VIDEO

Perfil

Lub thawv beam stands raws li ib tug robust xaiv tailored rauhnyav-ua hauj lwmdaim ntawv thov. Tshwj xeeb, peb nthuav qhia aob-thooj hom kab teebrau koj qhov kev txiav txim siab. Feem ntau forged los ntawm txias-dov los yog kub-kuav los tiag steel nrog ib tug tuab ntawm 1.5 mus rau 2 hli, nws undergoes leej.yob txoj kevua ntej coated los xyuas kom meej qhov sib npaug ntawm qhov pom kev pom thiab lub zog muaj zog. Lub rooj sib txoos muaj kev ruaj ntseg koom nrogob daim ntawm C-zoo li steel profiles, ua rau lub cev muaj zog lub cev. Rau zus tau tej cov thawv kab teeb, lub txias yob txoj kev tshuab tshwm sim raws li cov kev xaiv, muab efficiency thiab precision.

Cov ntaub ntawv tiag-Main Techinical Parameters

Kev taw qhia cov menyuam yog qhov tseem ceeb hauv kev txhawb nqa kev sib raug zoo ntawm cov hlau kauj thiab cov tshuab, zooaverting distortionntawm lub thawv beam. Lawv kuj ua lub luag haujlwm tseem ceeb hauv kev tsim cov txheej txheem, tiv thaiv rov qab deformation ntawm steel kauj.Qhov ncajntawm lub thawv beam tuav ntau sway tshajcov khoom zoo thiab lub peev xwm load-bearingntawm tag nrho lub txee. Strategically positioned raws txoj kab sib sau, guiding rollers kom zoo zoo sib xws.Kev ntsuasntawm txhua qhov kev taw qhia cov menyuam qhov kev ncua deb mus rau ntug yog meticulously sau nyob rau hauv phau ntawv, ua kom seamless hloov raws li cov ntaub ntawv no, txawm nyob rau hauv cov kev tshwm sim ntawm me me displacement thaum lub sij hawm thauj los yog ntau lawm.

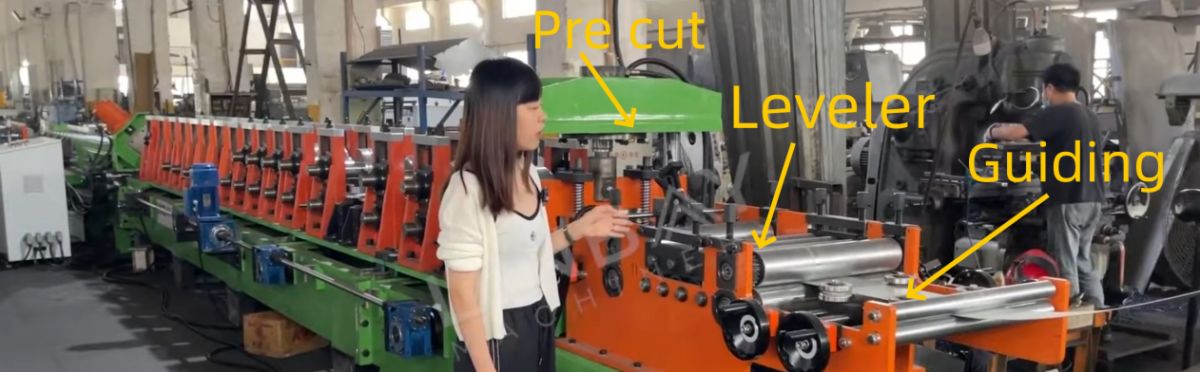

Leveler

Ua raws li cov theem ua ntej, cov hlau coil nce mus rau theem txheej txheem. Ntawm no, lub tshuab leveling mob siab rautshem tawm tej curvature tam sim no nyob rau hauv lub steel kauj, yog li txhim kho nws cov flatness thiab parallelism, thiaj li txhim kho qhov zoo ntawm cov khoom kawg - lub thawv beam. Nruab nrog 2 sab sauv thiab 3 qhov qis qis, lub tshuab leveling kom paub meej meej hauv kev npaj cov hlau kauj rau cov kauj ruam tom ntej.

