yees duab

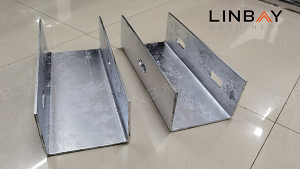

Profile

Strut channels nquag siv hauv cov ntawv thov xws li hnub ci vaj huam sib luag mounting, kav dej thiab kav dej, thiab HVAC systems. Standard strut channel qhov siab suav nrog21mm, 41mm, 52mm, 62mm, 71mm, thiab 82mm.Txoj kab uas hla ntawm txoj kab sib dhos hloov nrog qhov siab ntawm strut channel, nrog cov kab siab dua xav tau ntau qhov chaw tsim khoom. Cov channel no feem ntau yog tsim los ntawmkub dov hlau, txias-kuav los tiag steel, galvanized hlau, los yog stainless hlau,nrog thicknesses xws li los ntawm12 gauge (2.5mm) mus rau 16 gauge (1.5mm).

Lus Cim: Vim lub zog ntawm cov hlau tsis muaj zog ntau dua, qhov kev tsim lub zog xav tau ntau dua piv rau cov hlau tsis tshua muaj hlau thiab cov hlau tsis tu ncua ntawm tib lub thickness. Yog li ntawd, yob txoj kev tshuab tsim rau stainless hlau txawv ntawm cov uas siv rau cov pa roj carbon steel thiab galvanized hlau.

LINBAY muab cov kab ntau lawm uas muaj peev xwm ua tau ntau qhov ntev, uas tau muab faib rau hauv phau ntawv thiab hom kev siv tshuab ua haujlwm nyob ntawm qib ntawm automation yuav tsum tau hloov kho qhov ntev.

Cov ntaub ntawv tiag-Main Technical Parameters

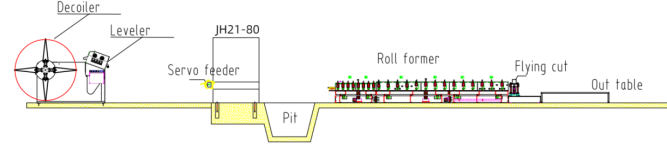

Flow daim ntawv: Decoiler--Servo feeder--Punch press--Guiding--Roll forming tshuab--Yav pom txiav--Out rooj

Cov ntaub ntawv tiag-Main Technical Parameters

1.Line ceev: 15m / min, adjustable

2.Suitable khoom: Kub dov hlau, txias dov hlau, galvanized steel

3.Material thickness: 1.5-2.5mm

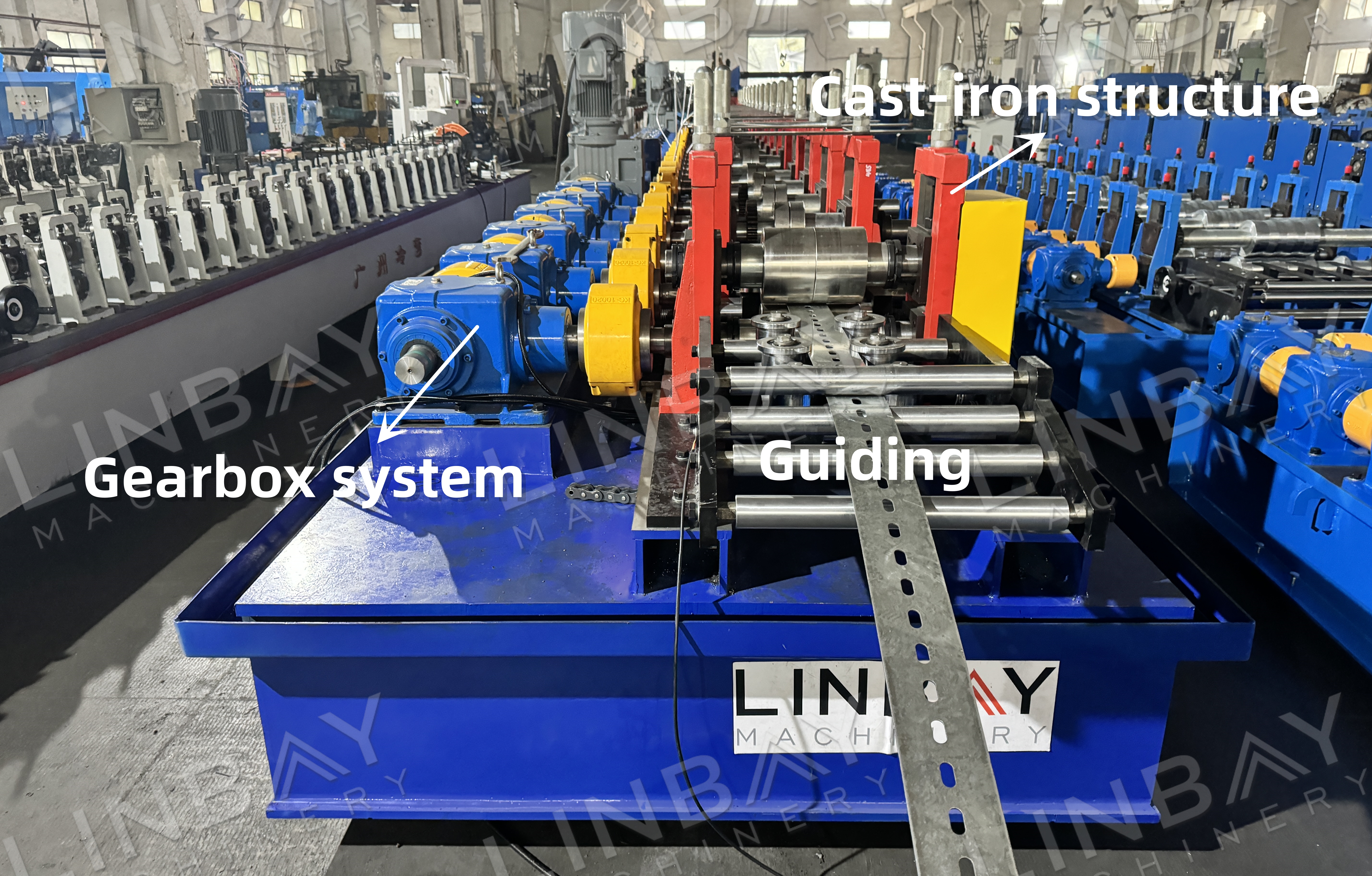

4.Roll forming tshuab: Cast-hlau qauv

5.Driving system: Gearbox tsav system

6.Cutting system: Flying pom txiav. Roll forming tshuab tsis nres thaum txiav

7.PLC txee: Siemens system

Cov ntaub ntawv tiag-Machinery

1.Hydraulic decoiler nrog qib * 1

2.Servo feeder * 1

3. Punch nias * 1

4. Roll forming tshuab * 1

5.Flying pom tej tshuab * 1

6.PLC tswj txee * 2

7.Hydraulic chaw nres tsheb * 2

8. Cov khoom seem lub thawv (Dawb) * 1

Thawv loj: 2x40GP + 1x20GP

Cov ntaub ntawv tiag tiag-Kev piav qhia

Decoiler nrog Leveler

Lub tshuab no ua ke nrog kev ua haujlwm ntawm lub decoiler thiab qib leveler, optimizing pem teb chaw siv. Leveling steel coils thicker dua 1.5 hli yog qhov tseem ceeb, tshwj xeeb tshaj yog rau kev xuas nrig ntaus ntawm qhov hauv cov kab strut. Lub leveler ua kom cov hlau kauj yog du thiab txo cov kev ntxhov siab sab hauv, ua kom yooj yim shaping thiab ncaj txoj kev.

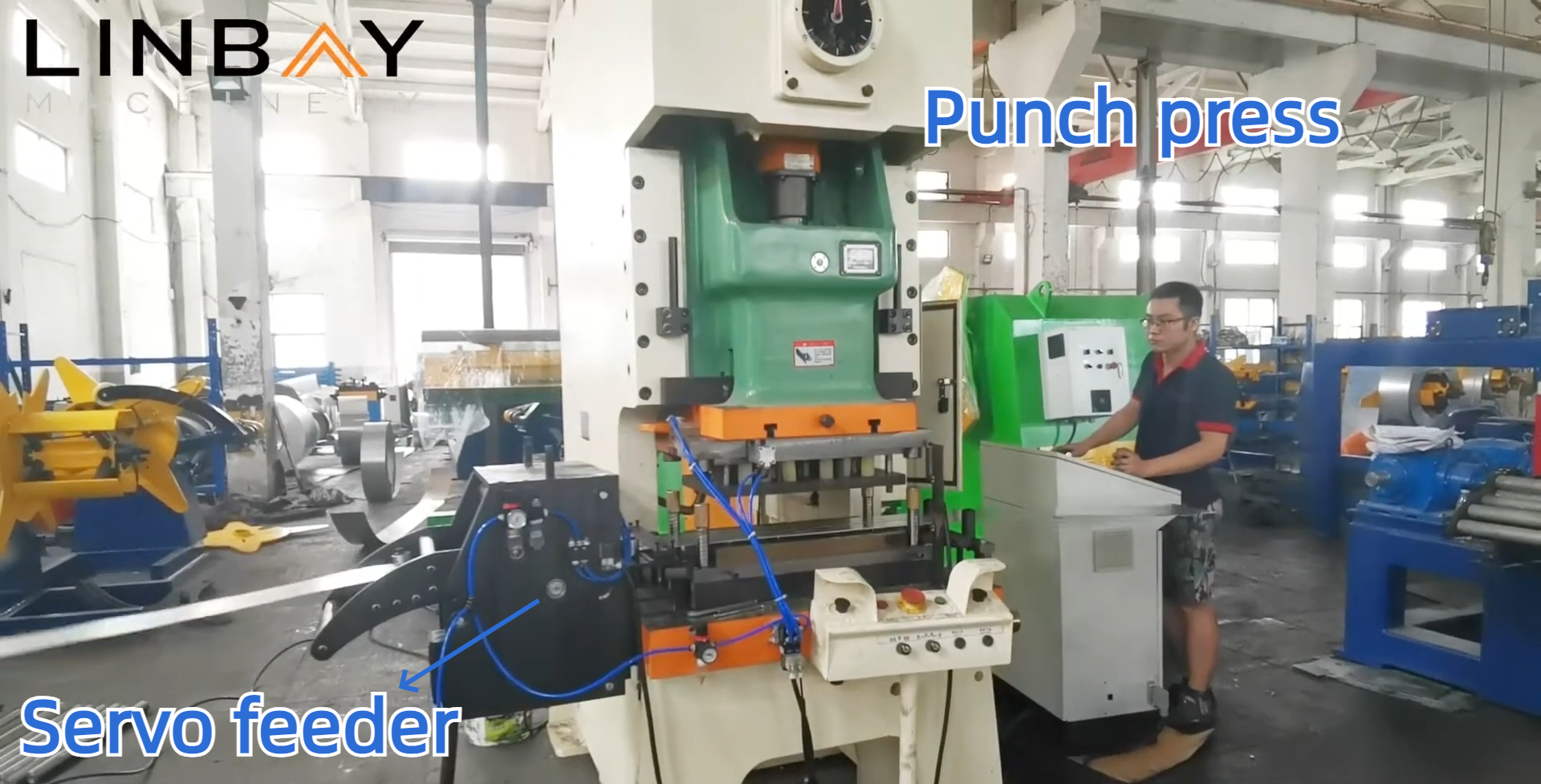

Servo Feeder

Lub servo feeder muaj npe rau nws siv lub servo lub cev muaj zog. Ua tsaug rau servo lub cev muaj zog qhov pib-nres qeeb qeeb, nws muaj qhov tshwj xeeb tshwj xeeb hauv kev pub steel coils. Qhov kev txiav txim siab no yog qhov tseem ceeb rau kev tswj xyuas nruj nruj thiab txo qis steel coil khib nyiab thaum lub sij hawm strut channel tsim. Tsis tas li ntawd, pneumatic clamps nyob rau hauv lub feeder ua ntej lub steel kauj thaum tiv thaiv nws nto los ntawm khawb.

Punch Xovxwm

Lub punch xovxwm yog ua haujlwm los tsim qhov hauv cov hlau kauj, qhov tseem ceeb rau kev txuas cov ntsia hlau thiab cov txiv ntseej kom ruaj ntseg cov strut. Cov punch xovxwm no ua haujlwm sai dua li kev sib koom ua ke hydraulic punch (mounted ntawm tib lub hauv paus raws li lub tshuab yob txoj kev) thiab ib qho hydraulic punch. Peb siv cov punch presses los ntawm cov npe nrov Suav teb Yangli, uas muaj ntau lub chaw ua haujlwm thoob ntiaj teb, ua kom muaj kev pab cuam tom qab muag tau yooj yim thiab yooj yim rau kev hloov qhov chaw.

Kev taw qhia

Qhia cov chais kom cov hlau kauj thiab cov cav tov ua raws tib qhov chaw nruab nrab, kom ntseeg tau qhov ncaj ntawm cov strut channel. Qhov kev sib tw no yog qhov tseem ceeb rau kev sib piv cov strut channel nrog lwm cov profiles thaum lub sij hawm installation, ncaj qha cuam tshuam rau kev ruaj ntseg ntawm tag nrho cov qauv tsim.

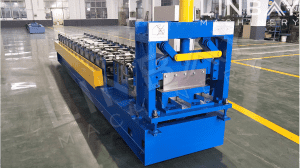

Roll Forming Tshuab

Roll forming tshuab boasts ib tug cam khwb cia-hlau qauv ua los ntawm ib daim hlau, muab tshwj xeeb durability. Lub sab sauv thiab sab yob siv zog los tsim cov hlau kauj, uas tau tsav los ntawm lub gearbox kom xa lub zog txaus rau kev tsim cov txheej txheem.

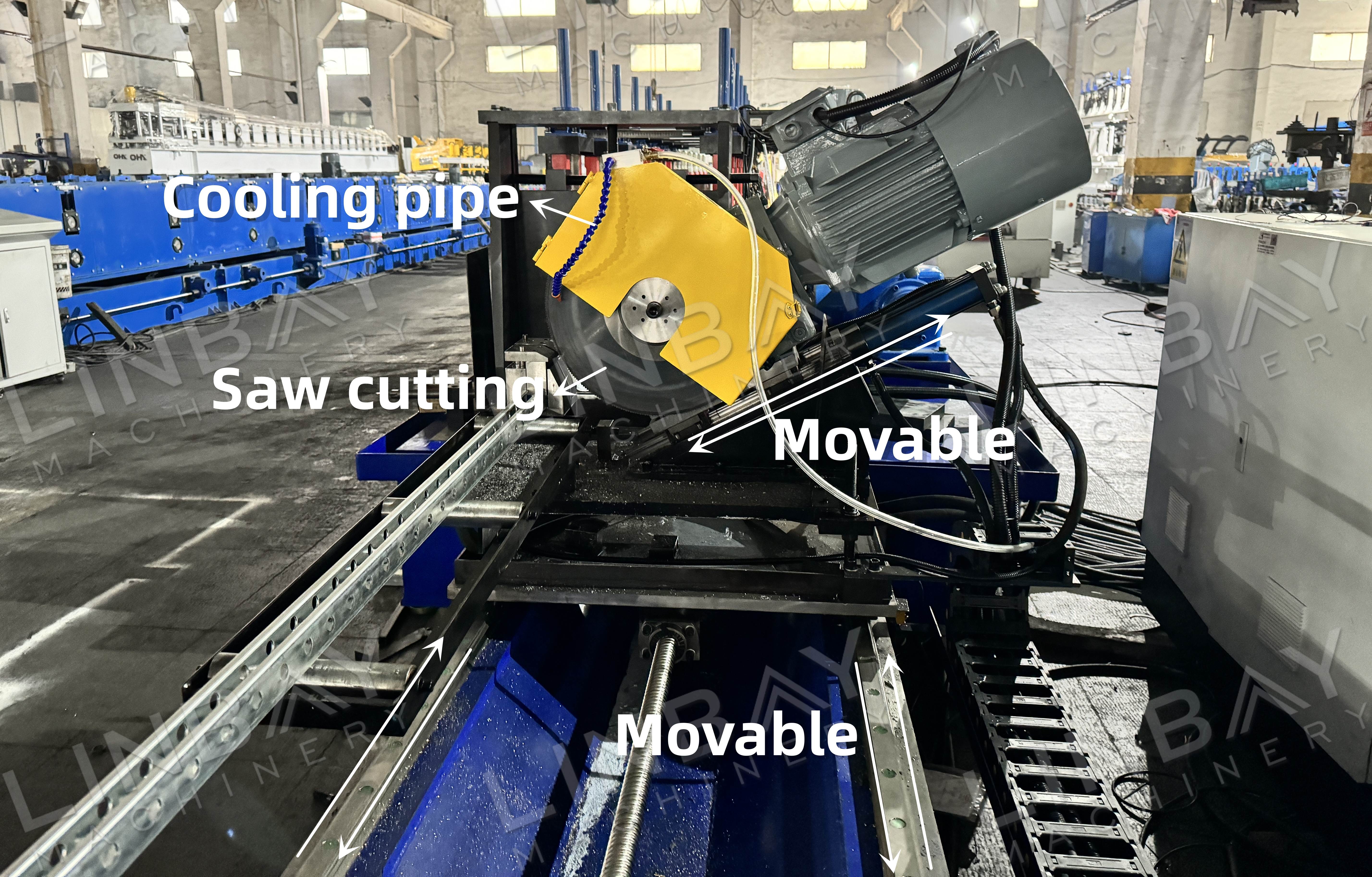

Flying Saw Txiav

Lub flying saw cutter lub carriage accelerates synchronize nrog ceev ntawm lub txav strut raws, uas kuj yog qhov ceev ntawm yob txoj kev tshuab. Qhov no ua rau kev txiav yam tsis muaj kev cuam tshuam cov txheej txheem ntau lawm. Qhov kev daws teeb meem zoo no yog qhov zoo tshaj plaws rau kev ua haujlwm siab ceev thiab tsim cov khib nyiab tsawg.

Thaum lub sij hawm txiav cov txheej txheem, pneumatic lub zog txav cov saw hniav hauv paus mus rau strut channel, thaum lub zog hydraulic los ntawm qhov chaw nres tsheb hydraulic tsav cov kev sib hloov ntawm cov saw hniav.

Chaw nres tsheb Hydraulic

Lub chaw nres tsheb hydraulic muab lub zog xav tau rau cov khoom siv xws li hydraulic decoiler thiab hydraulic cutter thiab nruab nrog cov kiv cua txias kom ntseeg tau tias muaj cua sov zoo. Nyob rau hauv cov huab cua kub, peb xav kom loj lub hydraulic reservoir los txhim kho cov cua kub dissipation thiab ua kom lub ntim ntawm cov kua muaj rau txias. Cov kev ntsuas no pab tswj kev ua haujlwm ruaj khov thaum lub sijhawm siv ntev, yog li ua kom muaj kev ntseeg siab thiab ua haujlwm ntawm cov yob tsim cov kab ntau lawm.

PLC Tswj txee & Encoder

Encoders ua lub luag haujlwm tseem ceeb hauv kev xa tawm tswv yim ntawm txoj haujlwm, nrawm, thiab synchronization. Lawv hloov qhov ntsuas qhov ntev ntawm cov hlau kauj mus rau hauv cov teeb liab hluav taws xob, uas xa mus rau PLC tswj txee. Cov neeg ua haujlwm siv lub txee tswj cov zaub los kho qhov tsis xws li kev tsim khoom nrawm, tso zis ib lub voj voog, thiab txiav ntev. Ua tsaug rau qhov tseeb kev ntsuas thiab cov lus tawm tswv yim los ntawm encoders, lub tshuab txiav tuaj yeem ua tiav qhov raug txiav hauv ± 1mm.

Flying hydraulic txiav VS Flying saw txiav

Txiav Hniav: Txhua qhov ntev ntawm lub tshuab txiav hydraulic yuav tsum tau nyias nyias nyias. Txawm li cas los xij, txiav txiav tsis txwv los ntawm qhov ntev ntawm cov strut channels.

Hnav thiab tsim kua muag: Pom cov hniav feem ntau muaj kev hnav sai dua piv rau hydraulic txiav hniav thiab yuav tsum tau hloov ntau zaus.

Suab nrov: Pom txiav zoo li nrov dua li hydraulic txiav, uas yuav xav tau ntxiv kev ntsuas suab nrov hauv thaj chaw tsim khoom.

Khib nyiab: Ib lub tshuab txiav hydraulic, txawm tias thaum ntsuas tau zoo, feem ntau ua rau cov khib nyiab tsis tuaj yeem ntawm 8-10mm ib ntus. Ntawm qhov tod tes, lub saw cutter tsim zero pov tseg.

Kev Kho: Pom cov hniav xav tau lub tshuab ua kom txias los tswj cov cua sov uas tsim los ntawm kev sib txhuam, ua kom muaj kev sib txhuam thiab ua tau zoo. Hauv qhov sib piv, hydraulic txiav tswj qhov kub thiab txias dua.

Cov Khoom Siv Txwv: Cov hlau tsis muaj steel muaj lub zog ntau dua li cov pa roj carbon steel. Thaum ua haujlwm nrog stainless hlau, tsuas yog txiav txiav yog tsim rau kev ua cov khoom.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj