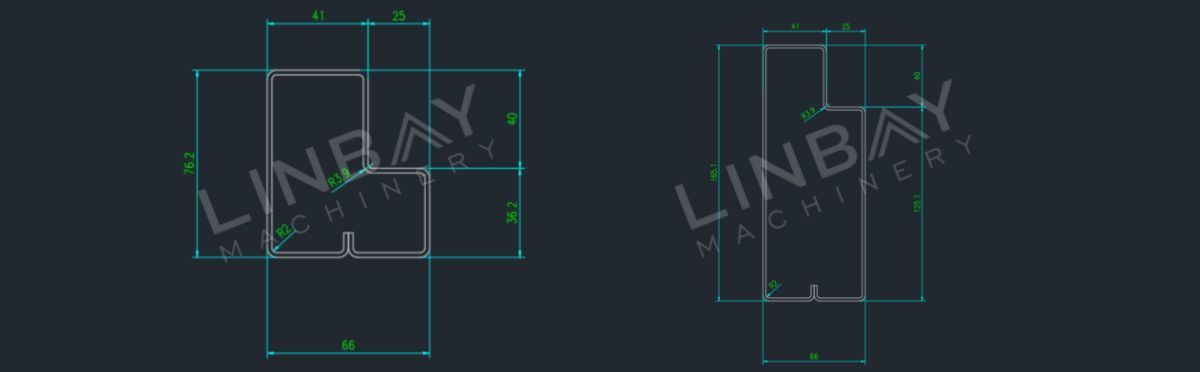

2.Profiles: Ntau qhov ntau thiab tsawg-qhov dav ntawm 66mm, thiab qhov siab sib txawv ntawm 76.2-165.1mm

3.Material thickness: 1.9mm (hauv qhov no)

4.Suitable khoom: Kub dov hlau, txias dov hlau, galvanized steel

5.Roll forming tshuab: cam khwb cia hlau qauv thiab saw tsav tsheb.

6. Tsis muaj. Qhov chaw nres tsheb: 26

7.Welding system: 2 * vuam torches, yob qub tsis nres thaum vuam.

8.Cutting system: Pom txiav, rollformer tsis nres thaum txiav.

9. Hloov loj: Tsis siv neeg.

10.PLC txee: Siemens system.

Cov ntaub ntawv tiag tiag-Kev piav qhia

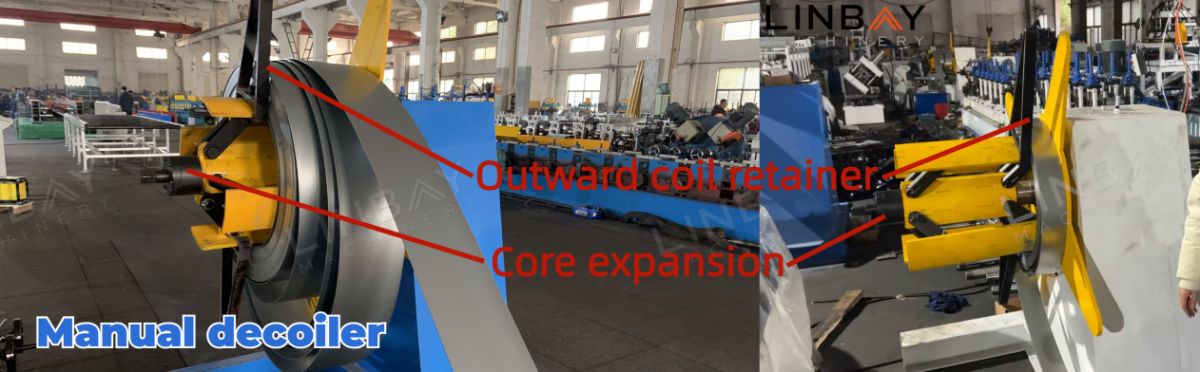

Phau ntawv decoiler

Phau ntawv decoiler nta anres ntaus ntawvtsim los kho core expansion nro nyob rau hauv qhov ntau ntawm φ490-510 mm, kom ntseeg tau tias du uncoiling ua haujlwm. Muab kev siv 1.9mm steel coil, muaj kev pheej hmoo ntawm kev cia li qhib thaum lub sij hawm uncoiling.Hais txog kev nyab xeeb nokev txhawj xeeb, ib lub xovxwm npab yog ntsia kom ruaj ntseg tuav lub steel kauj nyob rau hauv qhov chaw, thaum tiv thaiv steel hniav ntxiv los tiv thaiv kauj slippage. Qhov kev tsim no tsis tsuas yog muab cov kev daws teeb meem zoo xwb tab sis kuj tseem ceeb rau kev nyab xeeb hauv cov txheej txheem uncoiling.

Phau ntawv decoiler muajtsis muaj zog. Rau ntau dua qhov yuav tsum tau muaj peev xwm, peb muab ib qho kev xaivhydraulic decoilerpowered los ntawm qhov chaw nres tsheb hydraulic.

Kev taw qhia & Digital zaub

Kev taw qhia rollers ua lub luag haujlwm tseem ceeb hauv kev tswj xyuas kev sib raug zoo ntawm cov hlau kauj thiab cov tshuab, yog li tiv thaiv kev cuam tshuam ntawm cov kauj ruam nqaj thiab koom nrog cov txheej txheem yob txoj kev rautiv thaiv rebound deformation ntawm cov hlau. Qhov ncajntawm cov kauj ruam beam yog qhov tseem ceeb rau cov khoom lag luam zoo thiab cuam tshuam rau kev ua haujlwm ntawm kev ua haujlwm ntawm tag nrho racking system. Kev taw qhia rollers yog qhov chaw nyob tsis tau tsuas yog thaum pib ntawm lub tshuab yob txoj kev tab sis kujntawm ntau cov ntsiab lus raws tag nrho cov yob txoj kab, xyuas kom meej qhov kev sib raug zoo thoob plaws hauv cov txheej txheem ntau lawm.

Cov khoom siv digital tso saib yooj yimyooj yim kawntawm qhov tseeb txoj hauj lwm ntawm cov guiding rollers. Thiabntsuas qhov deblos ntawm txhua qhov kev taw qhia cov menyuam mus rau sab laug thiab sab xis ntawm lub yob txoj kev tshuab raug kaw rau hauv phau ntawv qhia, tso cai rau kev hloov kho yooj yim raws li cov ntaub ntawv no txawm tias muaj kev hloov pauv me ntsis thaum caij tsheb thauj mus los lossis ntau lawm.

Leveler

Tom qab qhov no, lub steel kauj nkag mus rau hauv lub leveler. Muab nws lub thickness ntawm 1.9 hli, nws yog ib qho tseem ceeb rautshem tawm tej curvature tam sim no nyob rau hauv steel kauj, yog li txhim kho nws cov flatness thiab parallelism rau qhov zoo ntawm cov kauj ruam beam. Nruab nrog 3 lub sab sauv thiab 4 lub kaum sab xis, cov qib qib ua tau zoo ua tiav lub hom phiaj no, ua kom pom kev zoo thiab sib luag rau cov txheej txheem yob tom ntej.

Roll Forming Tshuab

Nyob rau hauv lub plawv ntawm tag nrho cov kab ntau lawm lies lub yob txoj kev tshuab. Nruab nrog qhov sib txawv ntawm kev ceev tswj tau yooj yim los ntawm (Japanese hom) Yaskawa inverter, lub tshuab muaj ntau yam ceev ntawm 0 txog 10m / min, kom ntseeg tau tias kev hloov pauv mus rau ntau yam kev xav tau. Featuring 26 qhov chaw tsim khoom, nws sivphab ntsa vaj huam sib luag qauv thiab saw-tsav system, meticulously engineered xa precision thiab efficiency nyob rau hauv txoj kev tsim. Nrog nws cov cuab yeej siv thev naus laus zis thiab cov qauv tsim muaj zog, lub tshuab yob txoj kev ua haujlwm ua lub hauv paus ntawm kev ua tau zoo thiab kev tsim khoom hauv cov kab ntau lawm.

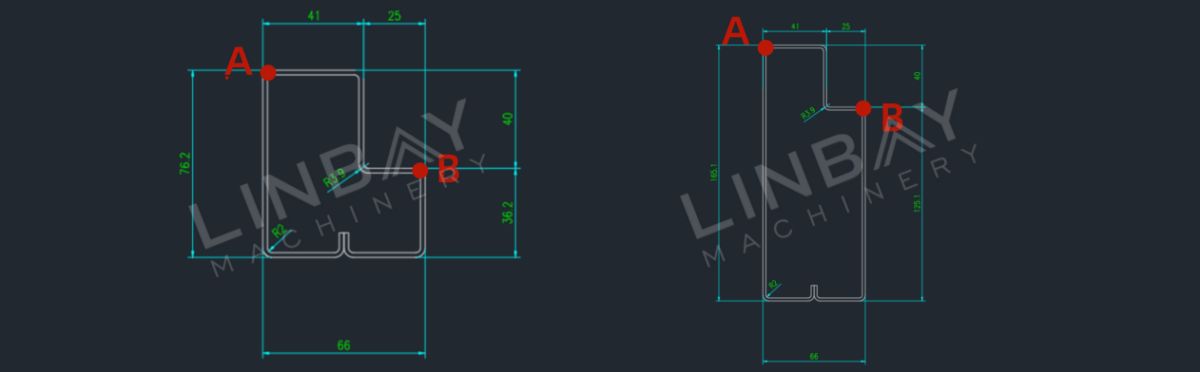

Muaj peev xwm ua tauntau qhov ntau thiab tsawg, nrog qhov dav ntawm 66mm thiab qhov siab ntawm 76.2 txog 165.1mm, qhov system no muaj kev hloov pauv hauv cov zis. Thaum nkag mus rau qhov xav tau hauv qab qhov dav thiab qhov siab rau hauv PLC tswj txee, cov chaw tsim khoom tau hloov kho rau cov haujlwm meej thiab hloov kho.Cov ntsiab lus tseem ceeb (A thiab B cov ntsiab lus), ua kom yooj yim hloov pauv hauv kwv yees li 10 feeb. Kev kho qhov siab sib haum mus rau qhov sib txawv ntawm cov ntsiab lus tseem ceeb (A thiab B cov ntsiab lus), ua rau cov khoom tsim cov kab teeb nrog qhov siab sib txawv.

Gcr15, high-carbon chromium-cov kabmob steel renowned rau nws hardness thiab hnav tsis kam, yog siv rau cov khoom ntawm txoj kev rollers. Txhawm rau kom ntev ntev, cov menyuam yaus tau siv chrome plating. Tsis tas li ntawd, shafts ua los ntawm 40Cr cov ntaub ntawv tau txais kev kho cua sov, ua kom muaj zog thiab ua kom muaj kev tsim kho zoo.

Flying MIG Welder

Txhawm rau kom ntev lub neej ntawm cov kauj ruam nqaj thiab tiv thaiv kev sib cais ntawm cov hlau coil pob qij txha, vuam yog ua haujlwm ntawm cov pob qij txha ntawm cov hlau coils hauv cov qauv dot. Qhov sib nrug ntawm txhua qhov chaw yog kho tau raws li cov neeg siv khoom xav tau. Tsis tas li ntawd, ob lub vuam torches raug teeb tsa los ua kom cov kab nrawm. Cov teeb ci notuaj yeem txav mus ib txhij nrog lub yob sib sau ceev, kom ntseeg tau kev ua haujlwm tsis tu ncua ntawm lub tshuab yob txoj kev.

Flying Saw Txiav

Tom qab yob txoj kev, cov kauj ruam beam nce mus rau lub tshuab txiav, siv lub tshuab txiav txiav vim qhov kaw zoo ntawm cov kauj ruam nqaj. Tshwj xeeb saw hniav lav siab precision thiab hardness, thaumib tug txias sprayertiv thaiv cov saw hniav, ncua lawv txoj sia. Txawm hais tias lub saw txiav ceev qeeb dua li hydraulic shearing,mobile muaj nuj nqi yog incorporated rau synchronize nrog lub yob txoj kev tshuab lub ntau lawm ceev, kom ntseeg tau tias kev ua haujlwm tsis cuam tshuam. Ntxiv mus, lub tshuab txiav txiav ua kom cov khoom pov tseg tsawg kawg thaum lub sij hawm hloov steel coil thiab profile txiav.

Encoder & PLC

Nyob rau hauv lub yob txoj kev tshuab, ib tug Japanese Koyo encoder yog hloov lub siab coil ntev mus rau hauv ib tug hluav taws xob teeb liab, uas yog kis mus rau lub PLC tswj txee. Lub tshuab hluav taws xob tswj, nyob hauv lub txee hluav taws xob tswj, ua kom tsis muaj qhov nrawm nrawm thiab qeeb qeeb thaum lub sijhawm txav mus rau pem hauv ntej thiab rov qab ntawm lub tshuab txiav, yog li ua tiav qhov tseeb txiav ntev. Cov txheej txheem tswj xyuas zoo no lav qhov ruaj khov thiab du vuam cov cim, tiv thaiv cov kab teeb ntawm kev tawg thiab ua kom ruaj khov, ua haujlwm zoo. Cov neeg ua haujlwm tau yooj yim tswj hwm qhov nrawm, teeb tsa qhov ntev, txiav ntev, thiab ntau dua los ntawm PLC screen. Tsis tas li ntawd, PLC tswj txee nta lub cim xeeb cia muaj nuj nqi rau cov khoom siv uas nquag siv thiab muab kev tiv thaiv tiv thaiv overload, luv luv Circuit Court, thiab theem poob, ua kom muaj kev ntseeg siab thiab kev nyab xeeb.

Cov lus ntawm PLC npo tuaj yeem hloov kho raws li cov neeg siv khoom xav tau.

Chaw nres tsheb Hydraulic

Peb qhov chaw nres tsheb hydraulic nta lub kiv cua txias kom ua kom cov cua sov kom zoo, ua kom muaj kev ua haujlwm ntev thiab txhim khu kev qha nrog tus nqi qis.

Warranty

Thaum cov khoom xa tuaj, hnub xa khoom yog qhia rau ntawm daim ntawv hlau, muab ob xyoos lav rau tag nrho cov kab ntau lawm thiab tsib xyoos lav rau cov menyuam thiab cov ncej.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj

1-300x168.jpg)