Hydraulic Pre-txiav

Qhov no ntau lawm kab incorporateshydraulic pre-txiav ntaus ntawv,simplifying qhov hloov ntawm steel coils nrog txawv widths thiab thicknesses, ib txhijminimizing coil khib nyiab.

Roll Forming Tshuab

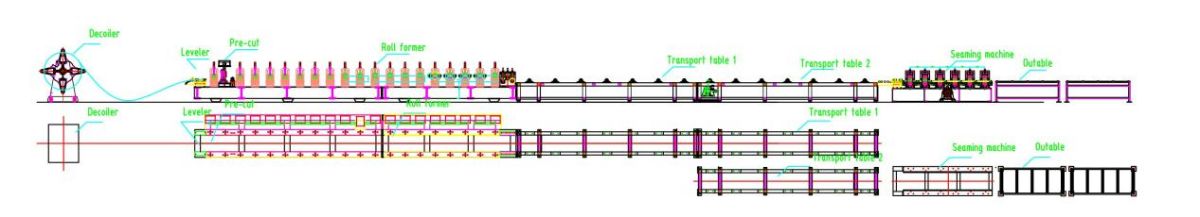

Flow daim ntawv qhia

Los ntawm txhais tes decoiler--Guiding--Leveler--Hydraulic ua ntej txiav--Roll txoj kev tshuab--Yav hydraulic txiav--Platform--Seaming tshuab--Out rooj

Main Techinical Parameters

1.Line ceev: 0-4 m / min, adjustable

2.Profiles: Ntau qhov ntau thiab tsawg-qhov siab ntawm 50mm, thiab qhov dav sib txawv ntawm 80, 100, 120mm

3. Khoom thickness: 1.5-2mm

4.Suitable khoom: Kub dov hlau, txias dov hlau, galvanized steel

5.Roll forming tshuab: cam khwb cia hlau stru

cture thiab chain tsav system.

6. Tsis muaj. Qhov chaw nres tsheb: 18

7.Cutting system: Hydraulic txiav, yob qub tsis nres thaum txiav.

8. Hloov loj: Tsis siv neeg.

9.PLC txee: Siemens system.

Cov ntaub ntawv tiag tiag-Kev piav qhia

Phau ntawv decoiler

Phau ntawv decoiler yog outfitted nrog abraking systemMeticulously engineered los tswj qhov nro ntawm lub unwinding yob thiab xyuas kom meej ib tug du unwinding txheej txheem. Txhawm rau txo qhov kev pheej hmoo ntawm kev rov qab sai sai, tshwj xeeb tshaj yog rau cov hlau coils tshaj 1.5 hli hauv thickness,ib armyog ua hauj lwm kom ruaj ntseg tuav lub steel kauj nyob rau hauv qhov chaw. Tsis tas li ntawd, steel tiv thaiv nplooj yog tsim los tiv thaiv coil slippage thaum unwinding. Qhov kev xav zoo no tsis yog tsuas yog txhim kho kev nyab xeeb tab sis kuj muajtus nqi-zoo, ua kom ntseeg tau thiab ua haujlwm tau zoo.

Hauv qhov xwm txheej no, phau ntawv decoilertsis muaj nws tus kheej lub zogyog ua hauj lwm. Rau ntau qhov xav tau ceev ntau lawm, peb muab kev xaivhydraulic decoilerpowered los ntawm qhov chaw nres tsheb hydraulic.

Kev taw qhia

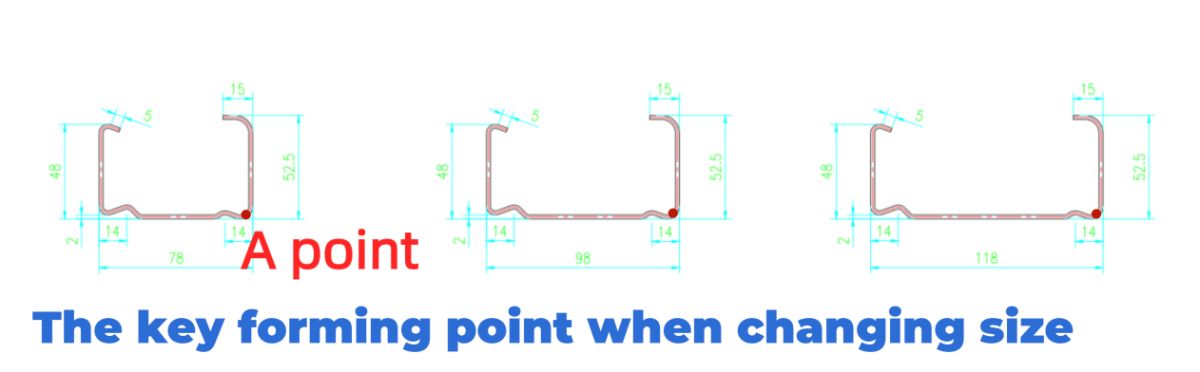

Nyob rau hauv lub plawv ntawm tag nrho cov kab ntau lawm yog cov yob txoj kev tshuab, ib tug indispensable tivthaiv. Tsim los ntawm ib qho khoom sivnrum hlau, lub tshuab no boasts ib tug robust qauv thiab yog tsav los ntawm ib tug txhim khu kev qhachain system. Nws versatility enables zus tau tej cov ntau thiab tsawg nrog qhov siab zoo ib yam. Cov neeg ua haujlwm tsis muaj zog nkag siab txog qhov ntev ntawm PLC tswj kev tshuaj ntsuam, ua rautsis siv neeg khontawm kev tsim cov chaw nres tsheb kom meej cov haujlwm. Feem ntau, cov neeg ua haujlwm paub txog yuav tsum tau kwv yees li 60 feeb los ua tiav cov txheej txheem hloov pauv, suav nrog ob qho tib si tsis siv neeg txav ntawm kev tsim cov chaw nres tsheb thiab phau ntawv hloov ntawm cov hlau kauj.

CovIb qho pointua raws li qhov tseem ceeb ntawm kev tsim cov ntsiab lus rau kev kho qhov dav. Raws li yob txoj kev chaw nres tsheb txav raws cov ntsia hlau, lawv dynamically hloov txoj hauj lwm ntawm no tseem ceeb txoj kev taw tes, ua rau zus tau tej covlub thawv kab teeb nrog ntau qhov dav.

Rau cov khoom ntawm kev sib sau cov menyuam, Gcr15 raug xaiv - cov pa roj carbon ntau chromium-cov kabmob steel muaj npe nrov rau nws qhov tshwj xeeb hardness thiab hnav tsis kam. Cov chais no tau txais chrome-plating los txhim kho lawv lub neej ntev, thaum lub shafts, crafted los ntawm 40Cr cov ntaub ntawv, undergo tshav kub kho rau ntxiv durability.

Flying Hydraulic Txiav

Tom qab ua tiav cov txheej txheem yob, cov hlau kauj maj mam ua raws li C-shaped profile. Nws yog ces precisely txiav mus rau qhov yuav tsum tau ntev los ntawm ib tug hydraulic txiav tshuab, tswj atxiav ntev yuam kev hauv 1 hli. Cov txheej txheem txiav no ua tau zoo txo qis steel coil khib nyiab thiab synchronizes nrog kev ceev ntawm cov yob txoj kev tshuab, kom ntseeg tau seamless thiab uninterrupted lag luam.

Platform

Thawj C-profile raug xa mus rau lub platform sab saud thiab tom qab ntawd thawb mus rau lub platform qis. Tom qab ntawd, qhov thib ob C-profile yog ua tib zoo thawb mus rau hauv nruab nrab txoj kab nqes, qhov twg lub tshuab flipping tig nws. Qhov kev txiav txim no ua kom zoo thiab ua kom zoo zoo ntawm ob C-profiles vertically.

Kev taw qhia cov menyuam ua kom muaj kev sib raug zoo ntawm ob C-profiles, thiab pneumatic laub rods thawb lawv mus rau hauv lub tshuab seaming.

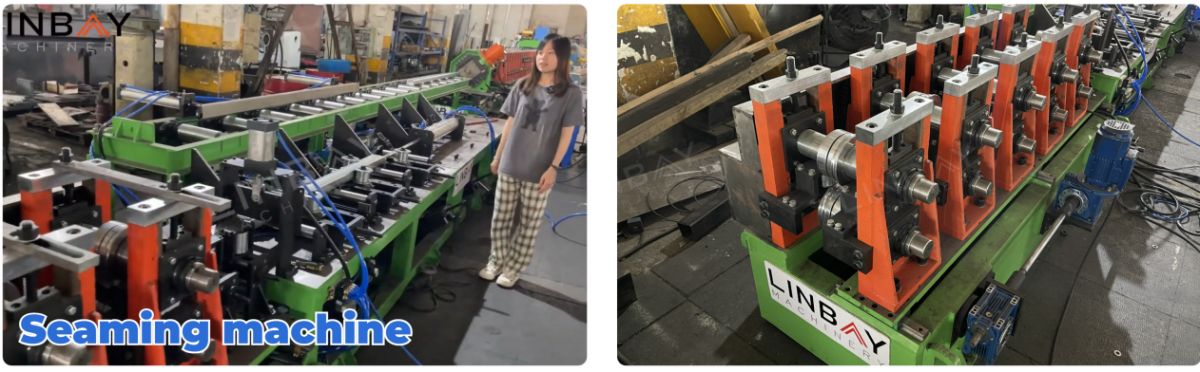

Seaming tshuab

Lub tshuab seaming tsom iav cov qauv ntawm lub tshuab yob txoj kev, boasting acam khwb cia-hlau qauv thiab saw tsav tsheb system. Nws autonomously kho qhov chaw nres tsheb seaming raws li lub thawv beam qhov dav. Qhov no innovationtshem tawm qhov xav tau rau ib tug welderRaws li kev lig kev cai, tus neeg ua haujlwm yuav tsum tau txuas ob lub C-profiles rau hauv lub thawv beam post-roll forming.

Encoder & PLC

Roll forming tshuab yog nruab nrog aJapanese Koyo encoder, uas yog hloov cov coil ntev mus rau hauv cov teeb liab hluav taws xob rau PLC tswj txee. Qhov no precision guaranteestxiav yuam kev yog txwv rau 1 hli, kom ntseeg tau cov kab teeb pom kev zoo thiab txo cov khoom pov tseg. Cov neeg ua haujlwm tuaj yeem tswj hwm qhov nrawm, teeb tsa qhov ntev, txiav ntev, thiab ntau dua ntawm PLC screen. Lub txee tseem khaws cov khoom siv feem ntau thiab muaj kev tiv thaiv kev tiv thaiv overload, luv luv Circuit Court, thiab theem poob. Kev teeb tsa lus ntawm PLC npo tuaj yeem hloov kho kom haum rau cov neeg siv khoom nyiam.

Chaw nres tsheb Hydraulic

Peb qhov chaw nres tsheb hydraulic, nruab nrog cov kiv cua txias, ua kom muaj cua sov zoo, ua kom muaj kev ua haujlwm ntev thiab txhim khu kev qha nrog tus nqi qis.

Warranty

Thaum khoom xa tuaj, daim ntawv teev npe qhia meej meej txog hnub xa khoom, muab aob-xyoo lav rau tag nrho cov kab ntau lawm thiab qhov zoo tshaj plaws tsib xyoos warranty rau cov menyuam thiab cov ncej.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj