Kev piav qhia

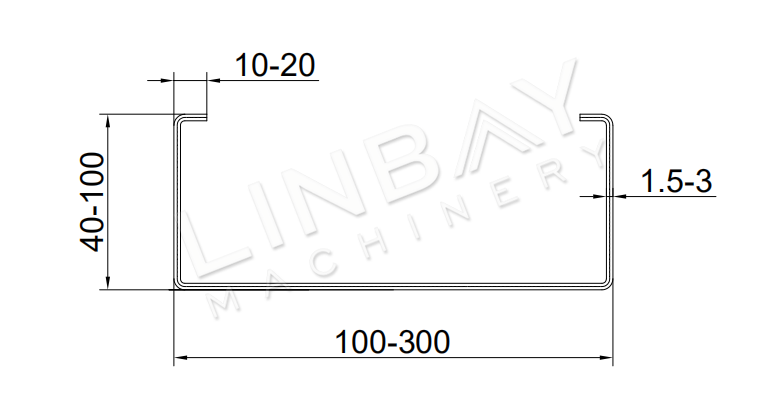

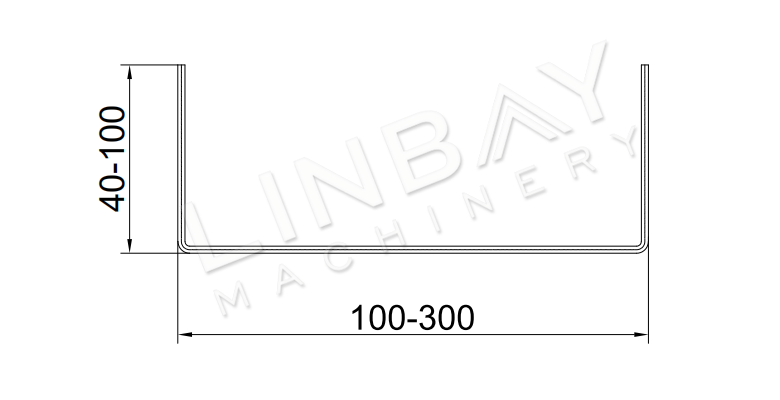

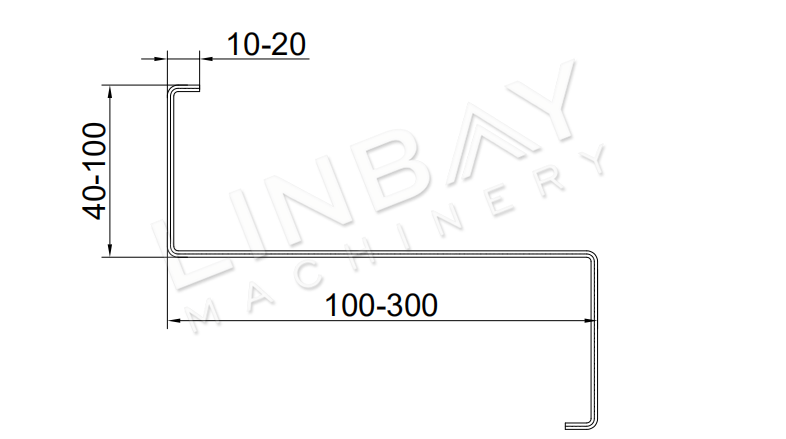

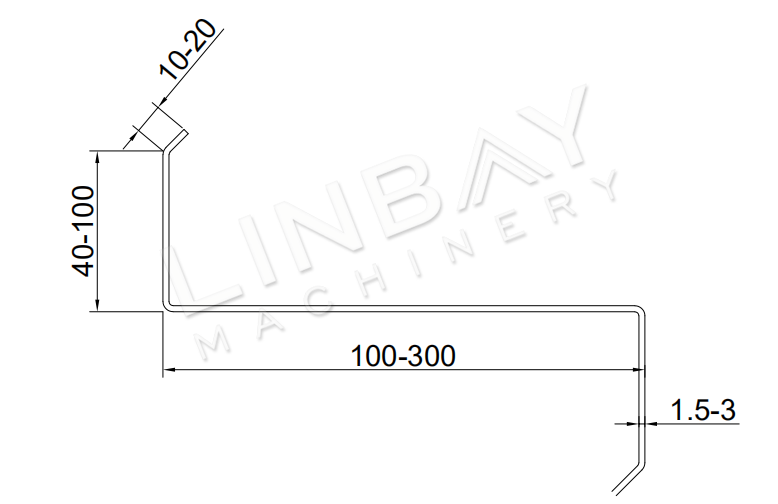

Purlin yob txoj kev tshuabyog qhov nrov tshaj plaws thiab muaj kev siv dav hauvHlau Tsev Systems, Loj RoofingSolutions, Kev tsim khothiabRenovation ProjectslwmPurlin yob txoj kev tshuabtuaj yeem tsim tauC purlin, U purlin, Z purlin, machineable loj ntau yam raws li nram no: Dav: 0-300mm, Qhov siab: 50-100mm, Thickness: 1.5-3mm. Cov khoom siv raw tuaj yeem yog: txias-kuav los tiag steel, Galvanized steel, PPGI, high-tensil steel. Cov purlins tiav lawm sib ntsibJIS G tus qauv, ASTM International Standard, AS / NZS International Standardetc. Tsuas yog qhov zoo tshaj plaws purlin tshuab rau koj qhov project.

Raws li koj cov seem profile, qhov loj me, thickness ntau peb tuaj yeem muab cov kev daws teeb meem sib txawv rau kojpurlin yob txoj kev tshuabrau cov chaw tsim khoom ua tiav ntau yam ntawm cov qauv purlins (qhov siab thiab dav hloov pauv siv lub tshuab tsis siv neeg los ntawm cov motors):

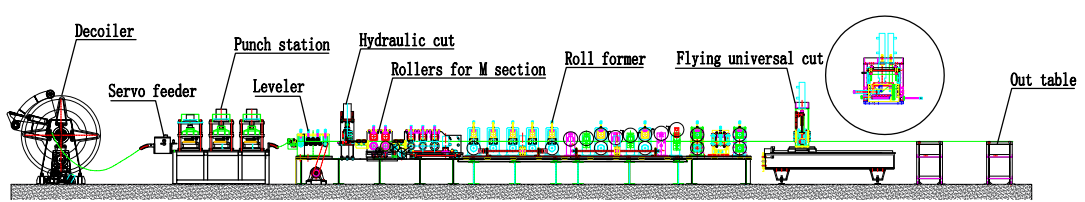

Tsuas yog los tsim C / U ntu, hloov sijhawm: ob peb feeb

C / U / Z ntu - phau ntawv hloov tag nrho kab ntawm C rau Z, hloov sijhawm: 10 feeb

C / U / Z / M seem-kev hloov pauv 4 chaw nres tsheb los ntawm C rau Z, hloov sijhawm: 2 feeb

C / U / Z / M seem-automatically hloov ntawm C rau Z, hloov lub sij hawm: ob peb vib nas this

Hais txog chav txiav, koj tuaj yeem xaiv qhov txiav ua ntej, xa ntawv txiav lossis ob qho tib si. Gearbox tsav system nrog cam khwb cia hlau stands yog ntau ruaj thiab pom zoo.

Yog tias koj tsuas yog xav tau tsim ob peb qhov ntau thiab tsawg, peb kuj xav kom hloov lub tes tsho manually, nws pheej yig dua.

Peb ua cov kev daws teeb meem sib txawv raws li cov neeg siv khoom kos duab, siab ntev thiab peev nyiaj, muab cov kev pabcuam ib-rau-ib, hloov tau rau koj txhua qhov kev xav tau. Txawm hais tias koj xaiv kab twg, qhov zoo ntawm Linbay Machinery yuav xyuas kom koj tau txais kev ua haujlwm zoo kawg nkaus.

Daim ntawv thov

Case tiag A

Nqe lus piav qhia:

Qhov noC / Z / U / M purlin yob txoj kev tshuabyog peb cov kev tsim kho tshiab hauv 2018. Lub tshuab no tau raug xa tawm mus rau Mumbai, Is Nrias teb. Lub tshuab zoo heev no tuaj yeem ua tauTshooj C, U ntu, M ntu thiab Z ntu purlinsnrog thickness 1.5-4mm. Lub purlin kab yog nruab nrog servo feeder, leveler thiab tsis siv neeg dav-hloov thiab qhov siab-hloov system, kuj los ntawm C rau Z tsuas yog yuav tsum tau hloov 4 chaw nres tsheb manually nrog hloov log. Nws tuaj yeem ua haujlwm tag nrho nrog ib tus neeg teb xov tooj yooj yim hauv 2 feeb. Linbay Machinery yog koj qhov kev xaiv zoo tshaj plaws raupurlin yob txoj kev daws.

Case tiag B

Nqe lus piav qhia:

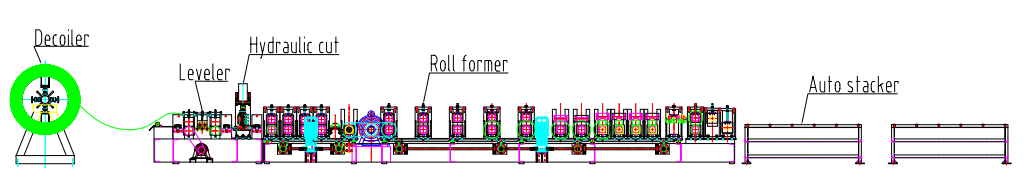

Qhov noCZ purlin ceev hloov yob txoj kev tshuabyog cov kab ntau lawm. Peb muaj 10 xyoo ntawm kev paub hauv lub tshuab no. Nws yog pheej yig dua, kev lag luam thiab nws yog peb tus neeg muag khoom zoo tshaj plaws. Nws siv cov txheej txheem ua ntej txiav kom tsis txhob hloov ntau cov hniav, uas txuag sijhawm rau koj. Qhov ntau thiab tsawg tuaj yeem hloov tau los ntawm lub cev muaj zog. Hloov lub sij hawm ntawm C rau Z yuav tsum tau 10 feeb. Linbay Machinery yog koj qhov kev xaiv zoo tshaj plaws rau purlin yob txoj kev daws teeb meem.

Tag nrho cov kab ntau lawm ntawm Purlin yob txoj kev tshuab

Technical Specifications

| Purlin Roll Forming Tshuab | ||

| Machinable Khoom: | A) Galvanized Coil | Thickness (MM): 1.5-3 |

| B) PIB | ||

| C) Carbon steel kauj | ||

| Yield zog: | 250-550 Mpa | |

| Tensil stress: | G350 Mpa-G550 Mpa | |

| Decoiler: | Phau ntawv decoiler | * Hydraulic decoiler (yeem) |

| Punching system: | Hydraulic punching chaw nres tsheb | * Punching xovxwm (yeem) |

| Tsim chaw nres tsheb: | 18-20 chaw nres tsheb | |

| Main tshuab lub cev muaj zog hom: | Shanghai Dedong (Sino-Germany Hom) | * Siemens (yeem) |

| Tsav system: | Chain tsav | * Gearbox tsav (Yeem) |

| Tshuab qauv: | Phab ntsa vaj huam sib luag chaw nres tsheb | * Forged Hlau chaw nres tsheb (Yeem) |

| Kev sib sau ceev: | 10-20 (M / min) | * Los yog raws li koj cov duab kos duab |

| Rollers cov khoom siv: | Steel #45 | * GCr 15 (yeem) |

| Txiav qhov system: | Pre-txiav | * Post- universal txiav (yeem) |

| Frequency changer hom: | Yaskawa | * Siemens (yeem) |

| PLC hom: | Panasonic | * Siemens (yeem) |

| Fais fab mov: | 380V 50Hz | * Los yog raws li koj xav tau |

| Tshuab xim: | Industrial xiav | * Los yog raws li koj xav tau |

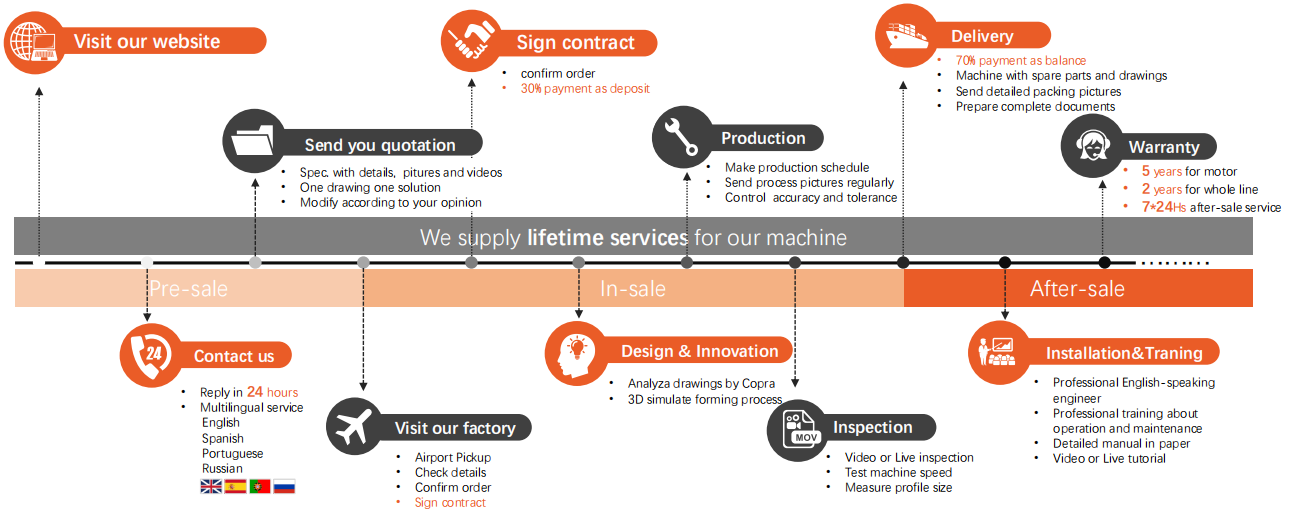

Kev yuav khoom

Q&A

1. Q: Koj muaj kev paub dab tsi hauv kev tsim khoompurlin yob txoj kev tshuab?

A: Peb tau exportedC / Z purlin yob txoj kev tshuabmus rau Is Nrias teb, Serbia, UK, Peru, Argentina, Chile, Hondulas, Bolivia, Tim lyiv teb chaws, Poland, Russia, Spain, Romania thiab lwm yam. Nws yog qhov nrov tshaj plaws yob txoj kev tshuab ntawm tag nrho cov.

Hauv Kev Tsim Kho Kev Lag Luam, peb muaj peev xwm tsim tau ntau lub tshuab zoo lilub ntsiab channel yob txoj kev tshuab, furring channel yob txoj kev tshuab, qab nthab yob txoj kev tshuab, phab ntsa lub kaum sab xis yob formign tshuab, lub teeb gauge steel yob txoj kev tshuab, drywall yob txoj kev tshuab, stud yob txoj kev tshuab, khiav yob txoj kev tshuab, hlau lawj (pem teb lawj) yob txoj kev tshuab, vigacero yob txoj kev tshuab, ru tsev / phab ntsa yob forming tshuab,lwm.

Tsuas yog qhov zoo tshaj plaws steel ncej tshuab rau koj qhov project.

2. Q: Muaj pes tsawg qhov ntau thiab tsawg tuaj yeem tsim lub tshuab no?

A: Lub tshuab no tuaj yeem tsim C purlin, Z purlin, U purlin, Sigma purlin, thiab txhua ntu tuaj yeem tsim ntau qhov ntau thiab tsawg, qhov dav yog 80-300mm, qhov siab ntau yog 50-100mm, pom zoo thickness ntau yog 1.5-3mm. Nws yog koj qhov zoo tshaj plaws thiab pheej yig xaiv rau steel ncej.

3. Q: Lub sijhawm xa khoom ntawm cable tais tshuab yog dab tsi?

A: 60 hnub rau 70 hnub nyob ntawm koj daim duab.

4. Q: Koj lub tshuab ceev yog dab tsi?

A: Nquag sib sau ceev yog nyob ib ncig ntawm 20m / min (kho tau) nrog ya txiav rau thickness 1.5mm. Rau 3 hli, kev sib sau ceev yog qis dua, nyob ib ncig ntawm 15m / min.

5. Q: Koj tuaj yeem tswj koj lub tshuab precision thiab zoo li cas?

A: Peb tsis pub leejtwg paub los ua qhov tseeb yog tias peb lub Hoobkas muaj nws tus kheej cov kab ntau lawm, los ntawm kev xuas nrig ntaus pwm mus rau kev ua cov menyuam, txhua qhov khoom siv ua tiav ntawm nws tus kheej los ntawm peb lub Hoobkas tus kheej. Peb nruj me ntsis tswj qhov raug ntawm txhua kauj ruam los ntawm kev tsim, ua, sib dhos rau kev tswj kom zoo, peb tsis kam txiav cov fab.

6. Q: Koj qhov kev pab cuam tom qab muag yog dab tsi?

A: Peb tsis txhob yig muab lub sijhawm lav rau koj ob xyoos rau tag nrho cov kab, tsib xyoos rau lub cev muaj zog: Yog tias yuav muaj teeb meem zoo los ntawm cov khoom tsis yog tib neeg, peb yuav daws nws tam sim ntawd rau koj thiab peb yuav npaj rau koj 7X24H. Ib qho kev yuav khoom, kev saib xyuas lub neej rau koj.

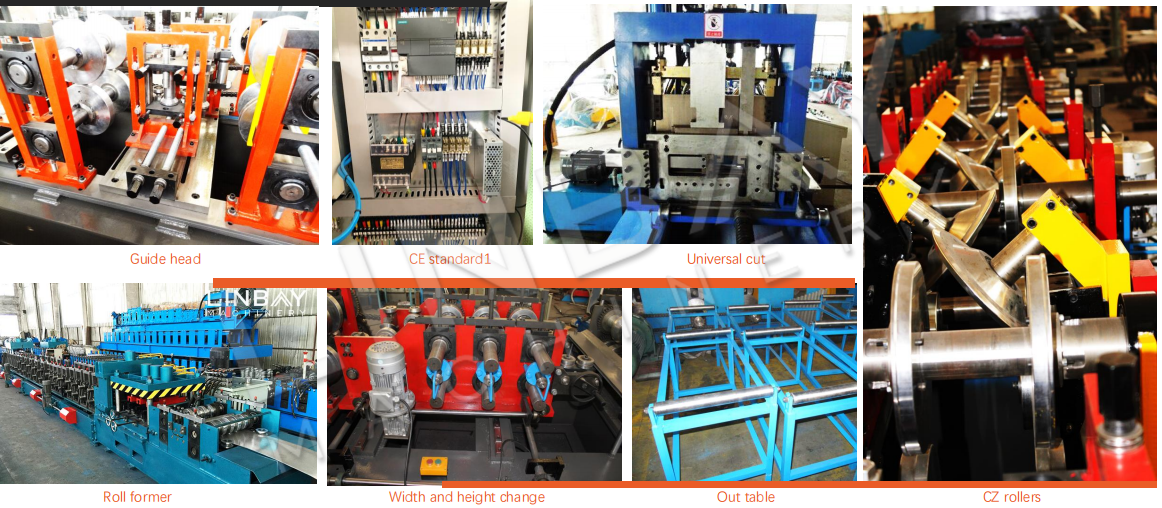

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj